13

45-074, REV. 5/18

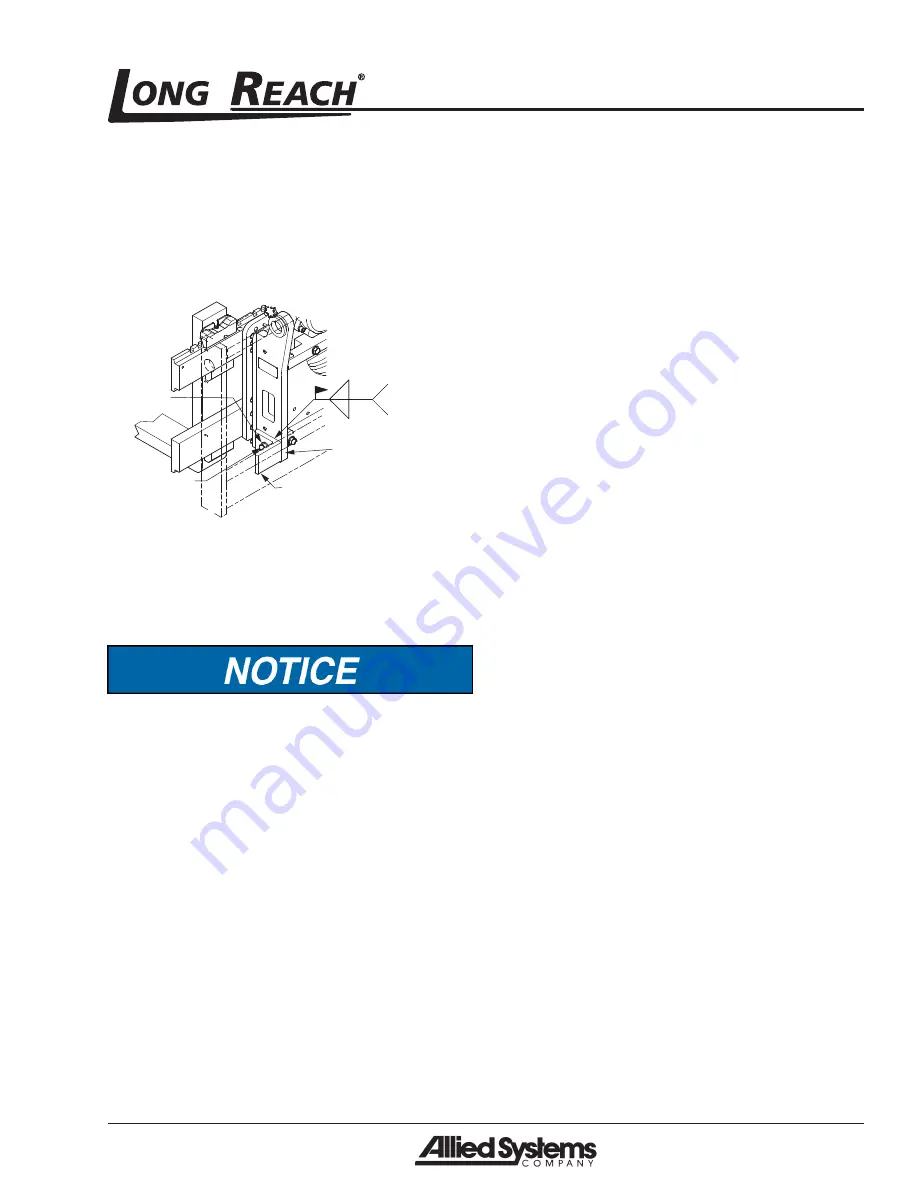

3. Install the pin-mount attachment to truck carriage.

Using the attachment as a template, weld on the

bracket lugs, supplied with the attachment, to lower

bar on the truck carriage. (Figure 4-2)

Truck Carriage

Mounting Lug

Capscrew

70,000 PSI

min. yield

strength typ.

.38

Washer

Figure 4-2, Pin-Mount Lug

4. Weld the bracket lugs with 7018 welding rod, or equiva-

lent, on each side of the truck carriage. Use provided

capscrews to secure attachment to truck carriage.

(Figure 4-3)

Equipment damage hazard.

E q u i p m e n t d a m ag e , p e r fo r m a n c e

reduction, personal injury and/or loss of

warranty could result if any alterations are

made to the original attachment.

Consult with factory before altering original

equipment.

4.3 Hydraulic Connections

1. Install the lines from the truck’s hydraulics to the

hydraulics of the attachment.

2. Inspect installation to ensure hoses are not kinked or

pinched between the truck carriage and attachment.

3. Operate the attachment continuously for several min-

utes to determine that all hydraulic connections are

secure with no leaks.

4. With the mast in the vertical position, rotate the attach-

ment fully 360°. After this procedure, check that the

truck’s hydraulic reservoir oil level is at the recom-

mended level.

5. Before placing the attachment in operation inspect

all hoses and fittings for leaks and routing clearance.

Be sure to include clearance of jumper hoses to the

mast.

6. After completing the installation, operate the attach-

ment without a load for several cycles to remove any

air in the hydraulic system. Test the attachment with a

load to make sure the attachment operates correctly.