6

45-034, REV. 5/18

•

Modifications or additions that affect capacity or safe

operation must have prior written approval from the

forklift truck manufacturer. Capacity, operation, and

maintenance instruction plates, tags, or decals shall

be changed accordingly.

•

Never use free rigging for a below-the-forks lift. It

could affect the capacity and safe operation of a lift

truck.

3.6 Personnel Safety

•

When removing or installing dismountable attach-

ments always keep hands and feet free from

dangerous positions or pinch points. Never leave a

dismounted attachment in a dangerous position.

•

Keep hands, feet, long hair and clothing away from

power-driven parts. Do not wear loose fitting clothing

or jewelry while performing maintenance and lubrica-

tion in these areas.

•

Never jump on or off the machine.

•

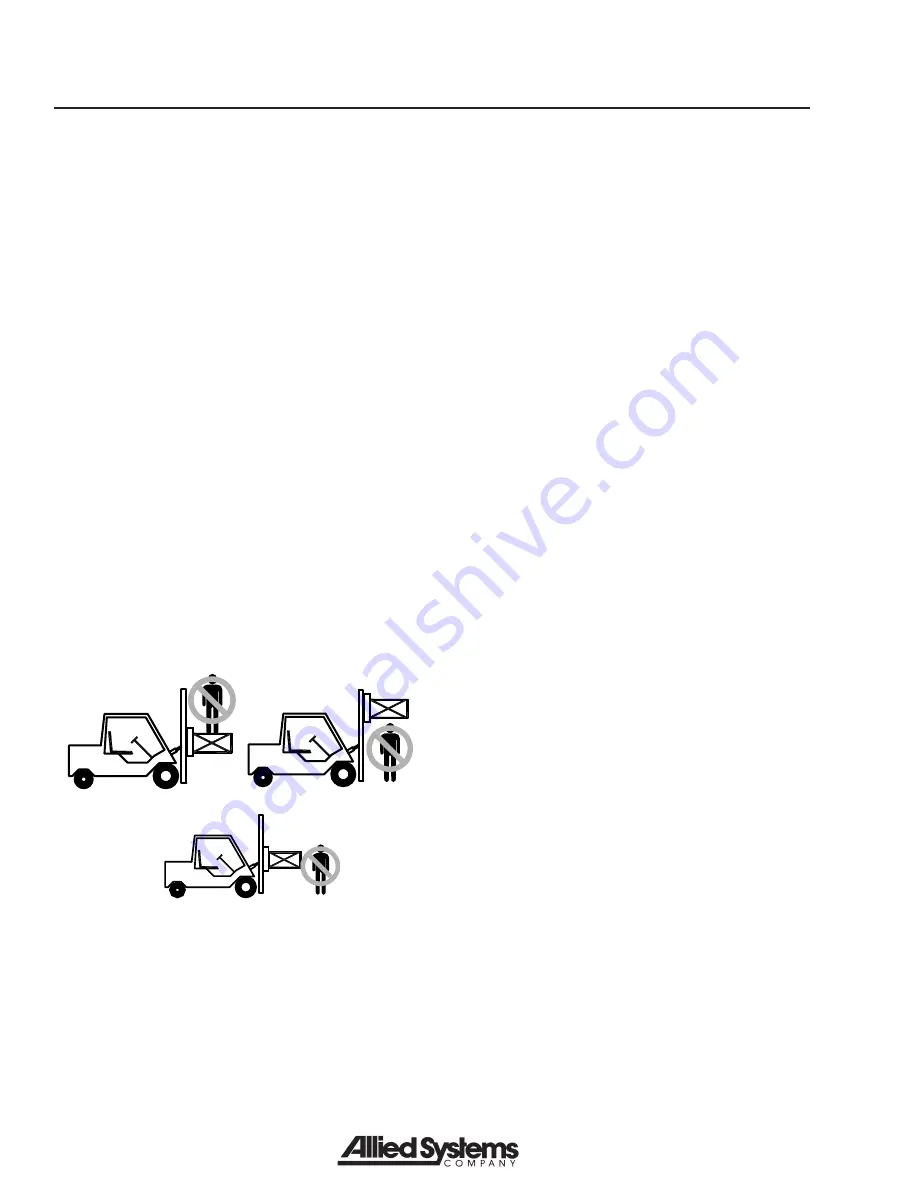

Never stand on top of material being raised, lowered,

or transported. (Figure 3-1)

Figure 3-1 Figure 3-2

Figure 3-3

•

Never use the attachment or its load to support a

man-carrying device.

•

Never allow anyone under a load or under the

carriage. (Figure 3-2)

•

Never stand in front of or beside an attachment

that is being operated. Never allow another person

to approach an attachment that is being operated.

(Figure 3-3)

•

Never leave an attachment or load in an elevated

position.

•

Never reach through the mast of the truck. Keep all

parts of the body within the driver’s compartment.

•

Always operate an attachment from the operator’s

seat, never while standing next to the lift truck.

•

Do not allow riders on the truck at any time.

•

Always use reverse when carrying a load that

impedes full vision. Watch for pedestrians when

transporting.

•

Always use personal protective equipment (PPE)

appropriate to the situation.

3.7 Pre-start Checks

•

Check your equipment before you operate it. If

anything looks wrong, unusual or different, report it

before using the attachment.

•

Do not operate this machine if you know of malfunc-

tions, missing parts, and/or mis-adjustments. These

situations can cause or contribute to an accident or

damage to the machine. Stop the machine immedi-

ately if problems arise after starting.

•

Check to make sure the attachment on your truck is

the same as on the truck capacity plate.

•

Check for hydraulic leaks and cracked hoses or

fittings. Check the hydraulic oil level in the lift truck

hydraulic reservoir.

•

All electrical cables and connectors must be in good

condition. Use caution in wet weather to avoid danger

from electrical shock.

•

Always check the attachment for proper fit and

engagement of the truck carriage.

3.8 Operation Warnings

•

You must be trained to operate this equipment prior

to operation. Be extremely careful if you do not

normally operate this machine. Reorient yourself to

the machine before starting, then proceed slowly.

•

Always operate an attachment from the driver’s seat.