508145-01

Issue 2128

Page 11 of 36

Filters

This unit is not equipped with a filter or rack. A field provided

high velocity filter is required for the unit to operate properly.

Table 3 lists recommended filter sizes.

A filter must be in place any time the unit is operating.

If a high-efficiency filter is being installed as part of this

system to ensure better indoor air quality, the filter must

be properly sized. High-efficiency filters have a higher

static pressure drop than standardefficiency glass/foam

filters. If the pressure drop is too great, system capacity

and performance may be reduced. The pressure drop

may also cause the limit to trip more frequently during

the winter and the indoor coil to freeze in the summer,

resulting in an increase in the number of service calls.

Before using any filter with this system, check the

specifications provided by the filter manufacturer

against the data given in the appropriate Technical

Specification.

WARNING

Furnace Cabinet Width

Return Air Filter Size

(in.)

A - 14-1/2”

14 x 25 x 1

B - 17-1/2”

16 x 25 x 1

Table 3.

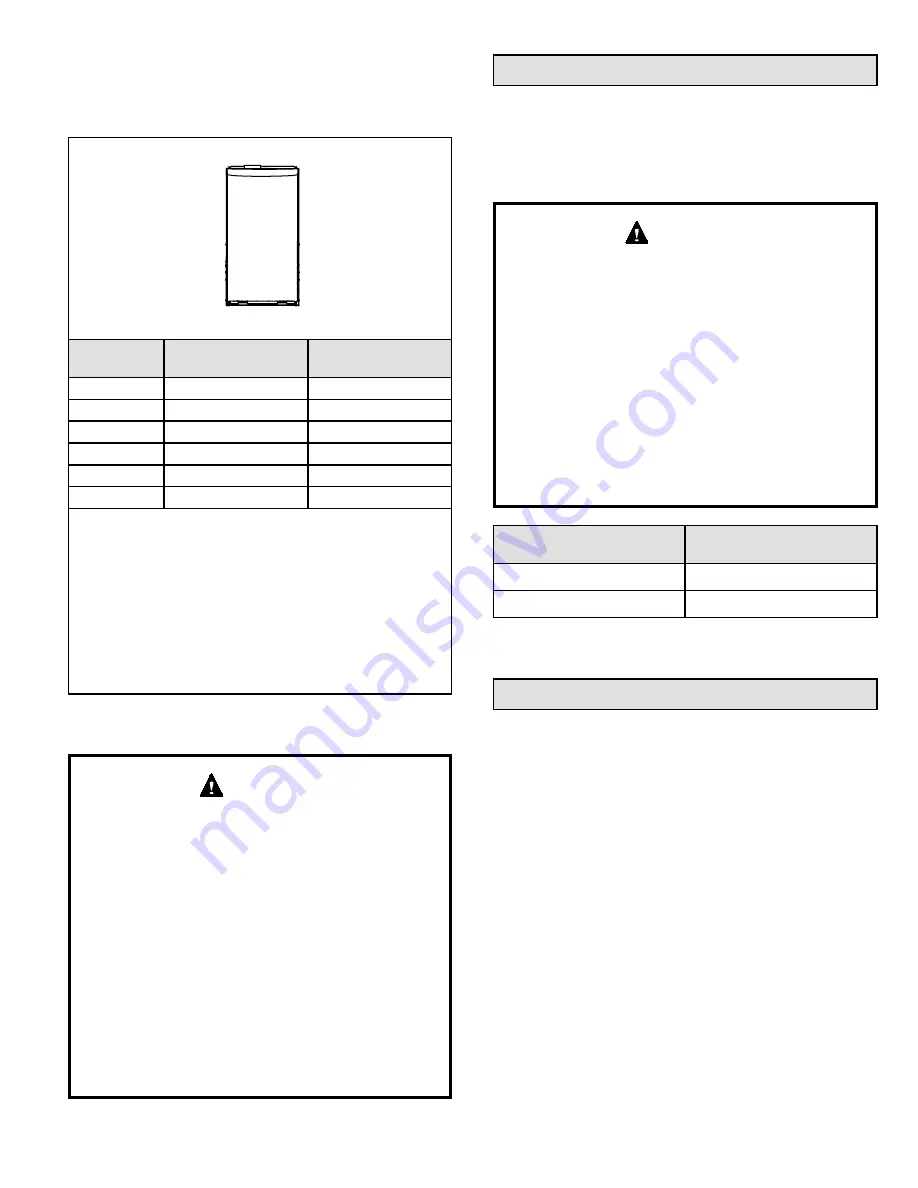

Downflow Application

Allow for clearances to combustible materials as indicated

on the unit nameplate. Minimum clearances for closet or

alcove installations are shown in Figure 14.

Top

Bottom

Left Side

Right Side

Figure 14.

Downflow Application Installation

Clearances

Type of Vent

Connector

Type C

Type B

1

Top

1 in. (25 mm)

1 in. (25 mm)

*Front

2-1/4 in. (57 mm) **

2-1/4 in. (57 mm) **

Back

0

0

Sides

0 †

0

Vent

6 in. (152 mm)

1 in. (25 mm)

Floor

NC ††

NC ††

* Front clearance in alcove installation must be 24 in. (610

mm). Maintain a minimum of 24 in. (610 mm) for front service

access.

** 3-1/4 in. if single wall vent pipe is used.

† Left side requires 3 in. if a single wall vent is used on 14-1/2

in. cabinets, or 2 in. if a single wall vent is used on 17-1/2 in.

cabinets.

†† The furnace may be installed on a combustible wood floor

if an optional additive base is installed between the furnace

and the combustible floor.

Improper installation of the furnace can result in

personal injury or death. Combustion and flue products

must never be allowed to enter the return air system or

the living space. Use screws and joint tape to seal the

return air system to the furnace.

In platform installations with bottom return air, the

furnace should be sealed airtight to the return air plenum.

A door must never be used as a portion of the return air

duct system. The base must provide a stable support

and an airtight seal to the furnace. Allow absolutely no

sagging, cracks, gaps, etc. The return and supply air

duct systems must never be connected to or from other

heating devices such as a fireplace or stove, etc. Fire,

explosion, carbon monoxide poisoning, personal injury

and/or property damage could result.

WARNING

Duct System

Use industry approved standards (such as those published

by Air Conditioning Contractors of America or American

Society of Heating, Refrigerating and Air Conditioning

Engineers) to size and install the supply and return air duct

system. This will result in a quiet and low static system that

has uniform air distribution.

NOTE:

Do not operate the furnace in the heating mode

with an external static pressure that exceeds 0.8 inches

w.c. Higher external static pressures may cause erratic

limit operation.

Ensure that you have made a seal between the supply air

plenum and the furnace and between the furnace and the

return air plenum.

Return Air Plenum

NOTE:

Return air must not be drawn from a room where

this furnace, or any other gas fueled appliance (i.e., water

heater), or carbon monoxide producing device (i.e., wood

fireplace) is installed.