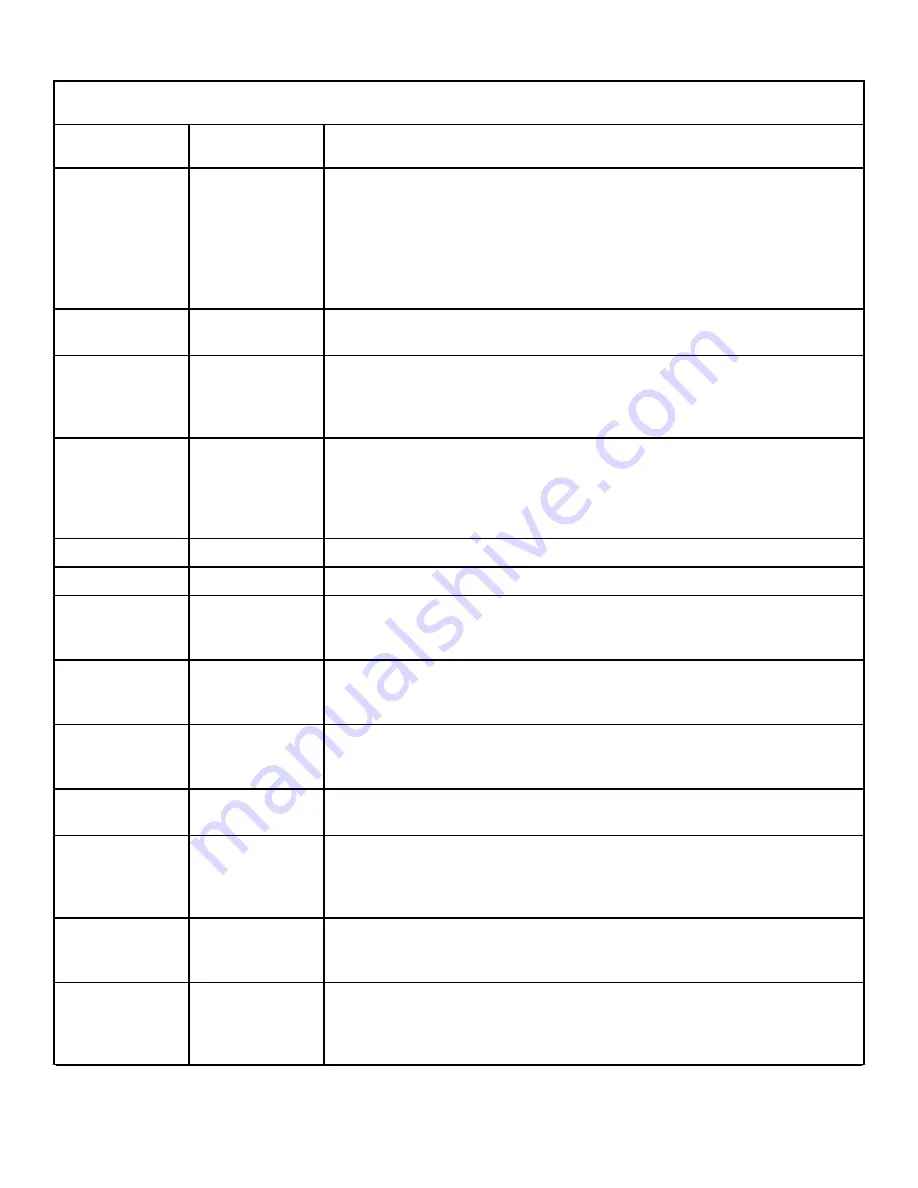

Error Codes

Display

Description

Cause/Corrective Action

E PS

Pressure Sensor Er-

ror

If the control does not detect a valid water level sensor input for thirty (30) seconds, or

if the Max (Overflow) Fill Level in the control is set to 0 while in Run Mode, Factory

Test Mode, or Overflow Mode, the control will enter Machine Error Mode. The con-

trol will first drain for thirty (30) seconds to get out any water, and unlock the door. To

clear this error one of the following must occur: the machine must be powered down,

the Clear Fatal Error Keys must be pressed, or a Clear Fatal Error Network command

must be sent.

E tr

Trim Error

The machine must be powered down, the Clear Fatal Error Keys must be pressed or a

Clear Fatal Error Network command must be send.

E bELt

Broken Belt Error

If a broken belt is ever detected by the control, the control will show error this error

code. To clear this error one of the following must occur: the machine must be powered

down, the Clear Fatal Error Keys must be pressed, or a Clear Fatal Error Network com-

mand must be sent.

E LF

Water Leak Fill Er-

ror

If the water level has raised more than an acceptable amount in a during a water leak

check, the control will save a water leak error status and will continue the machine cy-

cle. Immediately upon detecting the error the right-most decimal point will be lit. This

lit decimal point can be cleared by pressing the START keypad 3 times in a period of 5

seconds or by cycling the power to the machine.

Display is dim

Look for loose pins and damaged wires on harness from user control to drive board.

E d

Drive Board Errors

E d 10

Voltage Select Error Wrong Input Voltage seen at drive board 120V vs 240V. Dip switch 1 on FEC set

wrong, or possibly water on drive board (let drive dry out and determine cause of wa-

ter). Unpower to clear error. Replace drive board if error persists.

E d 12

Over Voltage AC-

Main Input Error

Machine voltage is too high, check supply voltage to the machine and verify that it is

within machine specifications. Unpower to clear error. Replace drive board if error per-

sists.

E d 13

Power Fail Danger-

ous Error

The Neutral Line power input to the machine was seen out of range. Unpower to clear

error. Check for damage in the power supply harness. Replace power supply harness or

drive board if error persists.

E d 21

Over Voltage DC

Bus Error

Unpower to clear error. Check voltage input to machine. If it happens only at start of

spin, replace motor. Replace drive board if error persists.

E d 22

Over Motor Tem-

perature Error

Motor temperature is detected to be too high. Check that drum spins freely when empty.

Check for overloading of machine. Check motor harness for damage. Reduce agitation

time and duty cycle ifrotate/pause times are very short and programmable. Unpower to

clear error. Replace drive board if error persists.

E d 23

Fatal IPM Over

Current Shunt Error

Check that drum and motor spins freely. Unpower to clear error. Check the motor phase

windings. Continuity should be uniform between phases L1 and L2, L2 and L3, L1 and

L3. Replace motor if not uniform. Replace drive board if error persists.

E d 24

Fatal I2T Hardware

Over Current Error

Check that drum and motor spins freely. Rotor may be locked up. Check the motor

phase windings. Continuity should be uniform between phases L1 and L2, L2 and L3,

L1 and L3. Replace motor if not uniform. Unpower to clear error. Replace drive board

if error persists.

Table continues...

Error Codes

©

Published by permission of the copyright owner -

DO NOT COPY or TRANSMIT

114

Part No. 805405ENR5

Summary of Contents for BT3JGASG403UW01

Page 2: ......