508115-01

Issue 2043

Page 31 of 57

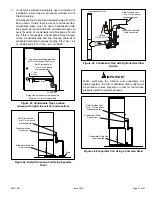

Intake Piping

The A95DF1E / 95G1DFE furnace may be installed in

either direct vent or non-direct vent applications.

In

non-direct vent applications, when intake air will be drawn

into the furnace from the surrounding space, the indoor

air quality must be considered and guidelines listed in

Combustion, Dilution and Ventilation Air section must be

followed.

Follow the next two steps when installing the unit in

Direct

Vent applications

, where combustion air is taken from

outdoors and flue gases are discharged outdoors.

The

provided air intake screen must not be used in direct

vent applications (outdoors).

1.

Use transition solvent cement or a sheet metal screw

to secure the intake pipe to the inlet air connector.

2.

Route piping to outside of structure. Continue with

installation following instructions given in general

guidelines for piping terminations and intake and

exhaust piping terminations for direct vent sections.

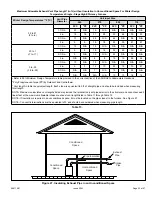

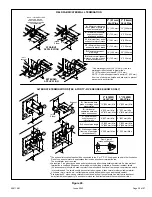

Refer to Table 11 and Table 12 for pipe sizes.

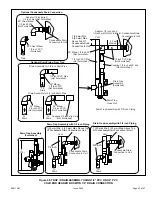

Follow the next two steps when installing the unit in

Non-

Direct Vent applications

where combustion air is taken

from indoors and flue gases are discharged outdoors.

1.

Use field-provided materials and the factory-provided

air intake screen to route the intake piping as shown

in Figure 24. Maintain a minimum clearance of 3”

(76mm) around the air intake opening. The air intake

opening (with the protective screen) should always be

directed forward, or sideways.

2.

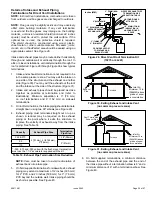

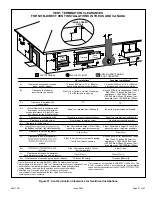

If intake air is drawn from a ventilated attic (Figure

25) or ventilated crawlspace (Figure 26) the exhaust

vent length must not exceed those listed in Table 12.

If 3” diameter pipe is used, reduce to 2” diameter pipe

at the termination point to accommodate the debris

screen.

3.

Use a sheet metal screw to secure the intake pipe to

the connector, if desired.

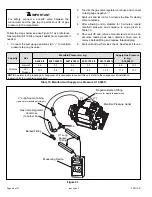

Intake

Debris

Screen

(Provided)

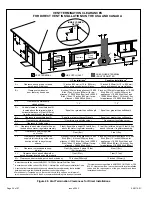

NOTE

: Debris screen and elbow may be rotated so that the

screen may be positioned to face forward or to either side.

Figure 24. Typical Air Intake Pipe Connections

Non-Direct Vent Applications

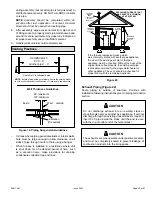

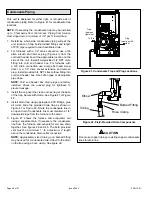

If this unit is being installed in an application with

combustion air coming in from a space serviced by an

exhaust fan, power exhaust fan, or other device which

may create a negative pressure in the space, take care

when sizing the inlet air opening. The inlet air opening

must be sized to accommodate the maximum volume

of exhausted air as well as the maximum volume of

combustion air required for all gas appliances serviced

by this space.

CAUTION

Ventilation Louvers

Inlet Air

(Minimum 12 in.

(305mm) above

Attic Floor)

Roof Terminated

Exhaust Pipe

Furnace

*Intake Debris

Screen

(Provided)

* See Maximum Vent Lengths table

NOTE-The inlet and outlet air openings shall each have a

free area of at least one square inch per 4,000 Btu (645mm

2

per 1.17kW) per hour of the total input rating of all equipment

in the enclosure.

Figure 25.

Equipment in Confined Space

(Inlet Air from Ventilated Attic and Outlet Air to

Outside)