18

45-034, REV. 5/18

7. To decrease camber negatively, add one or more

spacer(s) between the pad and the upper platen

support.

8. Use existing capscrews only if one spacer is used. If

two or three spacers are used use P/N Y96G-0820

capscrew.

9. As the clamp arms and slides wear it may be neces-

sary to increase the positive camber.

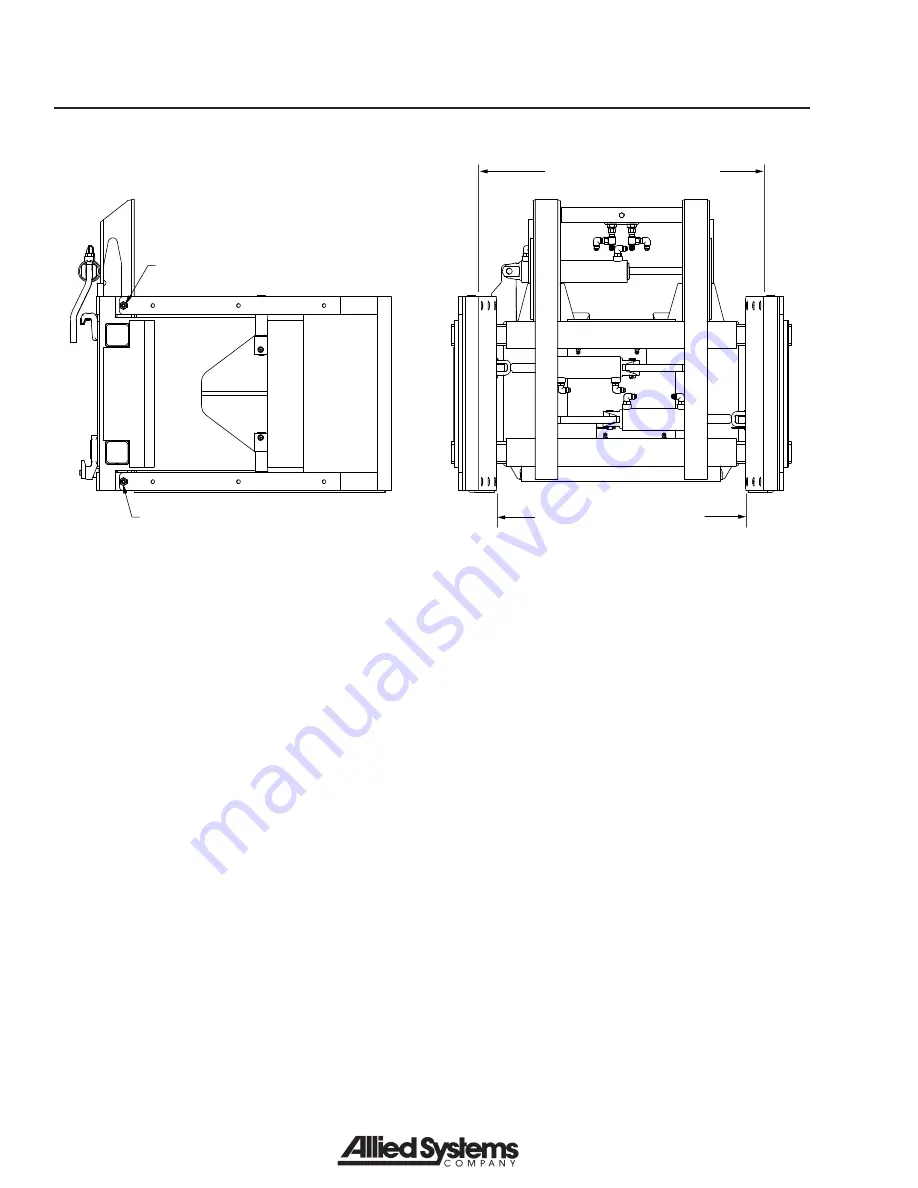

5.12 Toe Adjustment

1. The term toe adjustment refers to adjusting the

difference in the distances between the front edge

and the rear edge of the contact pads.

2. Toe out, the preferred configuration, means that the

front edges are farther apart than the rear edges.

3. Toe in means that the front edges are closer

together than the rear edges.

4. To adjust the toe out, first loosen the lock nuts and

then screw the adjustment screws out (counter-

clockwise) for greater toe out, in for less. Be sure

to adjust both the top and bottom adjustment screws

found on each platen support. (Figure 5-9)

5.13 Rotating Contact Pads

1. As the contact pads wear it may be necessary to

rotate or replace them. Pad surfaces may wear

uneven, more or less, depending on the distribu-

tion of weight in the loads.

2. Before rotating, check flatness and deflection of the

pad. The pads surface flatness should not vary more

than 1/8 inch. The horizontal and vertical deflection

of the pad should not be more than 1/4 inch.

3. Pads can be rotated left to right.

Adjustment Screw

Adjustment Screw

Front Edge/Toe Out

Rear Edge/Toe Out

Figure 5-9, Camber and Toe Adjustment