25

45-074, REV. 5/18

NOTICE

Fully cured Loctite resists most solvents,

oils, gasoline and kerosene and is not

affected by cleaning operations. It is not

necessary to remove cured Loctite that is

securely bonded in tapped holes; however,

any loose particles of cured Loctite should

be removed.

A. Wash the housing with solvent to remove oil,

grease and debris. Pay particular attention to four

tapped holes on the flange end.

B. Blow dry with compressed air. Clean and dry

tapped holes.

C. Wire brush screw threads to remove cured Loc-

tite and other debris. Discard any capscrews that

have damaged threads or rounded heads.

D. Wash capscrews with non-petroleum base sol-

vent. Blow dry with compressed air.

3. If you remove a plug or seal, lubricate the new seal and

install on plug. Some plugs have two O-ring grooves

but require only one O-ring. Install O-ring in groove

closest to the end of the plug. Push the plug into the

housing so the plug and housing are flush. Be careful

not to damage the seal.

4. Lubricate the output shaft with hydraulic oil, then install

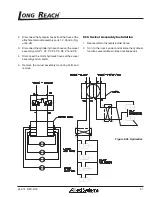

the output shaft into the housing. (Figure 5-32)

Output shaft

Bearing race

Lubricate these areas

Needle thrust bearing

Figure 5-32, Output Shaft

NOTICE

Do not permit oil to get into the four tapped

holes.

5. Install the needle thrust bearing, then the bearing race

onto the output shaft. Pull the output shaft partially out

of the housing. Push all three parts into the housing

together (Figure 5-33). The bearing race must rotate

freely when in position.

Figure 5-33, Output Shaft In Position

6. Install the exclusion seal into the mounting flange.

Carefully press the exclusion seal into place. (Figure

5-34)

Seal

Driver

Seal Tube

Backup

Ring

Mounting

Flange

Exclusion

Seal

Shaft

Pressure Seal

Figure 5-34, Seal Installation

7. Visually check the seal seat in the mounting flange

for scratches or other marks that might damage the

pressure seal. Check for cracks in the mounting flange

that could cause leakage.