3.

Burner Circuit.

In approximately 30 seconds, the igniter at-

tains ignition temperature and ignition is made. The heat from

the burner flame causes the sensor contacts (located on burner

housing beside the igniter) to open. A circuit is then complet-

ed through the secondary valve coil, opening the valve and al-

lowing gas to flow.

4.

Momentary Power Interruption.

Upon resumption of pow-

er, sensor contacts will still be open, permitting secondary

valve to open. However, with the secondary coil in the circuit,

the booster coil cannot draw enough current to open the split-

coil valve. When sensor contacts do reclose, the secondary

valve will close, and the burner system will be in the normal

pre-ignition circuit.

5.

Flame Failure.

In case of flame failure, the sensor contacts

will re-close in about 45 seconds. This will close the secon-

dary valve and the burner system will be in the normal pre-

ignition circuit.

6.

Ignition Failure.

If flame is not established as sensor contacts

open, secondary valve will remain open until sensor contacts

re-close. Sensor will continue to recycle the igniter and secon-

dary valve (about once per minute) until ignition is made or

dryer is turned off.

DRY1885S_SVG

1 -

3

4 5

4

6

5

1

3

7

2

1.

Terminal 1

2.

Terminal 2

3.

Terminal 3

4.

Terminal 4

5.

Terminal 5

6.

Secondary Coil

7.

Holding and Booster Coil

Figure 17

DRY1886S_SVG

11

4

3

2

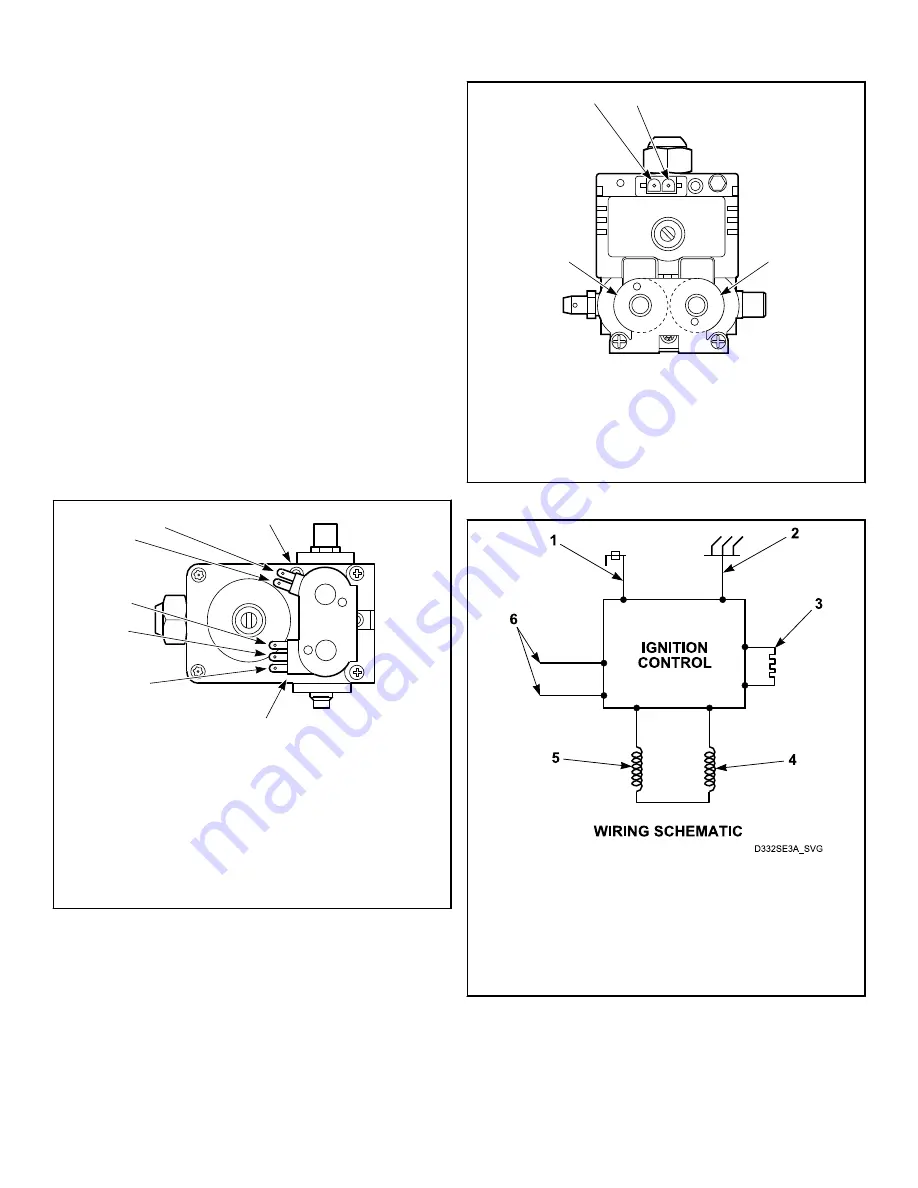

1.

Terminal 1

2.

Terminal 2

3.

Redundant Coil

4.

Main Coil

Figure 18

1.

Flame Sensor

2.

Ground

3.

Igniter

4.

Redundant Coil

5.

Main Coil

6.

220/240 Volt, 50 Hertz Electrical Supply Line

Figure 19

Electrical Circuit To Ignition System

(Gas Models)

Test Procedures

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

60

Part No. D515519R3

Summary of Contents for BD3NGBGS303EW01

Page 2: ......