General

1 - 6

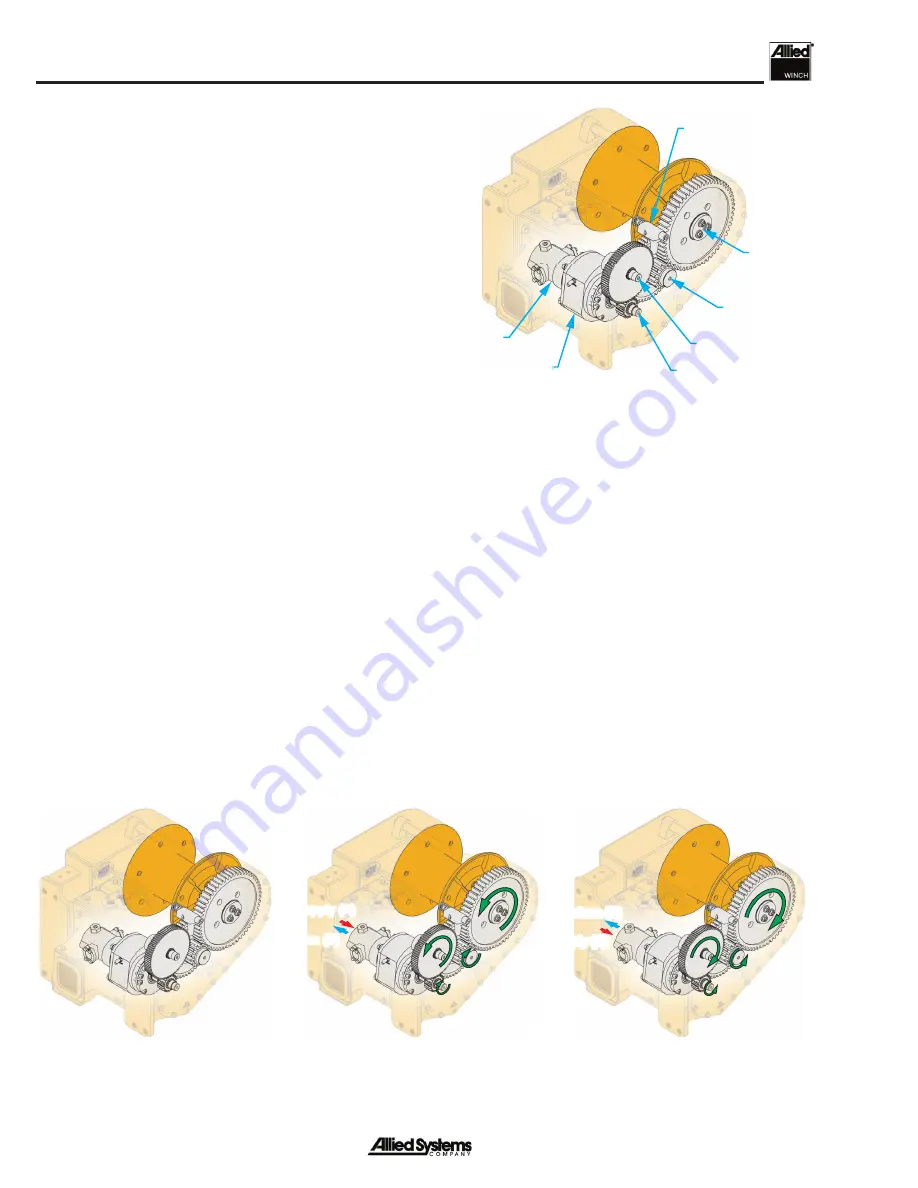

Figure 1-9 Rotation Torque Transfer

Figure 1-8 Gear Train

Motor Shaft

Idler Shaft

Intermediate

Shaft

Drum

Shaft

Hydraulic

Motor

Brake

Freespool Fork

BRAKE-ON

LINE-IN

LINE-OUT

Oil Supply (A)

Oil Return (B)

Oil Return (A)

Oil Supply (B)

Gear Train (See Fig. 1-8)

The tractor pump or designated winch pump drives the

hydraulic motor with hydraulic oil supply. The amount of

pressure in the motor is dependent on the size of the load.

The motor shaft rotates to give

LINE-IN

or

LINE-OUT

.

Return oil is directed back to the tractor reservoir in open

loop systems and back to the pump in hydrostatic closed

loop systems. The motor is attached to a spring applied

multi-disc brake that holds the winch drum in a fi xed posi-

tion. When oil is supplied to the hydraulic motor, the brake

is simultaneously released with pilot control pressure.

The hydraulic motor can operate at half displacement

when the operator selects the

HI-SPEED

switch. At half

displacement the gear train rotates at roughly twice the

speed.

An intermediate gear assembly gives further gear reduc-

tion to increase torque at the winch drum. A spring-loaded

dental clutch with splines engages the drum pinion gear

and the intermediate gear. The operator can disengage

the dental clutch with an electric switch to activate the

FREESPOOL

feature.

A drum gear engages the drum pinion gear and is con-

nected to the drum adapter (which connects the drum to

the drum gear). When power is applied to the gear train,

the drum will rotate in the forward or reverse direction. The

other side of the drum runs on roller bearings held by the

drum shaft. The drum shaft is connected to the winch case.

Summary of Contents for H5C Series

Page 8: ...vi Notes...

Page 48: ...General 1 40 Notes...

Page 59: ...Troubleshooting 2 6 Notes...

Page 77: ...Service 3 18 Notes...

Page 86: ...Section 4 4 9 Intentionally Blank...

Page 104: ...Section 4 4 27 Intentionally Blank...

Page 108: ......