11

Operation Instructions

1. Do not operate the blower in the fully raised position. The three-point hitch on some tractors

raises high enough to cause the PTO shaft to bind. This can cause damage to the PTO shaft

and/or to the hitch and pins.

NOTE:

PTO shaft angle should not exceed 20° for optimum

performance and life. Damage may occur to PTO and/or snowblower if angle becomes more

extreme.

2. Depth of cut can be partially controlled by tilting the blower forward or backward. Adjust the

top link of the tractor hitch so the snowblower is just slightly tilted back when resting on the

ground.

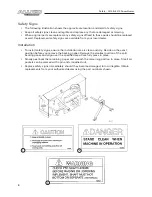

CAUTION

Excessive backward tilt may cause the “U” joints to flutter

resulting in PTO shear bolt failure.

3. Adjust the lower link sway chains or blocks on the tractor to restrict side movement of the

blower when operating

4. Run the blower at low rpm to check operation before blowing snow.

5. The snowblower has two shear bolts to protect the tractor and blower in case a large object

enters the blower. PTO shear bolts – 50" - one 3/8" x 1" (gr.8), 60" - two - 5/16" x 1" (gr. 8), auger

shear bolt - 1/4" x 1" (gr. 2). Shear bolts should be fastened with a lock nut or two jam nuts.

These bolts must be kept tight to prevent wear of the bolt and bolt holes.

6. Never run PTO shaft at over 600 rpm.

7. Chain Tension: Slack on the lower side of the chain should be 3/8 to 1/2".

8. Lubrication:

- The spout clamps and rings should be periodically lubricated with gun grease.

- PTO shaft universal joints and square shaft slide should be greased daily.

- PTO shear yoke should be greased before using the blower for the first time.

- Regularly oiling the chain will significantly increase the life of the chain.

- Gearbox is open type and need not be greased or lubricated.

- Hydraulic spout option – grease the swivel arm.

9. Periodically check all bolts for tightness. The bolt holding on the fan and the bearing bolts are

of particular importance.

DANGER

Always stop blower for servicing or unplugging. The PTO should

be disengaged before dismounting from the tractor.

Operation - 5010 & 6010 Snowblower

Summary of Contents for 5010

Page 1: ...Snowblower Models 5010 6010 OPERATOR AND PARTS MANUAL 102010 FK312 ...

Page 2: ......

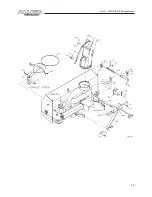

Page 14: ...14 Parts 5010 6010 Snowblower Snowblower Drawings ...

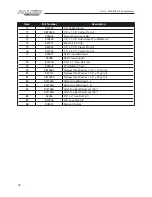

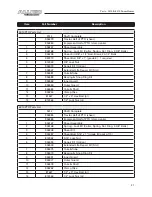

Page 15: ...15 Parts 5010 6010 Snowblower ...

Page 19: ......

Page 20: ...20 Parts 5010 6010 Snowblower PTO Shaft Drawing ...

Page 27: ......