45-008 REV. 1/22

15

SECTION 4 INSTALLATION PROCEDURE

4.1 Truck Requirements

Long Reach attachments have been designed to operate within specific limits. Oper-

ating pressures above the recommended maximum may cause damage to the attach-

ment and may void the warranty. Operating pressure specifications for your attachment

can be found on the attachment nameplate. (Section 1)

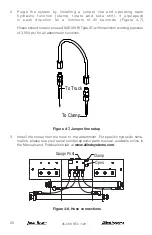

Hydraulic flow less than the recommended rates, or the use of small I.D. hoses may reduce

operating speed. Higher flow can result in excessive heat buildup, erratic operation and

damage to the truck/attachment hydraulic system. Hydraulic flow specifications for your

attachment can be found on the attachment nameplate. (Section 1)

The dealer and/or the user must provide and install the

valving required to meet the recommended hydraulic

pressures and flow, or must arrange installation of the

required valving at the truck factory.

The attachment model description, found on your shipped

invoice, will state the following truck requirements: flow

(gpm), psi, and minimum truck carriage width.

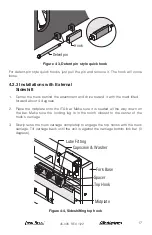

1. The truck carriage must conform to the American National Standard (ANSI) dimen-

sions shown in ANSI/ITSDF B56.11.4-2013.

2. Make sure the truck carriage is clean, conforms to ANSI recommendations, and

the notches are not damaged.

3. The truck hydraulic system must supply to the attachment hydraulic oil that meets

the specifications required to operate the attachment properly.

4. The truck hydraulic system must supply to the attachment hydraulic oil that meets

the specifications required to operate the attachment properly. Find specifications

for your attachment on the attachment nameplate. (Section 1)

4.2 Attachment Installation

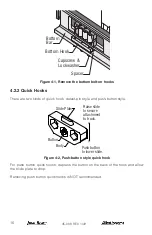

4.2.1 Bolt-On Hooks

First, remove the lower bolt-on hooks and, if applicable, make a note of any factory-in-

stalled shims. Shims are used to create space between the hook and carriage.