508142-01

Issue 2047

Page 17 of 33

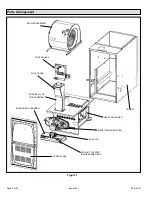

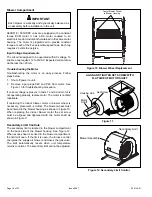

Combustion Air Inducer (B6)

All A80DF1E / 80G1DFE units use a combustion air inducer

to move air through the burners and heat exchanger during

heating operation. The blower uses a 120VAC motor.

The motor operates during all heating operation and is

controlled by integrated control A92. The inducer also

operates for 15 seconds before burner ignition (pre-purge)

and for 5 seconds after the gas valve closes (post-purge).

A pressure switch mounted on the combustion air inducer

orifice plate is used to prove inducer operation. The

combustion air inducer orifice will be different for each

model. The switch monitors air pressure in the inducer

housing. During normal operation, the pressure in the

housing is negative. If pressure becomes less negative

(signifying any obstruction in the flue) the pressure switch

opens. When the pressure switch opens, the integrated

control (A92) immediately de-energizes the gas valve to

prevent burner operation.

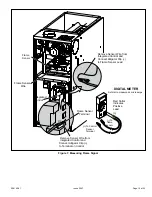

Combustion Air Inducer Pressure Switch (S18)

A80DF1E / 80G1DFE series units are equipped with a

combustion air pressure switch located on the combustion

air inducer orifice bracket. The switch is connected to the

combustion air inducer housing by means of a flexible

silicone hose. It monitors negative air pressure in the

combustion air inducer housing.

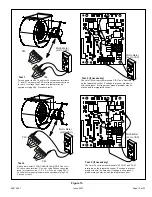

The switch is a single-pole single-throw proving switch

electrically connected to the furnace control. The

purpose of the switch is to prevent burner operation if

the combustion air inducer is not operating or if the flue

becomes obstructed.

On start-up, the switch senses that the combustion air

inducer is operating. It closes a circuit to the integrated

control when pressure inside the combustion air inducer

decreases to a certain set point. Set points vary depending

on unit size. See Table 7. The pressure sensed by the

switch is negative relative to atmospheric pressure. If

the flue becomes obstructed during operation, the switch

senses a loss of negative pressure (pressure becomes

more equal with atmospheric pressure) and opens the

circuit to the integrated control and gas valve. A bleed port

on the switch allows relatively dry air in the vestibule to

purge switch tubing, to prevent condensate build up.

The switch is factory set and is not field adjustable. It is a

safety shut-down control in the furnace and must not be

bypassed for any reason. If switch is closed or by-passed,

the integrated control will not initiate ignition at start up.

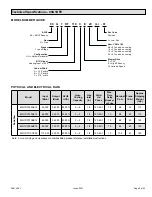

Unit

Break ±

0.05

(in. w.c.)

045

-0.60

070

-0.65

090

-0.60

110

-0.65

Table 7.

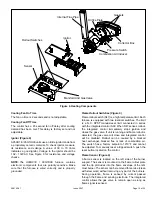

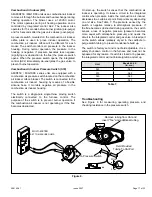

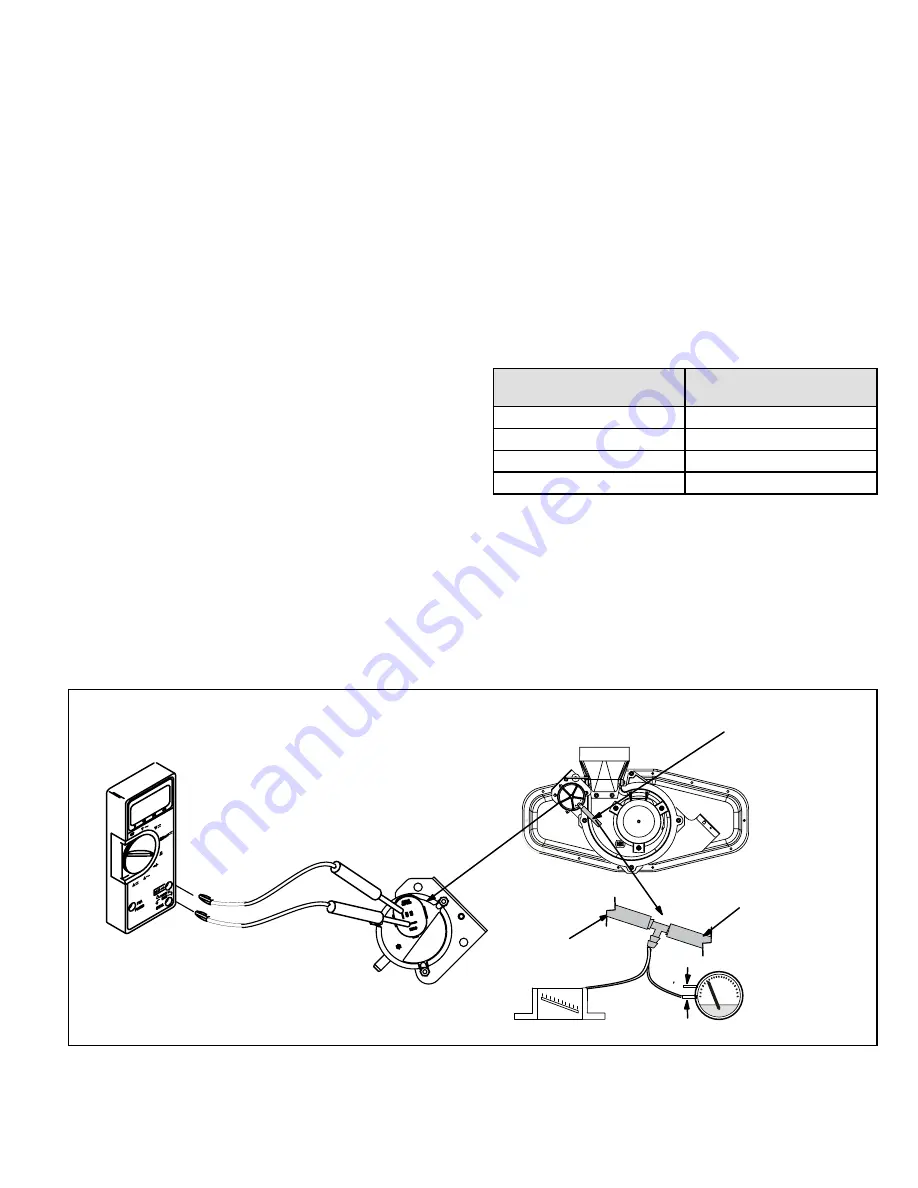

Troubleshooting

See Figure 9 for measuring operating pressure and

checking resistance in the pressure switch.

Figure 9.

MULTI−METER

SET TO MEASURE OHMS

+

-

or

Field Provided

Tubing To CAI Port

To Pressure Switch

Remove tubing from CAI and

insert “Tee” and additional tubing.

High

Low