Section 4

4 - 19

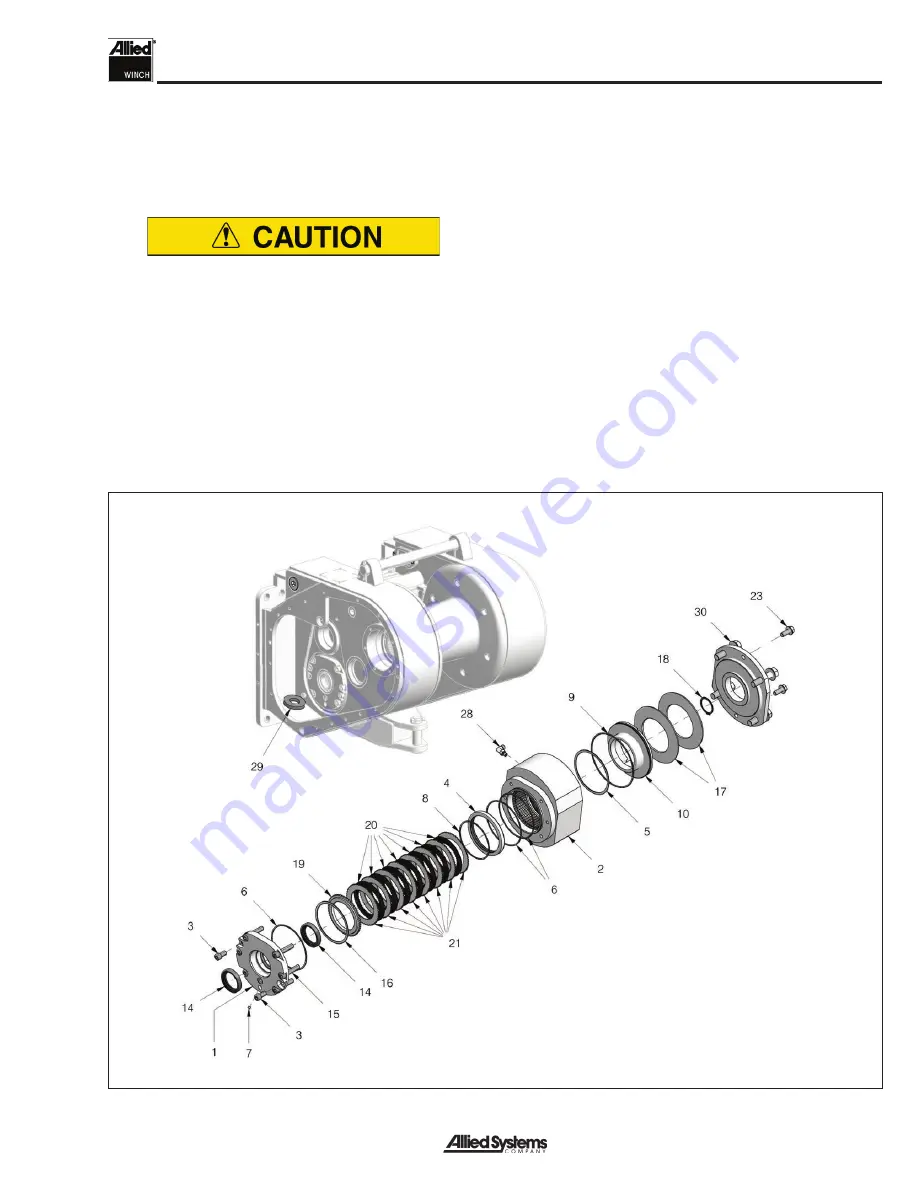

Figure 4-5 Brake Assembly

Brake Assembly

1.

Clean all parts thoroughly.

2.

Install brake discs starting with a separator disc, and

then alternate with a friction disc. You should start and

end with a separator disc.

The brake is a dry multi-disc design. Do not

get any oil on the friction discs. If the friction

discs are contaminated with oil, the brake will

greatly reduce holding power, and the brake

discs must be replaced.

3.

Install new o-rings on the piston and lightly coat with

hydraulic oil. Do not get any oil on brake discs, see

Caution above.

4.

Install brake springs. Make sure that they are stacked

together like dinner plates with the outer rim towards

you.

5.

Install mounting plate. Hand tighten all four cap-

screws evenly. Then tighten one turn at a time in

rotation until mounting plate is fl at against the brake

housing. Torque capscrews to 285 lbs ft.

6.

Reinstall the motor, replace o-rings on motor pilot.

Torque 1/2” capscrews to 80 lbs ft. (3/4” capscrews

to 285 lbs ft.).

7.

Connect hydraulic hard lines and hose. Replace any

o-rings that were disturbed with new.

8.

Install side cover. Once winch is reinstalled on the

tractor, check for leaks, pressure settings, and proper

operation.

1.

Brake Mounting Plate

2. Brake

Housing

3. Capscrew

4. Sleeve

5. Snap

Ring

6. O-Ring

7. Pipe

Plug

8. O-Ring

9. O-Ring

10. Brake

Piston

11. Ball

Bearing

14. Rotary

Seal

15. Capscrew

16. Snap

Ring

17. Belleville

Spring

18. Snap Ring, External

19. Pressure

Plate

20. Friction

Disc

21. Separator

Plate

23. Flangescrew

28. Fitting

29. Magnet

30. Capscrew

Note:

Minimum pack height of

service items #20 and #21

is 1.397”.

- ID Towards

Piston (#10)

Summary of Contents for H5C Series

Page 8: ...vi Notes...

Page 48: ...General 1 40 Notes...

Page 59: ...Troubleshooting 2 6 Notes...

Page 77: ...Service 3 18 Notes...

Page 86: ...Section 4 4 9 Intentionally Blank...

Page 104: ...Section 4 4 27 Intentionally Blank...

Page 108: ......