507271-02

Page 39 of 52

Issue 1621

Priming Condensate Trap

The condensate trap should be primed with water prior to

start-up to ensure proper condensate drainage. Either pour

10 fl. oz. (300 ml) of water into the trap, or follow these steps

to prime the trap:

1. Follow the lighting instructions to place the unit into

operation.

2. Set the thermostat to initiate a heating demand.

3. Allow the burners to fire for approximately 3 minutes.

4. Adjust the thermostat to deactivate the heating demand.

5. Wait for the combustion air inducer to stop. Set the

thermostat to initiate a heating demand and again allow

the burners to fire for approximately 3 minutes.

6. Adjust the thermostat to deactivate the heating demand

and wait for the combustion air inducer to stop. At this

point, the trap should be primed with sufficient water

to ensure proper condensate drain operation.

If you do not follow these instructions exactly, a fire

or explosion may result causing property damage,

personal injury or death.

WARNING

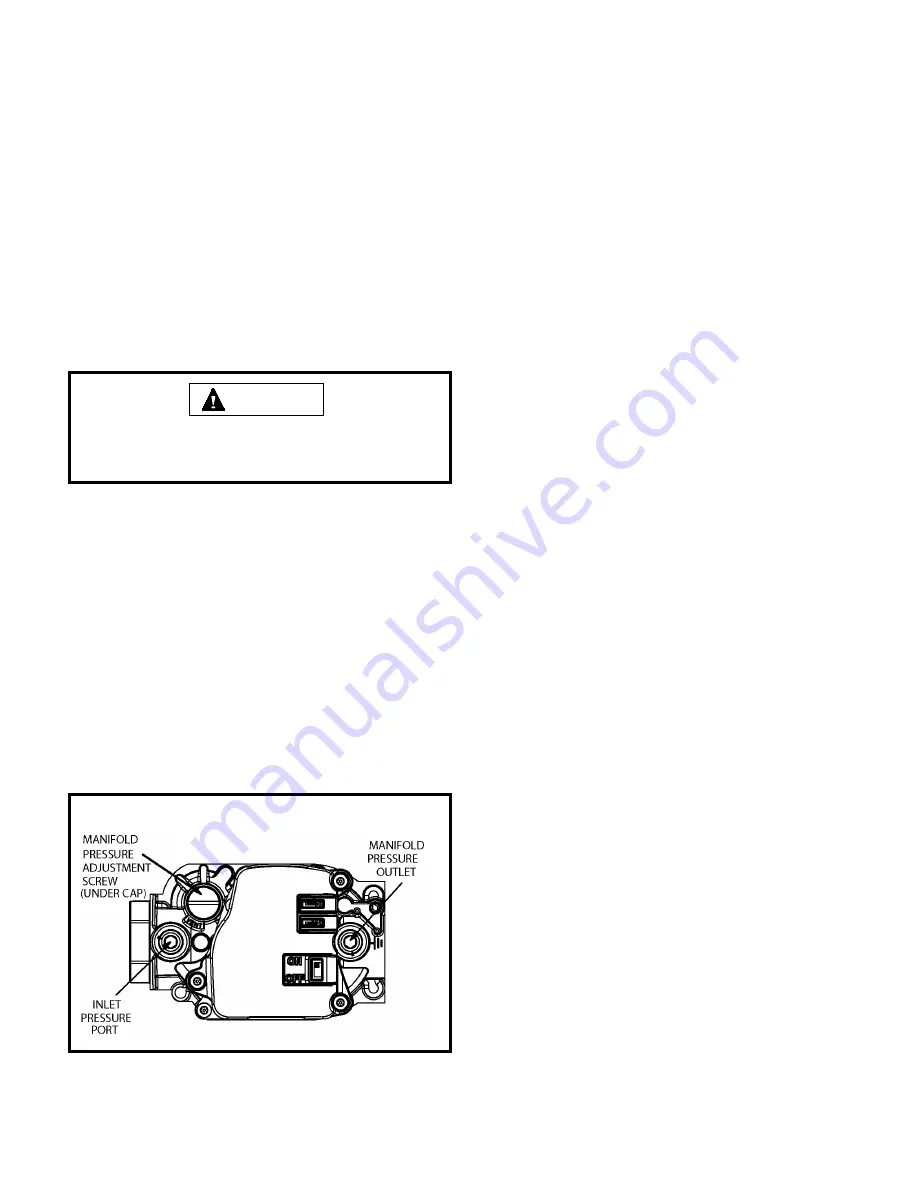

Gas Valve Operation (Figure 59)

1.

STOP

! Read the safety information at the beginning of

this section.

2. Set the thermostat to the lowest setting.

3. Turn

OFF

all electrical power to the unit.

4. This furnace is equipped with an ignition device which

automatically lights the burners. Do

not

try to light the

burners by hand.

5. Remove the heating compartment access panel.

6. Move gas valve switch to

OFF.

See Figure 59.

7. Wait five minutes to clear out any gas. If you then

smell gas,

STOP!

Immediately call your gas supplier

from a neighbor’s phone. Follow the gas supplier’s

instructions. If you do not smell gas go to next step.

8. Move gas valve switch to

ON.

See Figure 59.

9. Replace the heating compartment access panel.

10. Turn on all electrical power to the unit.

11. Set the thermostat to desired setting.

NOTE:

When unit is initially started, steps 1 through 11 may

need to be repeated to purge air from gas line.

12. If the appliance will not operate, follow the instructions

“Turning Off Gas to Unit” and call your service technician

or gas supplier.

Turning Off Gas to Unit

1. Set the thermostat to the lowest setting.

2. Turn off all electrical power to the unit if service is to be

performed.

3. Remove the heating compartment access panel.

4. Move gas valve switch to

OFF.

5. Replace the heating compartment access panel.

Failure To Operate

If the unit fails to operate, check the following:

1. Is the thermostat calling for heat?

2. Are access panels securely in place?

3. Is the main disconnect switch closed?

4. Is there a blown fuse or tripped breaker?

5. Is the filter dirty or plugged? Dirty or plugged filters will

cause the limit control to shut the unit off.

6. Is gas turned on at the meter?

7. Is the manual main shut–off valve open?

8. Is the internal manual shut–off valve open?

9. Is the unit ignition system in lockout? If the unit locks

out again, inspect the unit for blockages.

Heating Sequence Of Operation

1. When thermostat calls for heat, combustion air inducer

starts.

2. Combustion air pressure switch proves blower operation.

Switch is factory set and requires no adjustment.

3. After a 15 second prepurge, the hot surface ignitor

energizes.

4. After a 20 second ignitor warm-up period, the gas valve

solenoid opens. A 4-second “Trial for Ignition” period

begins.

5. Gas is ignited, flame sensor proves the flame, and the

combustion process continues.

6.

If flame is not detected after first ignition trial, the

ignition control will repeat steps 3 and 4 four more times

before locking out the gas valve. The ignition control

will then automatically repeat steps 1 through 6 after

60 minutes. To interrupt the 60 minute lockout period,

move thermostat from “Heat” to “OFF” then back to

“Heat”. Heating sequence then restarts at step 1.

Figure 59

Gas Valve Shown In “ON’ Position

Summary of Contents for 92G1DF-P

Page 17: ...507271 02 Page 17 of 52 Issue 1621 A95DF 95G1DF and A93DF 92G1DF Table 7 ...

Page 18: ...507271 02 Page 18 of 52 Issue 1621 A95DF 95G1DF and A93DF 92G1DF Table 8 ...

Page 31: ...507271 02 Page 31 of 52 Issue 1621 Figure 49 Trap Drain Assembly Using 1 2 PVC or 3 4 PVC ...

Page 36: ...507271 02 Page 36 of 52 Issue 1621 Figure 56 Typical Wiring Diagram For A93DF 92G1DF ...

Page 37: ...507271 02 Page 37 of 52 Issue 1621 Typical Wiring Diagram Figure 57 For A95DF 95G1DF ...

Page 50: ...507271 02 Page 50 of 52 Issue 1621 Start Up Performance Check List ...