508145-01

Page 10 of 36

Issue 2128

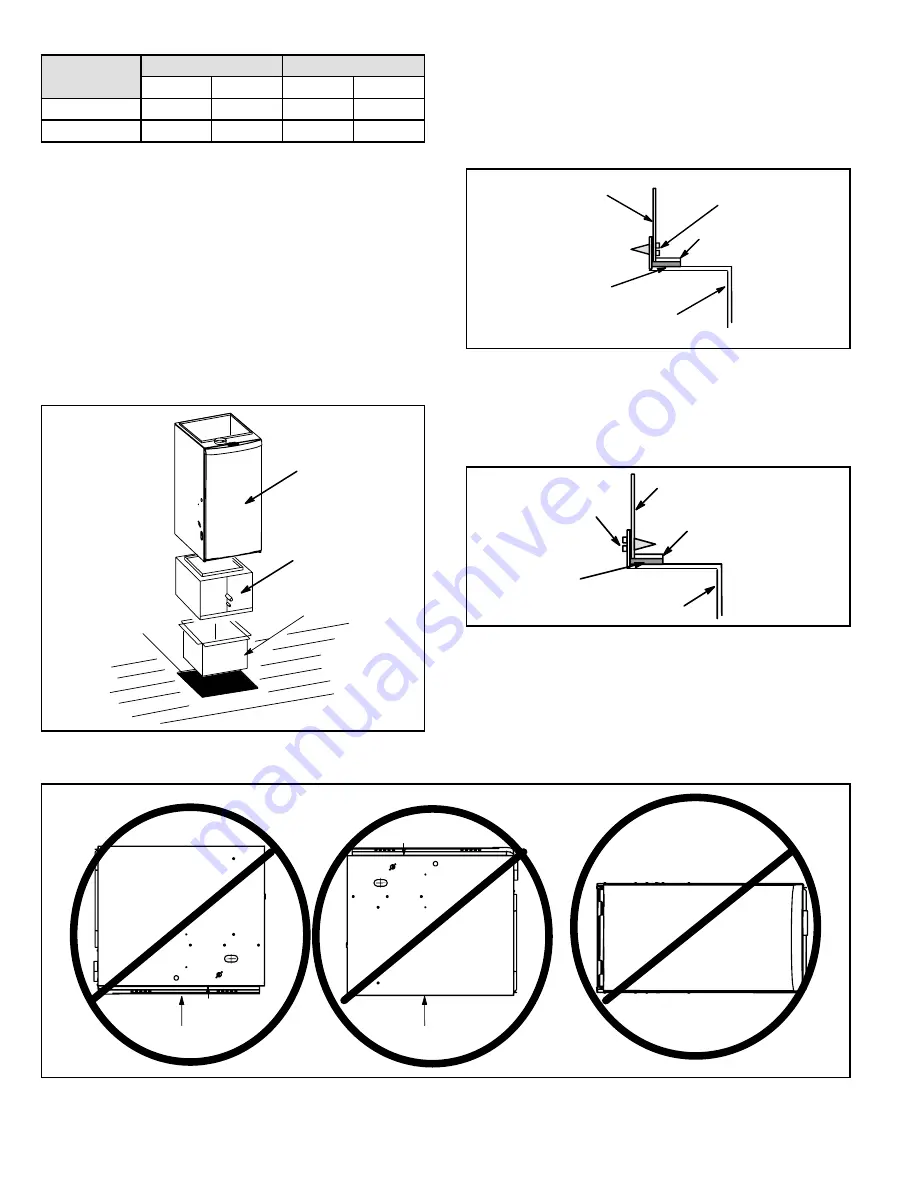

Return Air Opening -- Downflow Units

The following steps should be taken when installing

plenum:

1. Bottom edge of plenum should be flanged with a

Figure 11.

SECURE FROM

OUTSIDE CABINET

HEMMED EDGE

PLENUM

SEALING STRIP

(Field Provided)

CABINET SIDE PANEL

Side View

2. Sealing strip should be used.

3. In all cases, plenum should be secured to top flanges

of furnace with sheet metal screws.

Figure 12.

INSIDE CABINET

HEMMED EDGE

FIBERGLASS

SEALING STRIP

(Field Provided)

CABINET SIDE

PANEL

PLENUM

Side View

SECURE FROM

4.

In closet installations, it may be impossible to install

sheet metal screws from the outside. In this case,

make plenum with a removable front and install screws

from the inside (see Figure 12).

5. Make certain that an adequate seal is made.

Cabinet

Width

Front to Rear

Side to Side

in

mm

in

mm

A (14-1/2”)

22

559

15-3/4

400

B (17-1/2”)

22

559

18-3/4

476

Table 2.

Combustible Floor Opening Size

Installation on Cooling Cabinet

1. Refer to reverse-flow coil installation instructions for

correctly sized opening in floor and installation of

cabinet.

NOTE:

Downflow combustible flooring kit is not used.

2. When cooling cabinet is in place, set and secure the

furnace according to the instructions that are provided

with the cooling coil. Secure the furnace to the cabinet.

3. Seal the cabinet and check for air leaks.

Figure 10.

UNIT

COOLING COIL

PLENUM

PROPERLY

SIZED FLOOR

OPENING

Figure 13.

Front

Back

Horizontal