Section 2

2 - 3

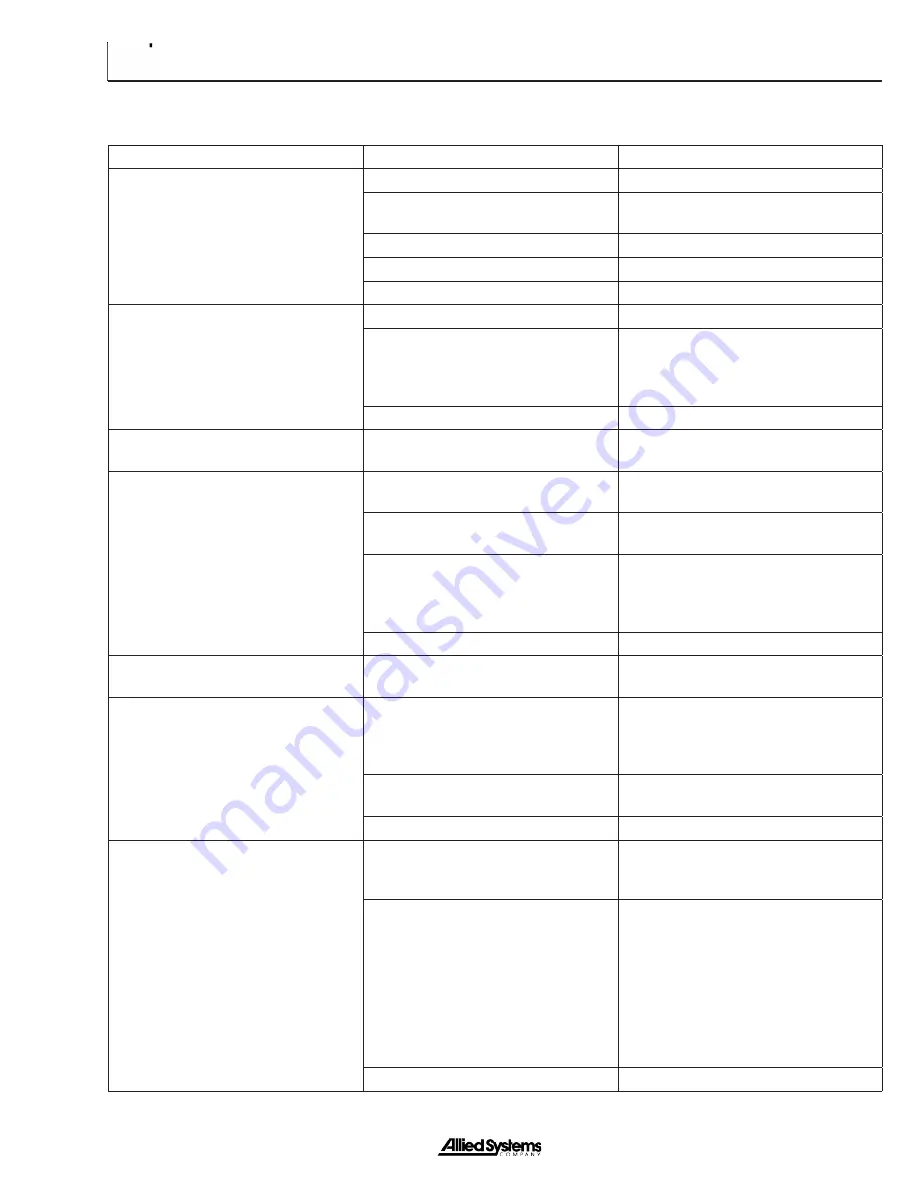

Figure 2-1 Troubleshooting Analysis Check Chart -1

PROBLEM

POSSIBLE CAUSE

CORRECTION

Winch gets very hot

Low oil level.

Add oil; refer to tractor oil specifications.

Improper oil viscosity.

Use correct oil grade; refer to tractor oil

specifications.

Winch coated with dirt.

Clean winch.

Clogged filter or strainer.

Replace tractor filter.

Clogged cooler.

Clean cooler.

Operation is rough

Low oil level.

Add oil; refer to tractor oil specifications.

Low pilot pressure.

Normal pressure is above 500 psi. Look

for leaks in hydraulic system. If none

are found, see Pilot Supply Reducing

Valve Adjustment.

Wire rope jumps layers on drum.

Spool cable more evenly.

Winch chatters in

LINE-OUT

operation

(lightly loaded or no load)

Incorrect accumulator charge.

Check charge pressure.

Operation is noisy

Incorrect oil used.

Drain reservoir and re-fill with correct

oil; refer to tractor oil specifications.

Air in the hydraulic oil (indicated by

foaming or milky-colored oil).

Replace oil and inspect for leaks and

other sources of air induction.

Motor damaged.

Some noise is normal. However,

excessive clattering could indicate

damage. Inspect pump and motor

thoroughly.

Gear or bearing damage.

Visually inspect & repair as needed.

Winch chatters in

LINE-OUT

operation

(lightly loaded or no load)

Incorrect accumulator charge.

Check charge pressure.

Drum continues to rotate after lever is

returned to

BRAKE-ON

Direction spool not shifting to centered

position.

Direction spool sticking. Clean or

replace.

Control lever valve plunger sticking.

Repair.

Brake not engaged or worn.

Brake release pressure is not venting.

Check for trapped pressure.

Counterbalance valve stuck open.

Repair or replace valve.

Winch will not generate sufficient line

pull or does not line in or line out

(Continued on next page)

Worn or damaged components in the

gear train.

Visually Inspect to identify damaged

components. Repair and replace as

necessary.

Brake not releasing due to insufficient

brake release pressure or leak in

brake.

Check that brake release pilot pressure

is more than 300 psi in

LINE-IN

and

LINE-OUT

functions. If pilot pressure

is too low, check for leaks, faulty

control lever, or insufficient pilot supply

pressure. See Step By Step Pump and

Controller Troubleshooting section in

this chapter. If brake is leaking, repair

as needed.

Brake shuttle valve stuck.

Clean or replace as necessary.

Troubleshooting Analysis Check Chart

Summary of Contents for H6H

Page 3: ......

Page 9: ...vi Notes...

Page 49: ...General 1 40 Notes...

Page 65: ...General 1 56 Notes Notes...

Page 71: ...Troubleshooting 2 6 Notes...

Page 78: ...Section 3 3 7 Notes...

Page 79: ...Service 3 8 Notes...

Page 84: ...Section 4 4 5 Intentionally Blank...

Page 92: ...Section 4 4 13 7 Remove the counterbalance relief manifold...

Page 96: ...Section 4 4 17 Intentionally Blank...

Page 98: ...Section 4 4 19 7 Separate the clutch hub and the pressure plate CLUTCH HUB PRESSURE PLATE...

Page 102: ...Section 4 4 23 Intentionally Blank...

Page 112: ...Section 4 4 33 Intentionally Blank...

Page 126: ...Section 4 4 47 Intentionally Blank...

Page 132: ...Section 4 4 53 Notes...