24

45-074, REV. 5/18

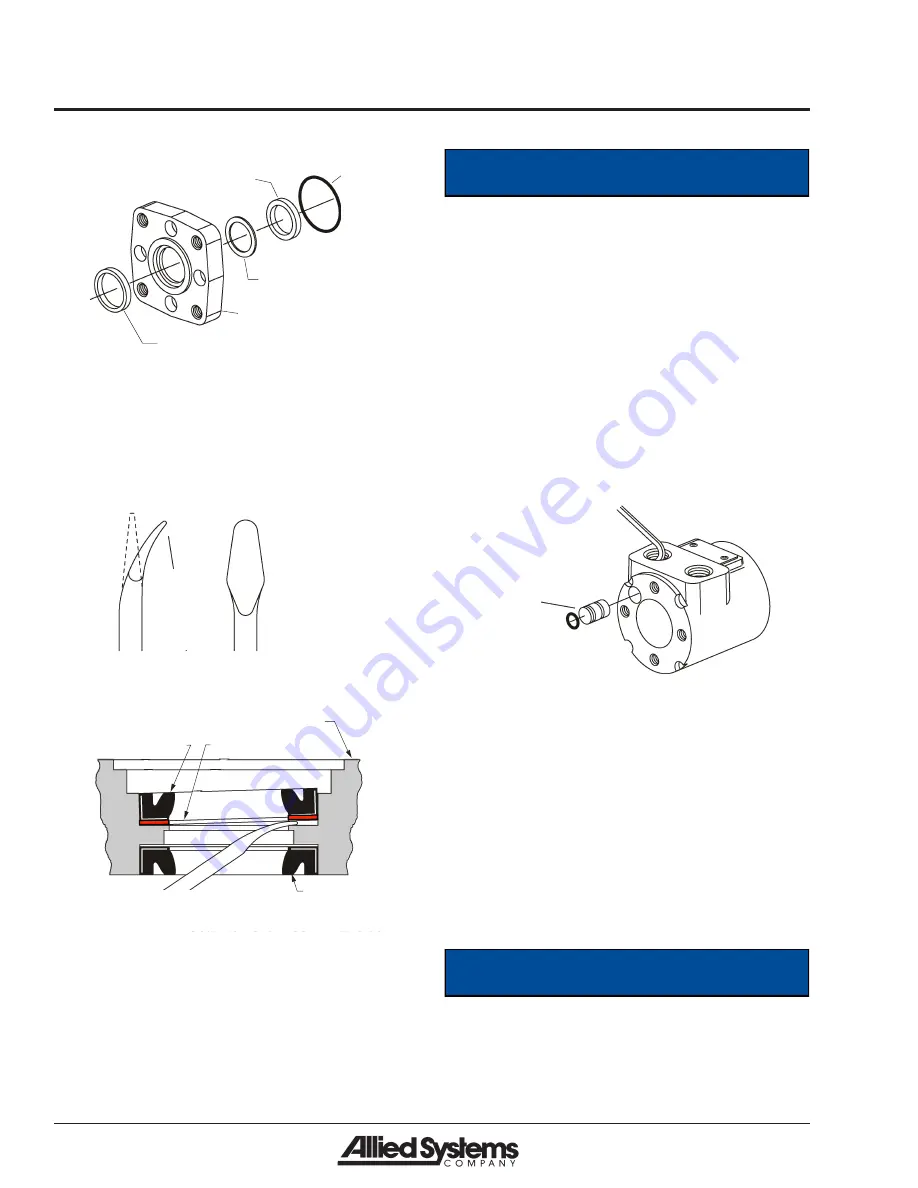

Pressure Seal

Mounting Flange

Exclusion Seal

Back-Up Ring

Seal

Figure 5-28, Mounting Flange Seals

Use a seal removal tool (Figure 5-29 and 5-30) to

remove the exclusion and pressure seals.

Radius

Bend tip

Radius

on end

Modify

screwdriver

as shown.

Remove

all burrs.

Figure 5-29, Seal Removal Tool

Exclusion

Seal

Back-up Ring

Pressure Seal

Mounting Flange

Seal Removal Tool

Figure 5-30, Seal Removal

NOTICE

Equipment damage hazard.

Any scratch or foreign material on the

surface of the seal cavity outer diameter

could create a leak path.

Be careful not to scratch the seal cavity

O.D. Use lint-free towels to wipe parts

11. Work from the outer side for both (either) seals.

12. A metal plug, with seal, plugs a machining hole in the

housing. It is not necessary to remove the plug and

replace seal unless leakage occurs around the plug.

To remove the plug, insert a 5 mm (.187 in.) hex key

through the port opening and push it out. (Figure 5-31)

Plug

Figure 5-31, Housing Plug

5.8 Motor Assembly

1. Check all mating surfaces. Replace any parts with

scratches or burrs that could cause leakage or dam-

age. Clean all metal parts in clean solvent. Blow dry

with air.

2. Check around the key slot and chamfered area of the

shaft for burrs, nicks or sharp edges that could dam-

age seals during reassembly. Remove nicks or burrs

with a hard smooth stone (such as an Arkansas stone).

Do not file or grind motor parts.

NOTICE

Lubricate all seals with petroleum jelly. Use

new seals when reassembling motor. Refer

to Parts Coverage.

Do not stretch seals before installing them.