507335-02

Page 26 of 39

Issue 2001

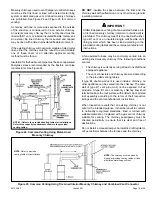

Connect a sufficiently sized wire with ground to the

furnace’s line voltage connections and ground wire. Refer

to the furnace rating plate for electrical characteristics

to be used in sizing field supply wiring and overcurrent

protection.

The line voltage supply should be routed through a readily

accessible disconnect located within sight of the furnace. A

junction box on the furnace side panel is provided for line

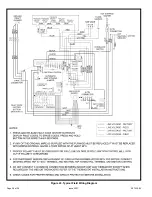

voltage connections. Refer to the furnace wiring diagram

for specific connection information.

Proper polarity of the supply connections (“HOT” and

“NEUTRAL”) must be observed to ensure that safety

controls provide the protection intended.

A connection to the unit’s ground wire and actual earth

ground (typically a ground stake or buried steel pipe) must

be maintained for proper operation.

Thermostat

Install a room thermostat according to the instructions

furnished with it. Select a location on an inside wall that

is not subject to drafts, direct sunshine, or other heat

sources. The initial heat anticipator setting should be equal

to the total current draw of the control circuit. Low voltage

thermostat connections are to be made to the integrated

ignition/blower control board as indicated on the wiring

diagram.

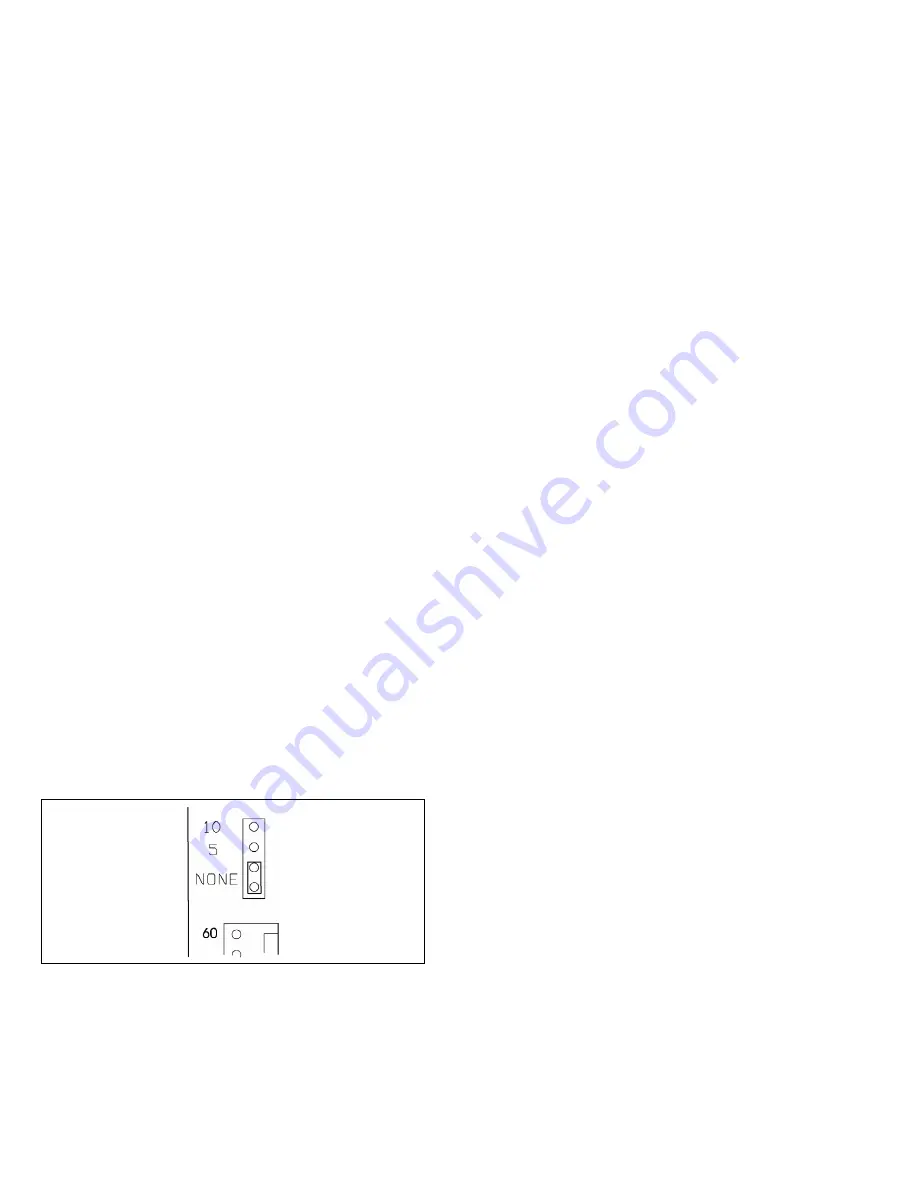

Single Stage Thermostat Operation (80G2UH-V )

The automatic heat staging option allows a single stage

thermostat to be used with two stage furnace models

(

80G2UH-V). To activate this option, move the jumper

pin (see Figure 31) to desired setting (5 minutes or 10

minutes). The furnace will start on 1st stage heat and

stay at 1st stage heat for the duration of the selected time

before switching to 2nd stage heat.

W1 on the control board must be connected to W1 on the

thermostat.

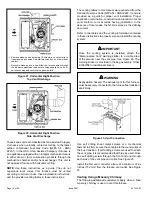

Figure 31. Automatic Heat Staging Jumper

Humidifier

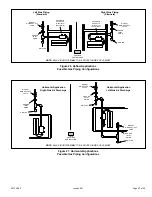

Terminals are provided on the integrated ignition/blower

control board for connection to a 120-volt humidifier. The

“HUM” terminal is energized whenever the thermostat

calls for heat. See the furnace wiring diagram for specific

connection information.

Electronic Air Cleaner

Terminals are provided on the integrated ignition/blower

control board for connection of a 120-volt electronic air

cleaner. The “EAC” terminal is energized whenever the

thermostat calls for heat, cooling, or continuous blower. See

furnace wiring diagram for specific connection information.

Variable Speed Features

This furnace is equipped with a variable speed circulation

air blower motor that will deliver a constant airflow within a

wide range of external static pressures. Other features of

this variable speed motor include:

Soft Start

The variable speed motor will slowly ramp up to normal

operating speed. This minimizes noise and increases

comfort by eliminating the initial blasts of air encountered

with standard motors.

Soft Stop

At the end of a cooling or heating cycle, the variable speed

motor will slowly ramp down after a short blower “off” delay.

If continuous blower operation has been selected, the

variable speed motor will slowly ramp down until it reaches

the airflow for that mode.

Passive and Active Dehumidification

Passive Dehumidification

For situations where humidity control is a problem, a

dehumidification feature has been built into the variable

speed motor. At the start of each cooling cycle, the variable

speed motor will run at 82% of the rated airflow for 7.5

minutes. After 7.5 minutes has elapsed, the motor will

increase to 100% of the rated airflow.

Active Dehumidification

To achieve additional dehumidification, clip the jumper

wire located below the DEHUM terminal on the integrated

ignition/blower control board and connect a humidity

control that opens on humidity rise to the DEHUM and

R terminals. The DEHUM terminal on the control board

must be connected to the normally closed contact of the

humidity control so that the board senses an open circuit

on high humidity. In this setup, the variable speed motor

will operate at a 18% reduction in the normal cooling airflow

rate when there is a call for dehumidification.

Both the passive and active dehumidification methods

described above can be utilized on the same furnace.