508134-01

Issue 2045

Page 45 of 56

Supply Pressure Measurement

When testing supply gas pressure, use the 1/8” N.P.T.

plugged tap located on the gas valve to facilitate test gauge

connection. See Figure 49. Check gas line pressure with

unit firing at maximum rate. Low pressure may result in

erratic operation or underfire. High pressure can result in

permanent damage to gas valve or overfire.

On multiple unit installations, each unit should be checked

separately, with and without other units operating. Supply

pressure must fall within range listed in Table 16.

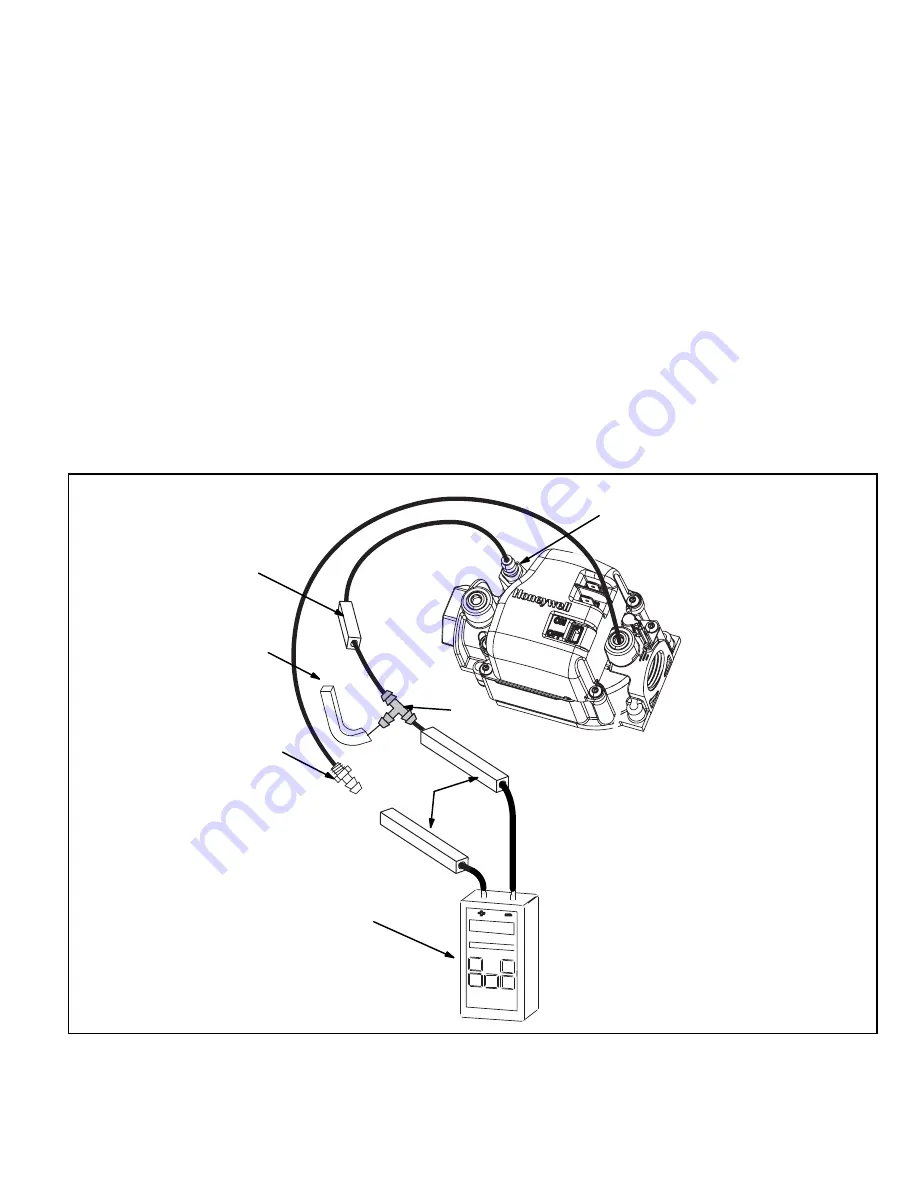

Manifold Pressure Measurement

After line pressure has been checked and adjusted, check

manifold pressure. Move pressure gauge to outlet pressure

tap located on unit gas valve (GV1).

Checks of manifold pressure are made as verification of

proper regulator adjustment.

1.

Connect the test gauge positive side “+“ to manifold

pressure tap on gas valve.

2.

Tee into the gas valve regulator vent hose and connect

to test gauge negative “-”.

3.

Start unit and let run for 5 minutes to allow for steady

state conditions.

4.

After allowing unit to stabilize for 5 minutes, record

manifold pressure and compare to value given in

5.

Shut unit off and remove manometer as soon as an

accurate reading has been obtained. Take care to

remove barbed fitting and replace threaded plug.

6.

Start unit and perform leak check. Seal leaks if found.

(+)

(−)

Gas Valve Regulator

Vent Hose

(to burner box)

2” Long Square Tubing

(remove for manifold adjustment)

Tee

10” Long

Square

Tubing

Measuring Device

Barbed Fitting

Manifold Pressure Outlet

Negative Barbed Fitting

(remove for manifold adjustment)

Figure 51.