45-008 REV. 1/22

8

3.7 Pre-start Checks

• Check your equipment before you operate it. If anything looks wrong, unusual or

different, report it before using the attachment.

• Do not operate this machine if you know of malfunctions, missing parts, and/or

mis-adjustments. These situations can cause or contribute to an accident or damage

to the machine. Stop the machine immediately if problems arise after starting.

• Check to make sure the attachment on your truck is the same as on the truck

capacity plate.

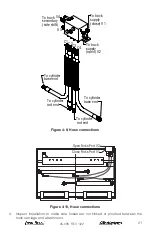

• Check for hydraulic leaks and cracked hoses or fittings. Check the hydraulic oil level

in the lift truck hydraulic reservoir.

• All electrical cables and connectors must be in good condition. Use caution in wet

weather to avoid danger from electrical shock.

• Always check the attachment for proper fit and engagement of the truck carriage.

3.8 Operation Warnings

• You must be trained to operate this equipment prior to operation. Be extremely careful

if you do not normally operate this machine. Reorient yourself to the machine before

starting, then proceed slowly.

• Always operate an attachment from the driver’s seat.

• Always lower the attachment if you need to leave the lift truck. A lift truck supporting

a load requires your full attention.

3.9 Hydraulic Hazards

DANGER

Injection hazard.

Infection and gangrene will result when hydraulic oil

penetrates the skin. See a doctor immediately to prevent

loss of limb or death.

Use a piece of cardboard to check for hydraulic leaks.

• Wear personal protective equipment, such as gloves and safety glasses, whenever

servicing or checking a hydraulic system.

• Assume that all hydraulic hoses and components are pressurized. Relieve all

hydraulic pressure before disconnecting any hydraulic line.

• Never try to stop or check for a hydraulic leak with any part of your body; use a

piece of cardboard to check for hydraulic leaks.