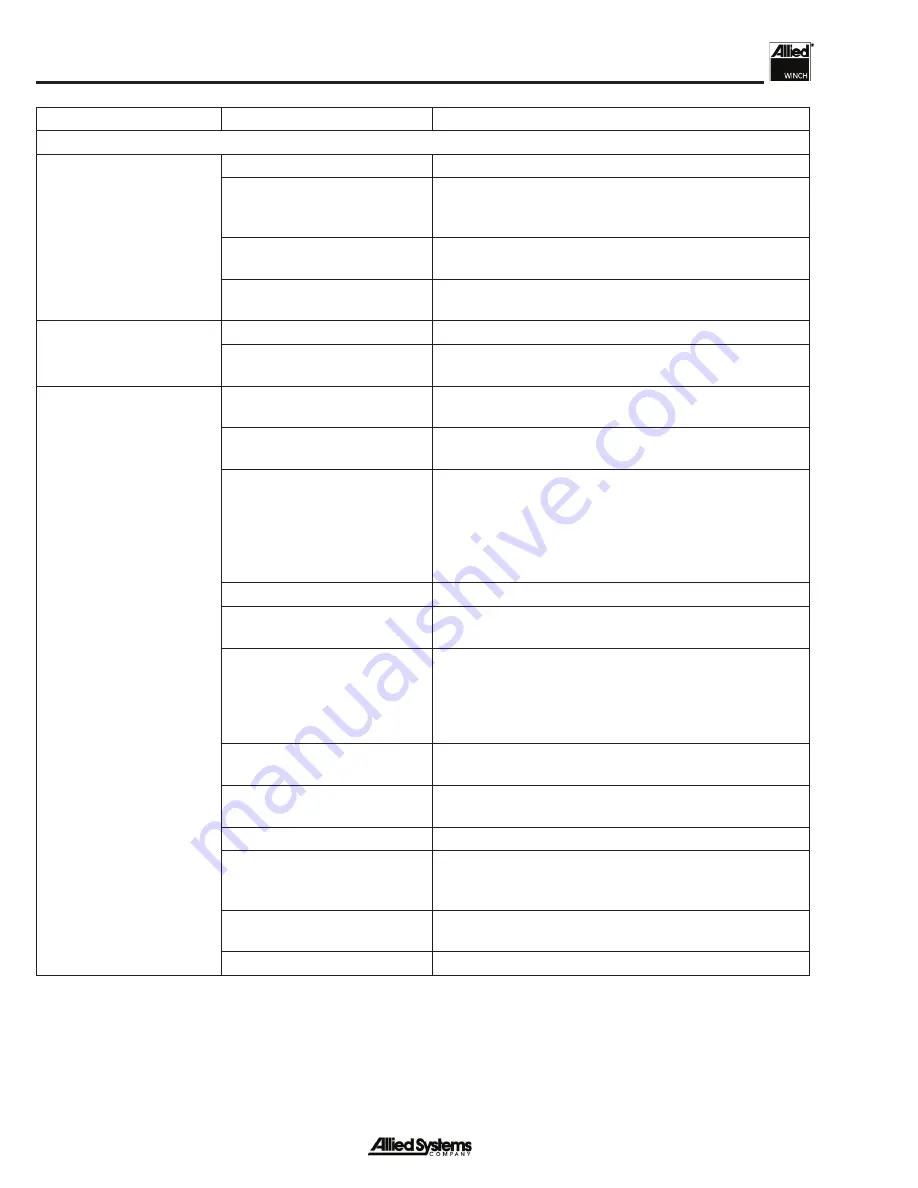

Troubleshooting

2 - 2

PROBLEM

POSSIBLE CAUSE

CORRECTION ACTION

Winch Operates But Exhibits The Following Problems

Winch operates in

LINE-

IN

only.

Brake shuttle stuck.

Check for debris.

Counterbalance valve pilot

signal blocked or connected

to drain.

Check for plugged control manifold passage or missing

manifold plug.

Counterbalance valve

damaged or set incorrectly.

Adjust or replace counterbalance valve.

Malfunction in the ripper

control circuit.

Troubleshoot circuit per tractor service manual.

Winch operates in

LINE-

OUT

only.

Brake shuttle stuck.

Check for debris.

Malfunction in the ripper

control circuit.

Troubleshoot circuit per tractor service manual.

Winch will not generate

suffi cient line pull.

Tractor implement pump relief

set too low.

Check tractor hydraulic system settings.

Worn or damaged components

in the gear train.

Visually Inspect to identify damaged components. Repair

and replace as necessary.

Brake not releasing due to

insuffi cient brake release pres-

sure or leak in brake.

Check that brake release pilot pressure is more than 200

psi in

LINE-IN

and

LINE-OUT

functions. If pilot pressure

is too low, check for leaks, faulty control lever, or insuf-

fi cient pilot supply pressure. See Step By Step Pump

and Controller Troubleshooting section in this chapter. If

brake is leaking, repair as needed.

Brake shuttle valve stuck.

Clean or replace as necessary.

Leak in hydraulic system other

than brake assembly.

Plug brake line and check that pressure at motor ports

A & B (See Hydraulic System Pressure Check Tables).

Leak in motor speed spool re-

lief cartridge (

HI-SPEED

only).

Check that the pressures at motor test ports A & B are

suffi cient for operating the winch in

LINE-IN/OUT

with the

brake line plugged. If the pressure is low and registered

simultaneously at A and B, leakage is occurring past the

relief valve. Remove and repair the valve.

Clogged fi lter.

Tractor fi lter indicator light will illuminate if fi lter is clogged.

Replace fi lter. Refer to tractor specifi cations.

Wrong oil.

Use correct oil grade; refer to tractor oil specifi cations.

Low oil level in reservoir.

Add oil; refer to tractor oil specifi cations.

Damaged freespool compo-

nents may be causing winch

to be stuck in

FREESPOOL

.

Inspect freespool shaft for wear or damage, repair or

replace as necessary.

Drag brake piston stuck.

Remove drag brake cover to determine if piston is stuck

and not releasing the drag brake clutch.

Motor damaged.

Repair or replace motor.

Figure 2-1 Mechanical/Hydraulic Troubleshooting Chart - 2

Summary of Contents for H5C Series

Page 8: ...vi Notes...

Page 48: ...General 1 40 Notes...

Page 59: ...Troubleshooting 2 6 Notes...

Page 77: ...Service 3 18 Notes...

Page 86: ...Section 4 4 9 Intentionally Blank...

Page 104: ...Section 4 4 27 Intentionally Blank...

Page 108: ......