1. While supporting the access panel, remove two screws from

bottom edge of access panel.

2. Gently lower the access panel to disengage locators from bot-

tom edge of front panel.

3. Close main gas shut-off valve. Refer to

.

4. Remove valve wire harness disconnect block from the hold-

ing and booster coil. Refer to

5. Plug dryer power cord into wall receptacle, and start the dryer

in a heat setting (refer to dryer Operating Instructions).

6. Set test meter to read AC voltage and apply meter probes into

terminals on the dryer harness plug that would correspond to

terminals “1” and “2” on the coil. Refer to

and

. Meter should register line voltage in all temperature

settings, except NO HEAT which should read “zero” VAC.

7. If meter does not read line voltage in step “f”, check motor

switch, thermostats, fabric switch, or control.

WARNING

To reduce the risk of fire, explosion and electric

shock, close the valve in the gas supply line to the

gas dryer and disconnect the electrical power unless

gas or power supplies are required to perform test

procedure.

W263

Gas Valve Coils Check (Gas Models)

1. While supporting the access panel, remove two screws from

bottom edge of access panel.

2. Gently lower the access panel to disengage locators from bot-

tom edge of front panel.

3. Close main gas shut-off valve. Refer to

.

4. Remove disconnect blocks from gas valve coils.

5. Set test meter to read Ohms and put meter probes to terminals

shown in

,

lowing chart.

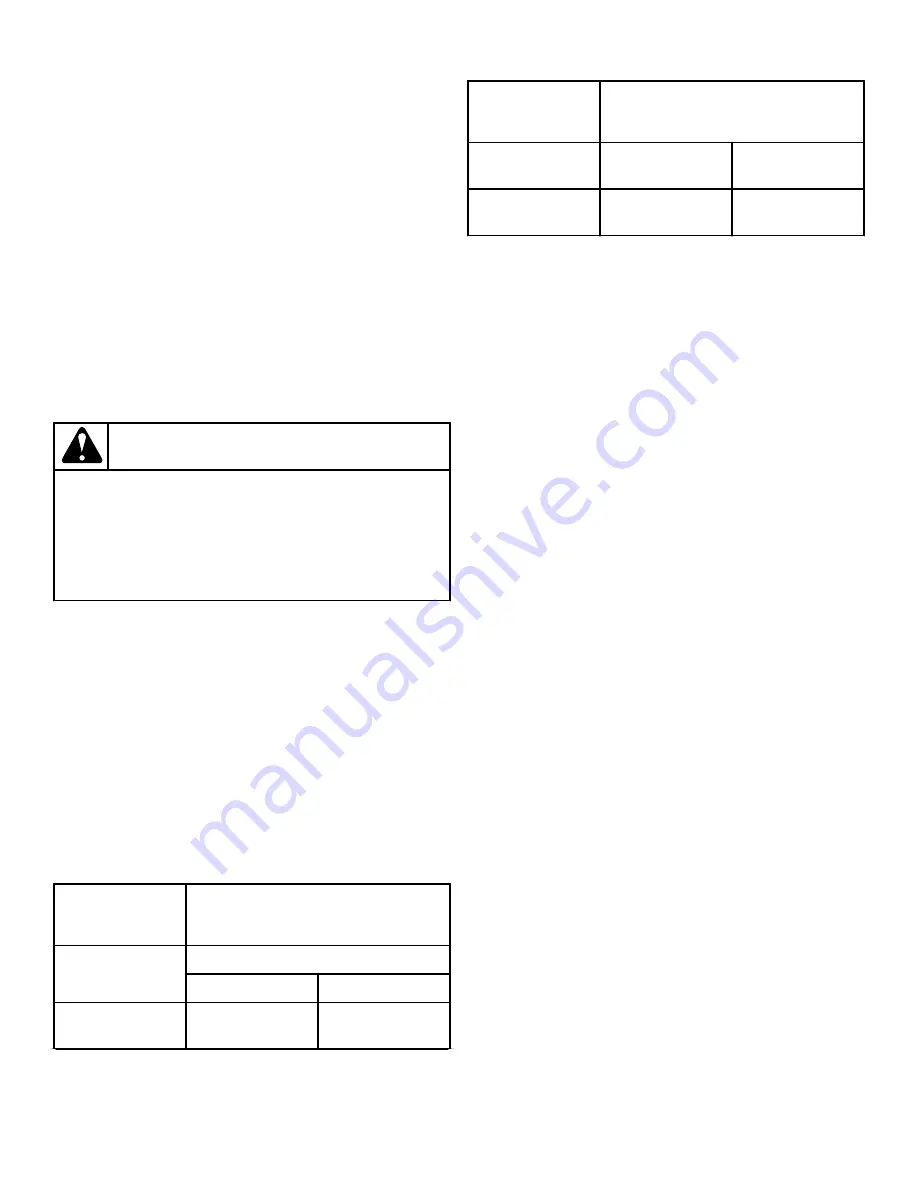

Silicon Carbide Ignition:

Coil Tolerance

Readings

Meter probes to ter-

minals:

Meter should read:

50 Hertz

60 Hertz

Holding Coil – Ter-

minals 1 & 2

1700 ± 285 Ohms

1365 ± 230 Ohms

Table 2

continues...

Coil Tolerance

Readings

Booster Coil – Ter-

minals 1 & 3

685 ± 115 Ohms

560 ± 100 Ohms

Secondary Coil –

Terminals 4 & 5

1680 ± 285 Ohms

1325 ± 230 Ohm

Table 2

Silicon Nitride Ignition:

Both coils should read between

2400-2800 Ohms.

NOTE: If meter registers any other readings than those

listed above, the respective coil(s) should be replaced.

Sensor Check (Gas Models)

1. While supporting the access panel, remove two screws from

bottom edge of access panel.

2. Gently lower the access panel to disengage locators from bot-

tom edge of front panel.

3. Close main gas shut-off valve. Refer to

.

4. Remove wires from sensor terminals.

5. Set test meter to read Ohms and put meter probes on sensor

terminals. Meter should read “zero” Ohms. If meter registers

an Ohm reading of any amount, replace sensor.

Igniter Check - Gas Models

1. While supporting the access panel, remove two screws from

bottom edge of access panel.

2. Gently lower the access panel to disengage locators from bot-

tom edge of front panel.

3. Close main gas shut-off valve. Refer to

.

4. Disconnect igniter wires at disconnect block.

5. Set test meter to read Ohms and put meter probes on terminals

of igniter wires.

6.

Silicon Carbide Igniter:

Meter should read between 45 –

200 Ohms.

Silicon Nitride Igniter:

Meter should read be-

tween 49 – 88 Ohms.

NOTE: If meter does not read appropriate Ohms, then

replace the igniter.

IMPORTANT: Always examine all wires, terminals and

connectors to be sure wiring is correct before replac-

ing any components.

Ignition Control Grounding Check -

Silicon Nitride Ignition

Test Procedures

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

61

Part No. D515519R3

Summary of Contents for BD3NGBGS303EW01

Page 2: ......