45-008 REV. 1/22

18

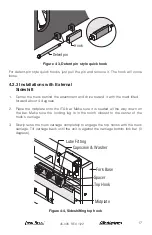

4. Inspect for proper engagement of the locking lug in the notch closest to the center

of the truck’s carriage.

5. Weld on the (optional) extra locking lug supplied with the attachment, (two pieces

of 1/2" x 1/2" x 2.00" steel, shipped loose) with either E-6011 or E-6013 welding

rod, or equivalent, on each side of the truck carriage.

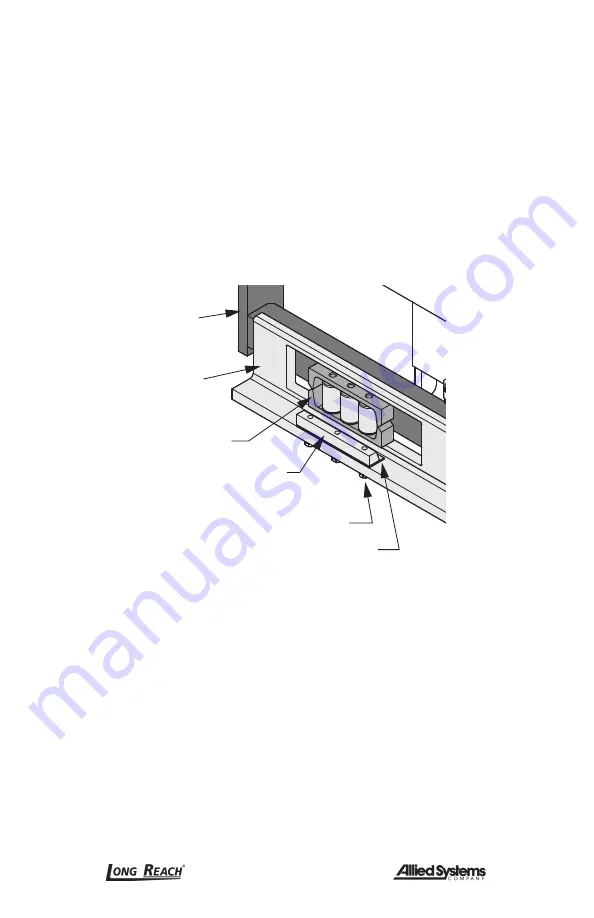

4.2.4 Lower Roller Assemblies (if Applicable)

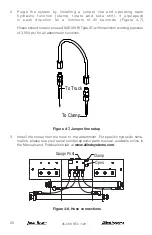

1. Move the attachment away from the carriage about two inches. Place a block

between the attachment and the carriage to hold it in position.

2. Place the rollers anywhere in the heel plate pockets on the lower right and left

hand sides of the attachment. They are a loose fit, and do not need to face a

particular direction.

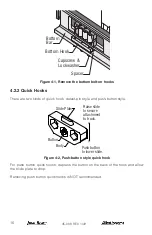

Midplate

Top Hook

Bottom

Bar

Bottom Hook

Spacer

Lower Roller

Assembly

Fork

Base

Capscrew &

Lockwasher

Fork Base

Capscrew & Washer

Spacer

Lube Fitting

Figure 4-5, Lower hooks and rollers for

sideshifter models

3. Gently move the bottom of the attachment out to remove the block. Lower the

attachment down the face of the carriage. Ensure that the rollers remained in the

pockets and are in contact with the carriage.

4. Install the bolt-on lower hooks. Inspect clearance between the carriage and the lower

hooks. Add or subtract shims under the lower hooks so the clearance is no more

than 3/32". On Class II and Class lll units, tighten the 3/8" bolts to

33 ft-lbs

. On Class

lV units tighten the 1/2" bolts to

77 ft-lbs.

On units using 9/16" UNC bolts, tighten the

bolts to

112

ft-lbs

.