23

45-074, REV. 5/18

1/2 in. (13mm)

1/2 in. (13mm)

Figure 5-26, Motor Port Clamping

8. Remove capscrews from the mounting flange. These

capscrews are installed with Loctite and will require

300-400 lb-in of torque to break loose and 100 lb-in

of torque to remove.

CAUTION

Equipment damage hazard.

Impact wrenches could damage screws

or sockets if screws have been secured

with Loctite.

Use care when working with the gear

assembly. Do not use a impact wrench on

the screws that have been secured with

Loctite.

NOTICE

If torqued higher than given above is

required to break capscrews loose, apply

heat according to the following instructions.

Loctite partially melts when heated, reducing the

torque required to remove the capscrew. Use a small

flame propane torch to heat a small area of the

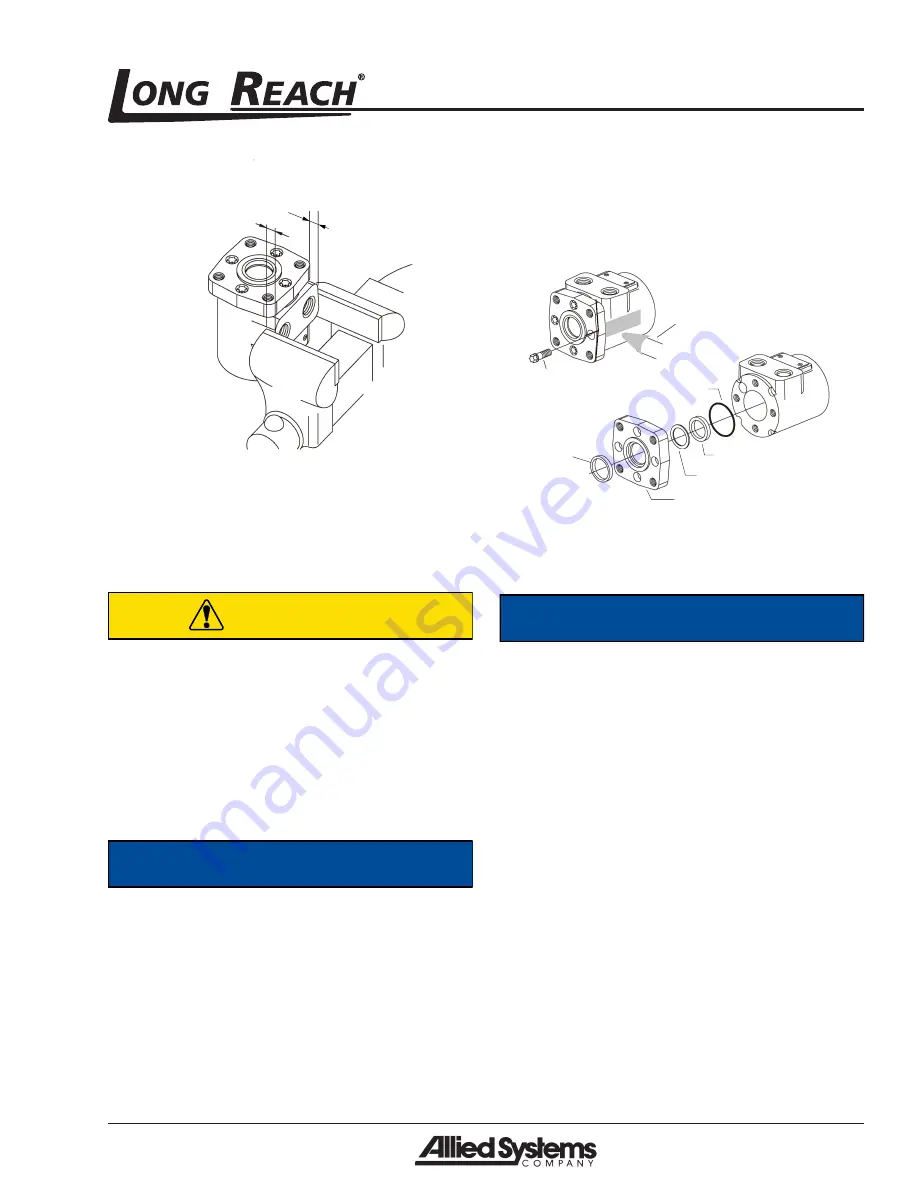

housing where the capscrew enters (Figure 5-27).

Be careful not to overheat the housing and damage the

motor.

Apply heat for 8 to 10 seconds while gradually applying

torque to the capscrew with a socket wrench. As soon as

the capscrew breaks loose, remove heat from the hous-

ing. Continue turning the capscrew until it is completely

removed.

Exclusion

Seal

Back-up Ring

Capscrew

Heat with a

propane torch

to melt Loctite

Pressure Seal

Mounting Flange

Seal

Figure 5-27, Capscrew Loctite

9. Carefully remove the mounting flange from the housing.

NOTICE

Some motors may have a quad seal and

back-up ring in place of the pressure seal.

The quad seal and back-up ring are no

longer available and are replaced by the

pressure seal. They are interchangeable,

but some precautions must be taken to

ensure proper installation. Follow the

reassembly instructions. (Section 5.8)

10. The exclusion seal, back-up ring, pressure seal and

seal will come off with the mounting flange (Figure

5-28).