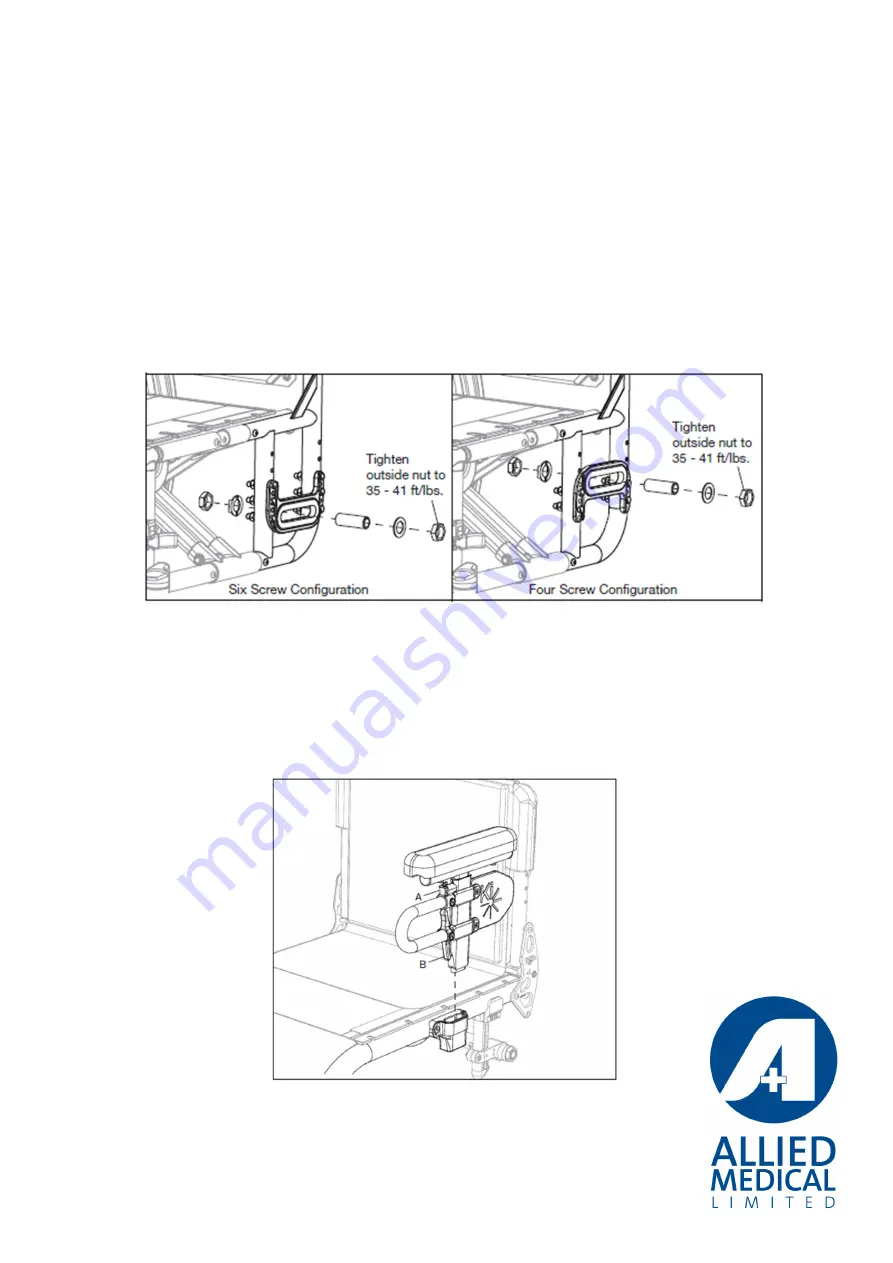

Wheelbase Width Adjustment

Adjusting the wheelbase width allows the user the option to move the wheels closer or further

away from the hips. It also compensates for camber adjustment and gives the proper wheel

spacing to maximise pushing efficiency.

To adjust:

1. Loosen the nut on the outside of the axle with a 24mm spanner, then turn the threaded axle

sleeve in or out to desired width.

2. Re-tighten the nut

3. Repeat on opposite side

Note: Check that there is sufficient clearance so that the wheel does not rub on the side

guards, arm supports or wheel locks.

Adjusting T-Arm Height

1. Install T-Arm assembly into the receiver. Ensure the latch (B) “clicks” into place.

2. Adjust the height by loosening the height lever (A) and sliding the T-Arm post up or down.

3. Repeat steps on opposite side.