26

45-074, REV. 5/18

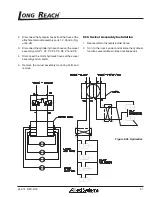

8. Lubricate the I.D. of the seal tube and O.D. of the shaft

pressure seal with a light film of clean petroleum jelly.

Align the small I.D. end of the seal tube with the seal

seat in the mounting flange. Install the back-up ring

and pressure seal in the tube with lips of the seal face

up (Figure 5-34). Insert the seal driver in the tube and

firmly push seal seat with a rotating action.

NOTICE

After installing the seal in the mounting

flange, examine the seals condition. If

damaged or improperly installed, you

must replace it before continuing with

reassembly.

9. Install the 49mm (1.937 in.) I.D. seal in the flange.

10. A light coat of Loctite Primer NF in tapped holes of

housing is recommended. Allow primer to air dry for at

least 1 minute. Do not force dry with air jet; the primer

will blow away.

NOTICE

Primer is optional. With primer, Loctite

curing time is approximately 15 minutes.

Without primer, curing time is approximately

6 hours.

11. Apply 3 or 4 drops of Loctite sealant at the top of the

threads for each of the four holes in the housing. Do

not allow parts with Loctite applied to come in contact

with any metal parts other than those for assembly.

Wipe off excess Loctite from the housing face, using

a non-petroleum base solvent.

NOTICE

Do not apply Loctite to threads more than

15 minutes before installing capscrews.

If the housing stands for more than 15

minutes, repeat application. No additional

cleaning or removal of previously applied

Loctite is necessary.

12. Before installing the mounting flange and seal assem-

bly over the shaft, place a protective sleeve or bullet

over the shaft. Then lubricate the space between the

exclusion seal and pressure seal, as well as the lips

of both seals. (Figure 5-35)

Dust Seal

Pressure

Seal

Output Shaft

Back-Up

Ring

Seal

Bearing

Race

Interior of

motor

This lip to

face inward

Apply petroleum jelly across this area

Figure 5-35, Output Shaft Lubrication

13. Install the mounting flange. Rotate the mounting flange

slowly while pushing down over the shaft. Be careful

not to invert or damage the seals.

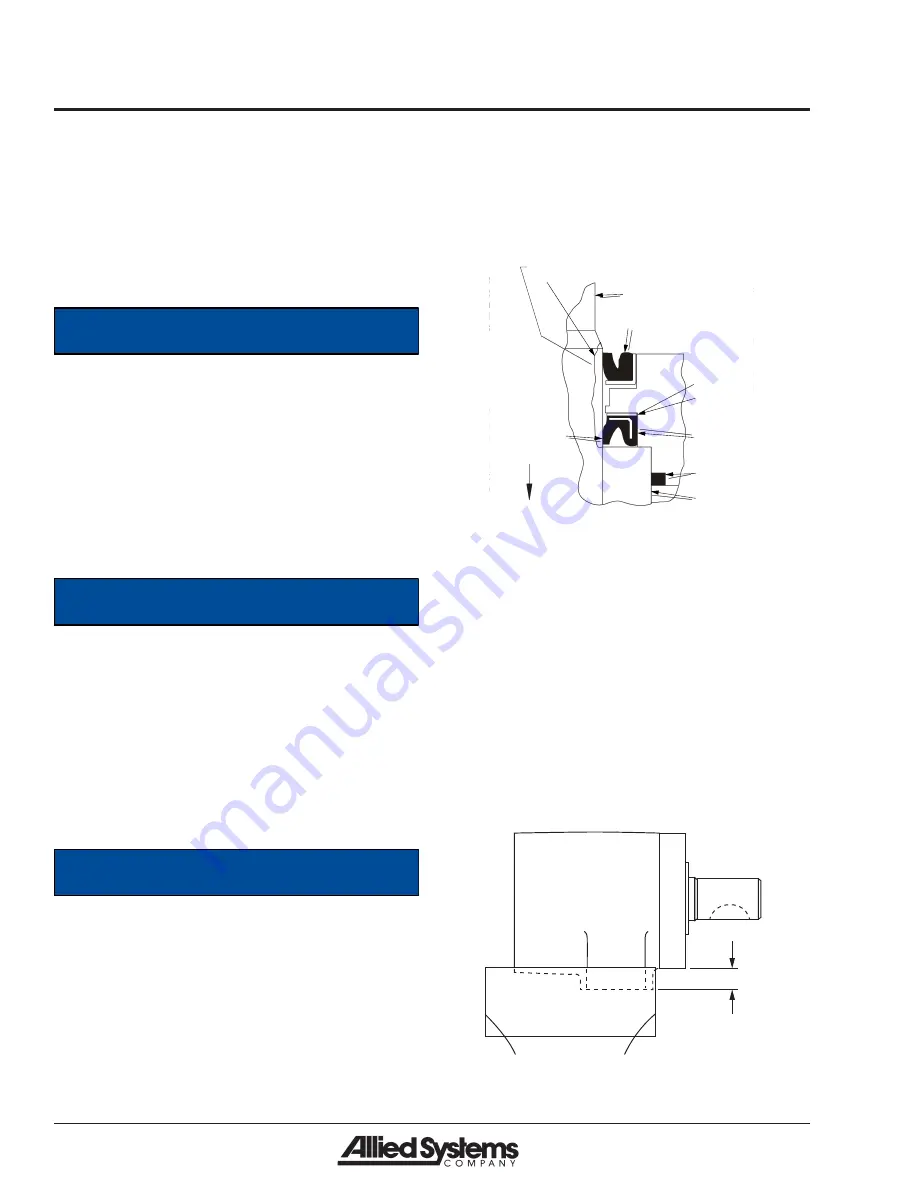

14. After removing the bullet, clamp the motor in a vise.

Make sure the shaft cannot fall out. Install dry cap-

screws and alternately torque them immediately to

250 lb-in. If you use a primer, allow to cure for 10 to

15 minutes. Without primer, allow 6 hours for curing

time before subjecting the motor to high torque rever-

sals. On all other applications, you can run the motor

immediately. (Figure 5-36)

1/2 in. (13mm)

Figure 5-36, Motor Clamping