Repairs

4 - 24

Winch Assembly

All components should be inspected for wear or damage

as they are removed. Refer to Figure 4-8, Visual Inspection.

All seals that were removed should be replaced during

assembly. Carefully inspect all bearings that have been

removed. Used bearings often appear satisfactory, but

may fail when placed under a load. When in doubt, it is

recommended to install a new bearing. Any component

that indicates excessive wear or damage should be

replaced. The following reassembly and installation

sequence assumes a complete winch overhaul.

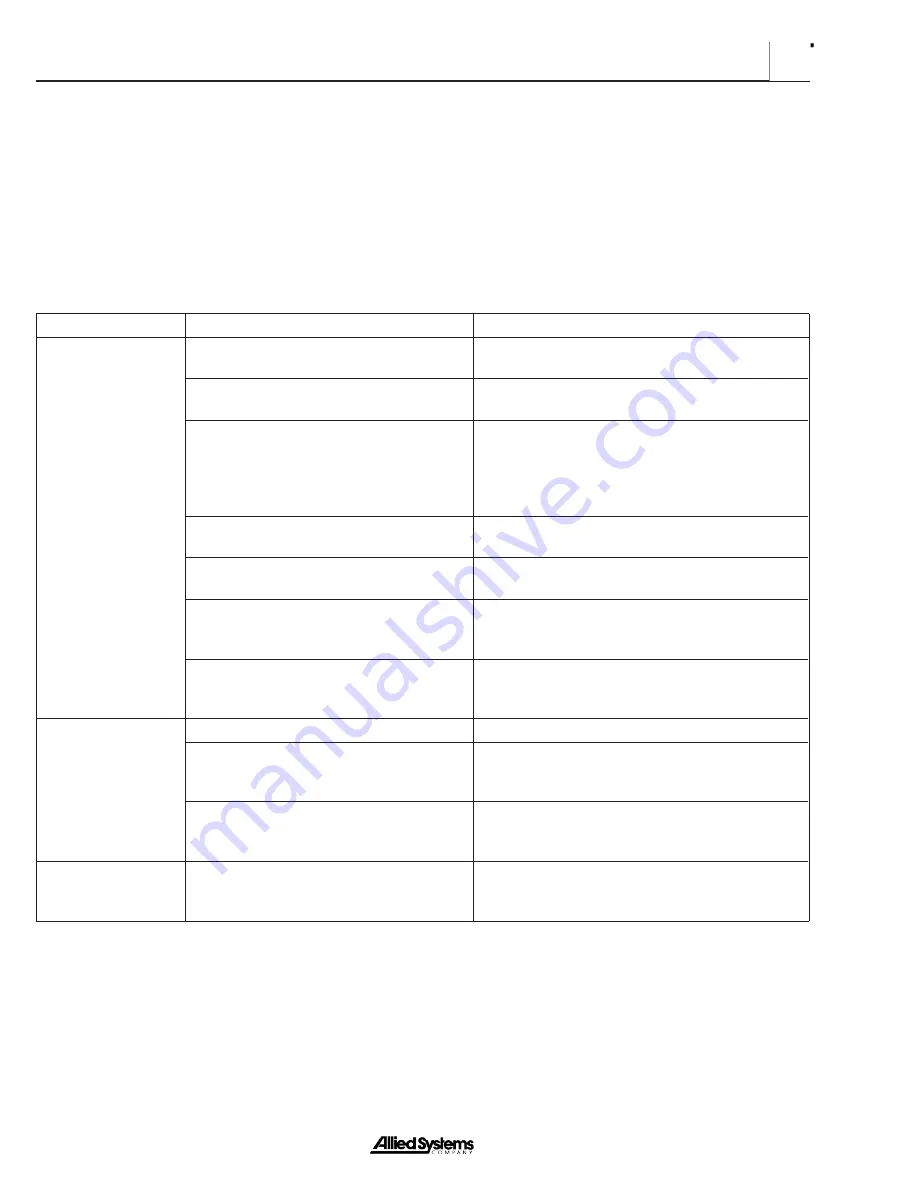

Figure 4-8 Visual Inspection -1

ITEM

INSPECTION REQUIREMENTS

CORRECTIVE ACTION

Brake Assembly

Check for cracked or broken belleville/coil

springs.

Replace springs if cracked or broken.

Inspect housing and covers for leakage or

damage.

Replace component if sealing surfaces or splines

are damaged.

Check the rotor discs for wear, distortion,

or damage. The discs should be free of

hydraulic oil.

Replace the rotor discs if the wear grooves are

worn away, the discs are burned, damaged,

warped, or exposed to oil. Brake cleaner may

be used to clean dust from the discs but will not

remove impregnated oil.

Check the brake/motor shaft seals for

leakage into the brake housing.

Replace damaged seals.

Inspect the brake/motor shaft for wear or

damage.

Replace a damaged shaft.

Check that the stator discs are flat, free of

large blue areas (caused by overheating)

or damaged surfaces.

Replace damaged stator discs.

Inspect the piston for damage. Make sure

the seal groove and sealing surfaces are

in good condition.

Replace a damaged piston. Always replace the

piston seals when the brake is repaired.

Planetary Speed

Reducer

Check the housing for leakage or damage. Repair or replace assembly.

Check output shaft bearing end play.

End play is 0.000-0.006”. End play is adjusted

using the appropriate thickness retaining ring.

See parts manual.

Inspect sun gear and carrier assembly for

damage or wear. Sun gear should spin

freely in carrier assembly.

Replace assembly.

Winch Motor

Inspect motor shaft seal for wear or

damage.

Note: A leaky motor shaft seal will contaminate

the brake with oil and the brake will likely require

service. Replace seal.

- Winch Assembly

Summary of Contents for H6H

Page 3: ......

Page 9: ...vi Notes...

Page 49: ...General 1 40 Notes...

Page 65: ...General 1 56 Notes Notes...

Page 71: ...Troubleshooting 2 6 Notes...

Page 78: ...Section 3 3 7 Notes...

Page 79: ...Service 3 8 Notes...

Page 84: ...Section 4 4 5 Intentionally Blank...

Page 92: ...Section 4 4 13 7 Remove the counterbalance relief manifold...

Page 96: ...Section 4 4 17 Intentionally Blank...

Page 98: ...Section 4 4 19 7 Separate the clutch hub and the pressure plate CLUTCH HUB PRESSURE PLATE...

Page 102: ...Section 4 4 23 Intentionally Blank...

Page 112: ...Section 4 4 33 Intentionally Blank...

Page 126: ...Section 4 4 47 Intentionally Blank...

Page 132: ...Section 4 4 53 Notes...