Repairs

4 - 36

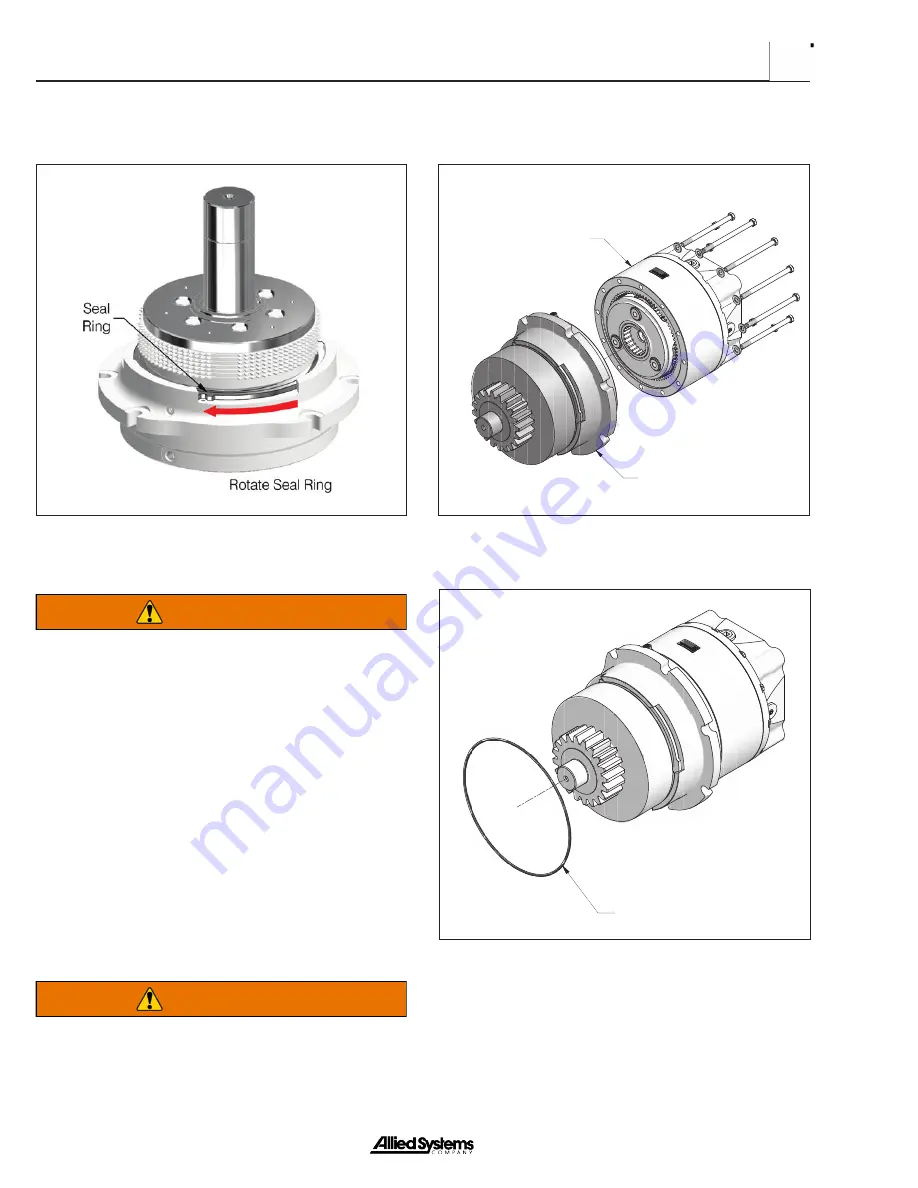

6. Rotate seal ring clockwise with brass drift and

hammer until lock bolt notch aligns with bolt hole.

7.

Testing clutch

WARNING

Wear safety glasses whenever working

around pressurized hydraulics.

7.1 Apply hydraulic pressure to port on clutch housing;

7.2 Steadily increase pressure. Gear should begin to

rotate by hand at about 360 psi;

7.3 Increase pressure further, clutch should reach full

release at 420 psi;

7.4 Increase pressure to 700 psi MAX and check for

leaks.

8. While clutch is released, friction disks can be aligned

by carefully assembling spider gear and aligning

splines.

WARNING

Use caution to prevent pinching fingers

during spider installation - splines are sharp

and can cut.

9.

Install clutch housing assembly into reducer.

PLANETARY REDUCER (REF)

CLUTCH HOUSING

10. Install new O-ring on clutch housing.

O-RING

- Motor Shaft Assembly & Installation

Summary of Contents for H6H

Page 3: ......

Page 9: ...vi Notes...

Page 49: ...General 1 40 Notes...

Page 65: ...General 1 56 Notes Notes...

Page 71: ...Troubleshooting 2 6 Notes...

Page 78: ...Section 3 3 7 Notes...

Page 79: ...Service 3 8 Notes...

Page 84: ...Section 4 4 5 Intentionally Blank...

Page 92: ...Section 4 4 13 7 Remove the counterbalance relief manifold...

Page 96: ...Section 4 4 17 Intentionally Blank...

Page 98: ...Section 4 4 19 7 Separate the clutch hub and the pressure plate CLUTCH HUB PRESSURE PLATE...

Page 102: ...Section 4 4 23 Intentionally Blank...

Page 112: ...Section 4 4 33 Intentionally Blank...

Page 126: ...Section 4 4 47 Intentionally Blank...

Page 132: ...Section 4 4 53 Notes...