506471-01

Page 34 of 41

Issue 1034

The heating value of the gas can be obtained from the local

utility company.

For Propane Gas:

The only check for the furnace rate is to

properly adjust the manifold pressure using a manometer

and the information provided in Table 12. Typical manifold

set point for installations at altitudes from 0 to 4500 feet

above sea level is 10.0" W.C.

Temperature Rise

Check the temperature rise and, if necessary, adjust blower

speed to maintain temperature rise within the range shown

on the unit rating plate.

High Altitude

In both the United States and Canada, this furnace is

approved for operation at altitudes from 0 to 4500 feet above

sea level without any required modifications. From 4500 to

7500 feet, the gas manifold pressure needs to be adjusted

For Natural Gas:

Check the furnace rate by observing the

gas meter, when available, making sure all other gas

appliances are turned off. The test hand on the meter should

be timed for at least one revolution. Note the number of

seconds for one revolution.

according to the information shown in Table 12. To adjust

the manifold pressure, refer to previous section

Checking

and Adjusting Gas Input.

For installations above 7500

feet, call Technical Service at 1-800-515-3501 for assistance.

For installations above 4500 feet fill in the appropiate

information on the furnace label that has the words

“This

furnace was converted on . . . . . . “.

Emergency Replacement Motor Operation

If the variable speed motor needs to be replaced in an

emergency situation (such as “no heat”) and an exact

replacement motor is not immediately available, a standard

PSC motor of equivalent frame size, voltage, rotation, and

horsepower can be

temporarily

installed until the correct

replacement motor can be obtained.

Connect the desired speed tap to the “EAC” terminal and the

neutral tap to the neutral terminal on the ignition control (refer

to the furnace wiring diagram). T he ignition control will control

the motor’s operation, including a nominal 20 second “on” delay

with a call for heat and a nominal 180 second “off” delay when

the thermostat is satisfied. It will also operate the motor on a

call for cooling, with no “on” or “off” delays.

Verify that the unit is operating at the desired speed and

within the rise range as shown on the unit rating plate.

The correct replacement motor must be installed as

soon as possible to ensure continued satisfactory

operation of the furnace.

x

3600 x

= Cubic Feet Per Revolution

BTU/HR

INPUT

# Seconds Per Revolution

Heating

Value

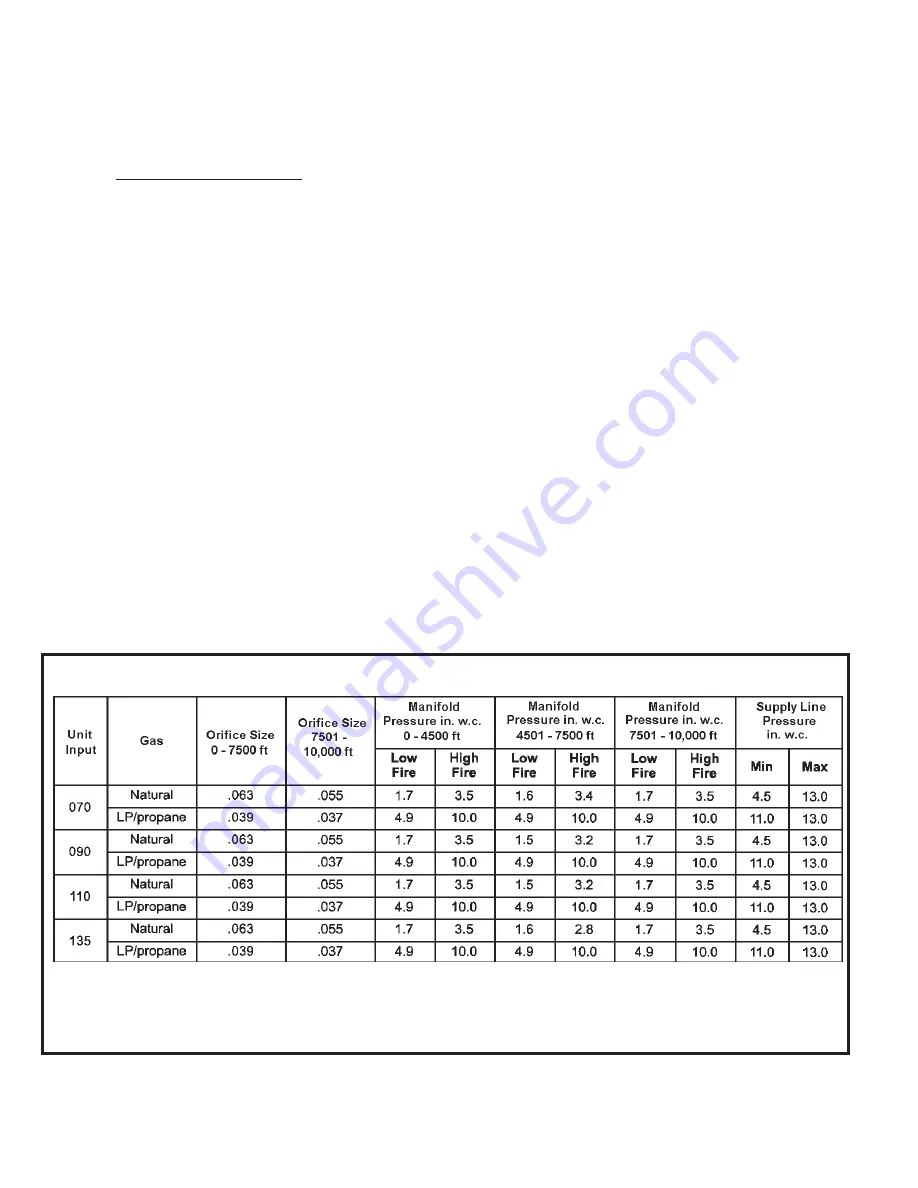

MANIFOLD PRESSURE SETTINGS

Table 12

* Consult local utility for actual heating value.

Furnace input = Input Factor x Nameplate Input

NOTE:

A natural to LP/Propane gas changeover kit is necessary to convert this unit. Refer to the changeover kit installation instruction for the

conversion procedure.

Summary of Contents for 80G1UH2V

Page 29: ...506471 01 Page 29 of 41 Issue 1034 ADJUSTING AIRFLOW Table 11 ...

Page 39: ...506471 01 Page 39 of 41 Issue 1034 Typical Field Wiring Diagram Figure 41 ...

Page 40: ...506471 01 Page 40 of 41 Issue 1034 START UP PERFORMANCE CHECK LIST UNIT SET UP ...

Page 41: ...506471 01 Page 41 of 41 Issue 1034 UNIT OPERATION ...