Service

3 - 2

Checks Before Operation

Check that the wire rope and hook are not worn or

damaged. Check that the periodic inspection and

maintenance have been done at the recommended

operating hours. See the Maintenance Schedule.

Checks During Operation

The Troubleshooting Charts in Section 2 can be used

by the operator to identify a problem with the winch

operation. A trained service person is needed for additional

troubleshooting and repair that requires disassembly of

parts of the winch.

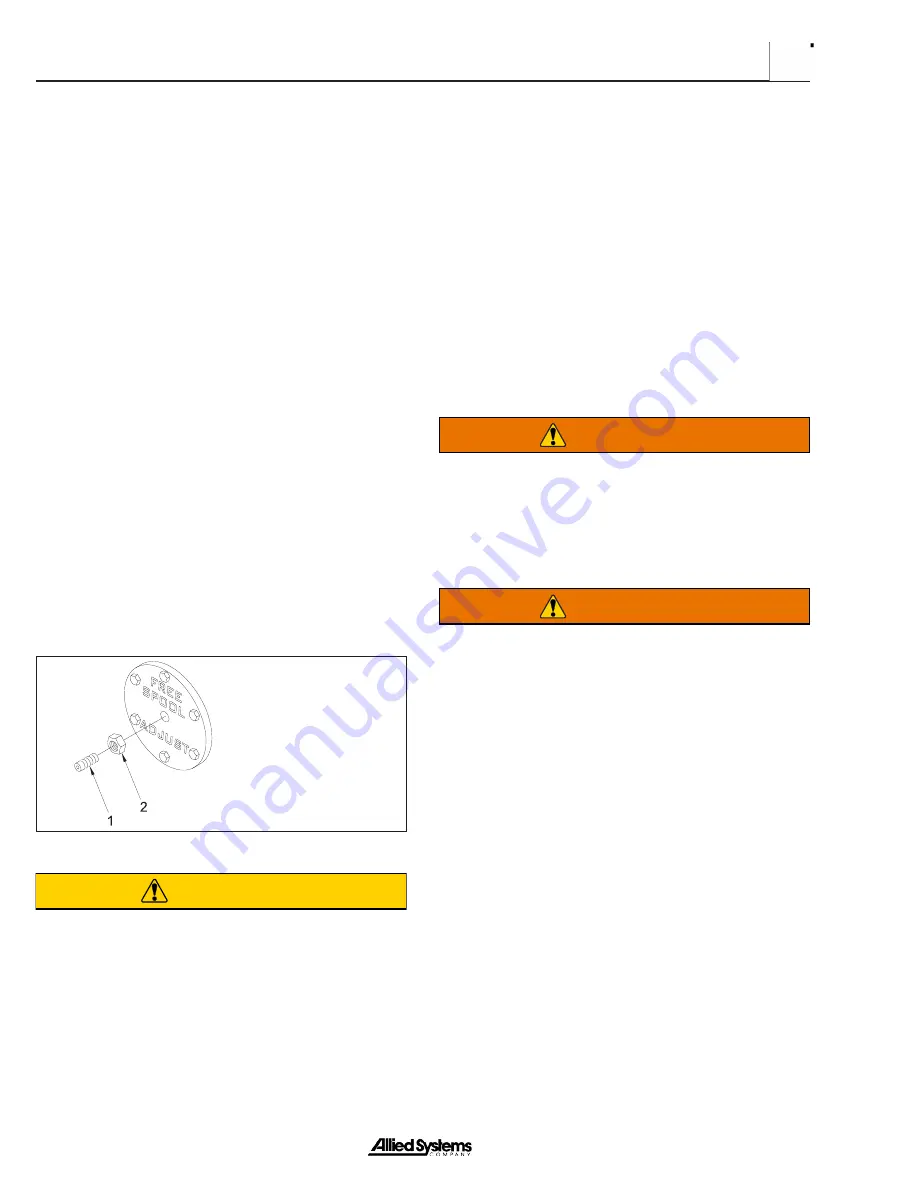

FREESPOOL Drag Adjustment (Fig. 3-3)

The preload on the bearings of the intermediate shaft

controls the resistance to rotation of the drum during

FREESPOOL

operation. The resistance to rotation is

correct when the drum can be rotated by hand, but will

not rotate more than one-half revolution after the hand

is removed.

An adjusting setscrew is located in the center of the cover

for the intermediate shaft. This screw can be tightened or

loosened to adjust the preload on the intermediate shaft.

The jam nut will maintain the

FREESPOOL

setting. This

adjustment is normally only necessary if the winch has

had an overhaul.

the housing with a hammer to make sure

the bearing is sliding. Check resistance to

rotation after each adjustment.

Hydraulic System Pressure Checks

The hydraulic oil and filter(s) should be maintained as

indicated in the tractor Service Manual. If any problems

are found, they should be corrected before operating the

winch.

Preparation

1.

These tests should be performed with a bare drum

(no wire rope) since the drum will rotate during the

tests.

WARNING

Tractor engine must be shut OFF before

disconnecting drum wire rope. Be careful

when you remove the wire rope from the

drum. The end of the wire rope can move

like a compressed spring, causing an injury

when the ferrule is released from the drum.

WARNING

Always wear gloves when handling wire

ropes.

2.

Start the engine and place the winch in

LINE-OUT

to raise the oil temperature. Another way to elevate

the reservoir temperature is to hold the tractor blade

over relief. The oil temperature in the winch or tractor

reservoir must be at least 70°F (20°C).

3. Remove any dirt from the left side of the winch.

Remove control valve access plate.

4.

Stabilize engine speed at idle RPM for all tests.

5. Leave test plugs securely installed unless testing

that port.

6. After completing all pressure checks and making

the necessary adjustments ensure that all plugs and

hoses are securely installed.

7.

Install side covers and tighten capscrews.

Pressure gauges

Six calibrated pressure test gauges are required to

perform the hydraulic pressure checks: four 1000 psi

Figure 3-3 FREESPOOL Adjustments

1.

Adjusting Nut

2.

Jam Nut

CAUTION

Setting the preload on the intermediate shaft

too tight will cause bearing overload. Setting

the preload too loose will allow shaft to not

be parallel. Extreme care must be used when

adjusting FREESPOOL drag. Determine

the correct preload by starting with the

preload too loose, and gradually increase

the preload until the correct resistance to

rotation is achieved. Increase the preload by

turning the adjusting screw by a maximum

of 1/6 rotation (60 degrees), and striking

Summary of Contents for H6H

Page 3: ......

Page 9: ...vi Notes...

Page 49: ...General 1 40 Notes...

Page 65: ...General 1 56 Notes Notes...

Page 71: ...Troubleshooting 2 6 Notes...

Page 78: ...Section 3 3 7 Notes...

Page 79: ...Service 3 8 Notes...

Page 84: ...Section 4 4 5 Intentionally Blank...

Page 92: ...Section 4 4 13 7 Remove the counterbalance relief manifold...

Page 96: ...Section 4 4 17 Intentionally Blank...

Page 98: ...Section 4 4 19 7 Separate the clutch hub and the pressure plate CLUTCH HUB PRESSURE PLATE...

Page 102: ...Section 4 4 23 Intentionally Blank...

Page 112: ...Section 4 4 33 Intentionally Blank...

Page 126: ...Section 4 4 47 Intentionally Blank...

Page 132: ...Section 4 4 53 Notes...