22

45-074, REV. 5/18

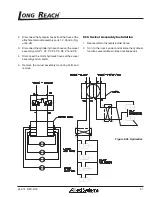

2. Place the motor in a vice and clamp across the edge of

the flange with output shaft down. When clamping, use

a protective device on the vise such as special soft jaws,

pieces of hard rubber or board. (Figure 5-22)

Figure 5-22, Motor Clamping

NOTICE

Equipment damage hazard.

Excessive clamping pressure on the side

of the housing causes distortion.

Use caution when clamping the motor

housing.

3. Remove the capscrews and seal washers (if appli-

cable) from the end cap. The seal on the end cap can

now be serviced. (Figure 5-23)

End cap

Capscrew

Seal

Washer

Figure 5-23, End Cap

4. Remove the gerotor and the drive spacer (if appli-

cable). The seal on the gerotor can now be serviced.

(Figure 5-24)

Gerotor

Drive spacer

Seal

Figure 5-24, Gerotor

5. Remove the drive and the spacer plate. The seal in

the housing can now be serviced. (Figure 5-25)

Figure 5-25, Drive

6. Remove the output shaft and the needle thrust bear-

ing from the housing.

7. Reposition the motor in the vise. Clamp the motor

across the ports as shown in (Figure 5-26). Do not

clamp on the side of the housing. Be careful not to

clamp too hard, as too much pressure could distort

the motor housing.