508148-01

Issue 2128

Page 23 of 75

Troubleshooting Motor Windings

Ensure that motor windings are not damaged by performing

the following tests:

NOTE:

If your ohm meter is not an auto-ranging type, set

it to the highest ohm scale (100k ohms or greater) before

performing tests.

Scale

Measurement Range

in Words

in ohms

2 M

two megohm-two million ohms

0 - 2,000,000

200 K

two hundred kilo-ohm-two

hundred thousand ohms

0 - 200,000

20 K

twenty kilo-ohm-twenty thousand

ohms

0 - 20,000

2 K

two kilo-ohm two-thousand ohms 0 - 2,000

200

two hundred ohms

0 - 200

Table 13. Ohm Meter Range

Figure 10.

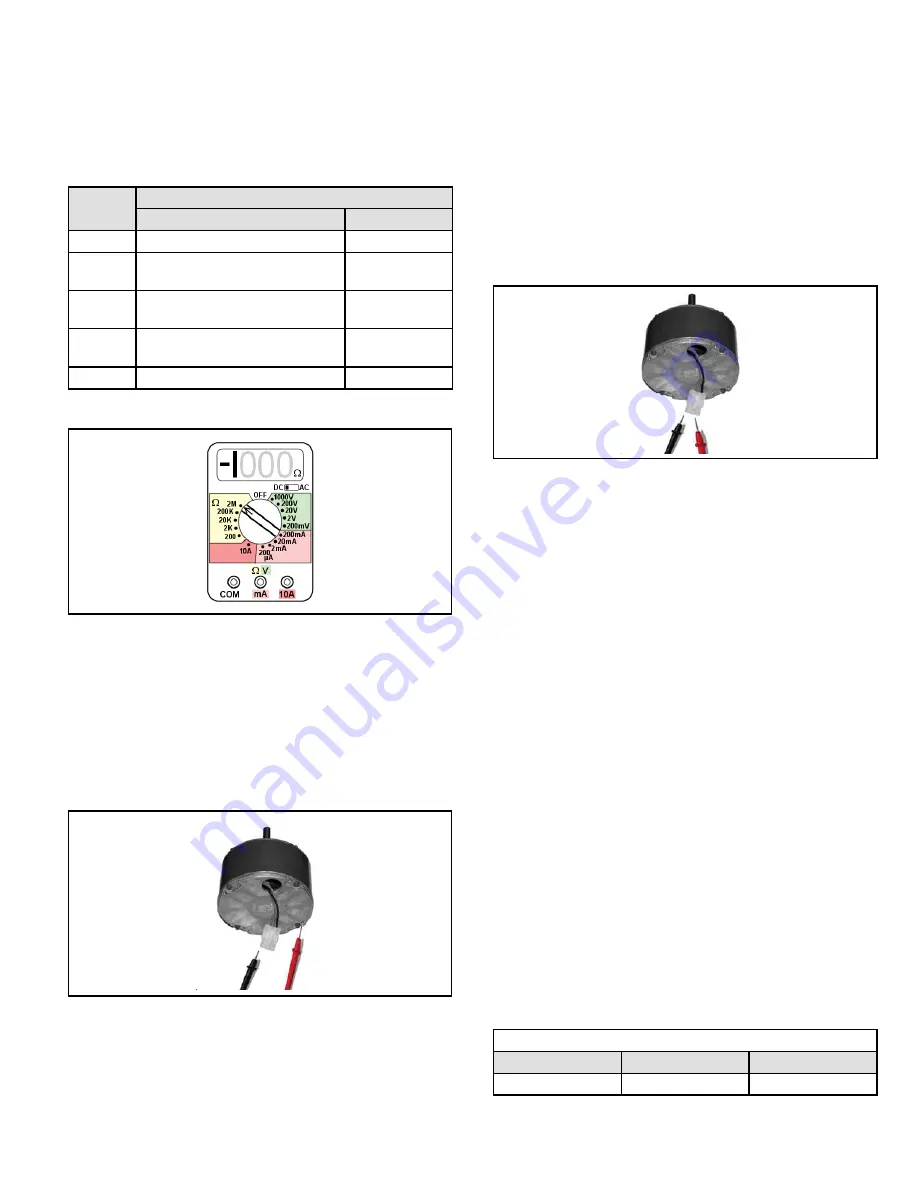

TEST A

Measure the resistance between each of the three motor

leads (3-pin plug) and the unpainted part of the end shield.

If the winding resistance to ground is <100k ohms, replace

the motor and control module. If the resistance to ground

is >100k, the motor windings are fine. Proceed to Test B.

Figure 11. Test A

TEST B

Use an ohmmeter to measure the motor phase-to-phase

resistance by checking these combinations of the the 3-pin

motor plug. For the purpose of this test, start at either end

of the connector as lead 1.

1.

The lead-to-lead resistance across any two leads

should be less than 20 ohms.

2. Each lead-to-lead resistance should be the same.

If the measured resistance is greater than 20 ohms, replace

the motor and control module.

Figure 12. Test B

Heating Components

Ignitor

The ignitor is made of durable silicon nitride. Ignitor

longevity is enhanced by controlling voltage to the ignitor.

The integrated control provides 120 volts to the ignitor for

a consistent ignition. Due to this feature of the control,

voltage measured with a digital meter will be slightly lower.

To measure correct voltage use a true RMS meter or ignitor

can be ohmed. Ohm value should be 39 to 70. See Figure

13 for ignitor location and Figure 15 for ignitor check out.

NOTE:

The A96US2V furnace contains electronic

components that are polarity sensitive. Make sure that the

furnace is wired correctly and is properly grounded.

Flame Sensor

A flame sensor (Figure 13) is located on the left side of

the burner support. The sensor is mounted on the flame

rollout plate and the tip protrudes into the flame envelope

of the left-most burner. The sensor can be removed for

service without removing any part of the burners. During

operation, flame is sensed by current passed through the

flame and sensing electrode. The control allows the gas

valve to remain open as long as flame signal is sensed. To

check flame sense signal use the push-button found on the

integrated control and go to Field Test Mode. The menu

will display the flame signal. See Table 14 for flame signal.

Flame Signal in Microamps

Normal

Low

Drop Out

2.6 or greater

2.5 or less

1.1

Table 14.