508148-01

Issue 2128

Page 34 of 75

Vent Piping Guidelines

NOTE:

Allied Air has approved the use of DuraVent

®

and

Centrotherm manufactured vent pipe and terminations as

an option to PVC. When using the PolyPro

®

by DuraVent

or InnoFlue

®

by Centrotherm venting system the vent

pipe requirements stated in the unit installation instruction

– minimum & maximum vent lengths, termination

clearances, etc. – apply and must be followed. Follow

the instructions provided with PoyPro by DuraVent and

InnoFlue by Centrotherm venting system for assembly

or if requirements are more restrictive. The PolyPro by

Duravent and InnoFlue by Centrotherm venting system

must also follow the uninsulated and unconditioned space

The A96US2V can be installed as either a Non-Direct

Vent or a Direct Vent gas central furnace.

NOTE:

In Non-Direct Vent installations, combustion air

is taken from indoors or ventilated attic or crawlspace

and flue gases are discharged outdoors. In Direct Vent

installations, combustion air is taken from outdoors and

flue gases are discharged outdoors.

Intake and exhaust pipe sizing --

Size pipe according

to Table 18 and Table 19A through Table 19C. Count all

elbows inside and outside the home. Table 18 lists the

minimum vent pipe lengths permitted. Table 19A through

Table 19C lists the maximum pipe lengths permitted.

Regardless of the diameter of pipe used, the standard roof

and wall terminations described in section Exhaust Piping

Terminations should be used. Exhaust vent termination

pipe is sized to optimize the velocity of the exhaust gas as

it exits the termination. Refer to Table 21.

In some applications which permit the use of several

different sizes of vent pipe, a combination vent pipe may

be used. Contact Allied Air Technical Services department

for assistance in sizing vent pipe in these applications.

NOTE:

The exhaust collar on all models is sized to

accommodate 2” Schedule 40 vent pipe. In horizontal

applications, any transition to exhaust pipe larger than 2”

must be made in vertical runs of the pipe. Therefore a 2”

elbow must be added before the pipe is transitioned to

any size larger than 2”. This elbow must be added to the

elbow count used to determine acceptable vent lengths.

Contact the Application Department for more information

concerning sizing of vent systems which include multiple

pipe sizes.

If this unit is being installed in an application with

combustion air coming in from a space serviced by an

exhaust fan, power exhaust fan, or other device which

may create a negative pressure in the space, take care

when sizing the inlet air opening. The inlet air opening

must be sized to accommodate the maximum volume

of exhausted air as well as the maximum volume of

combustion air required for all gas appliances serviced

by this space.

CAUTION

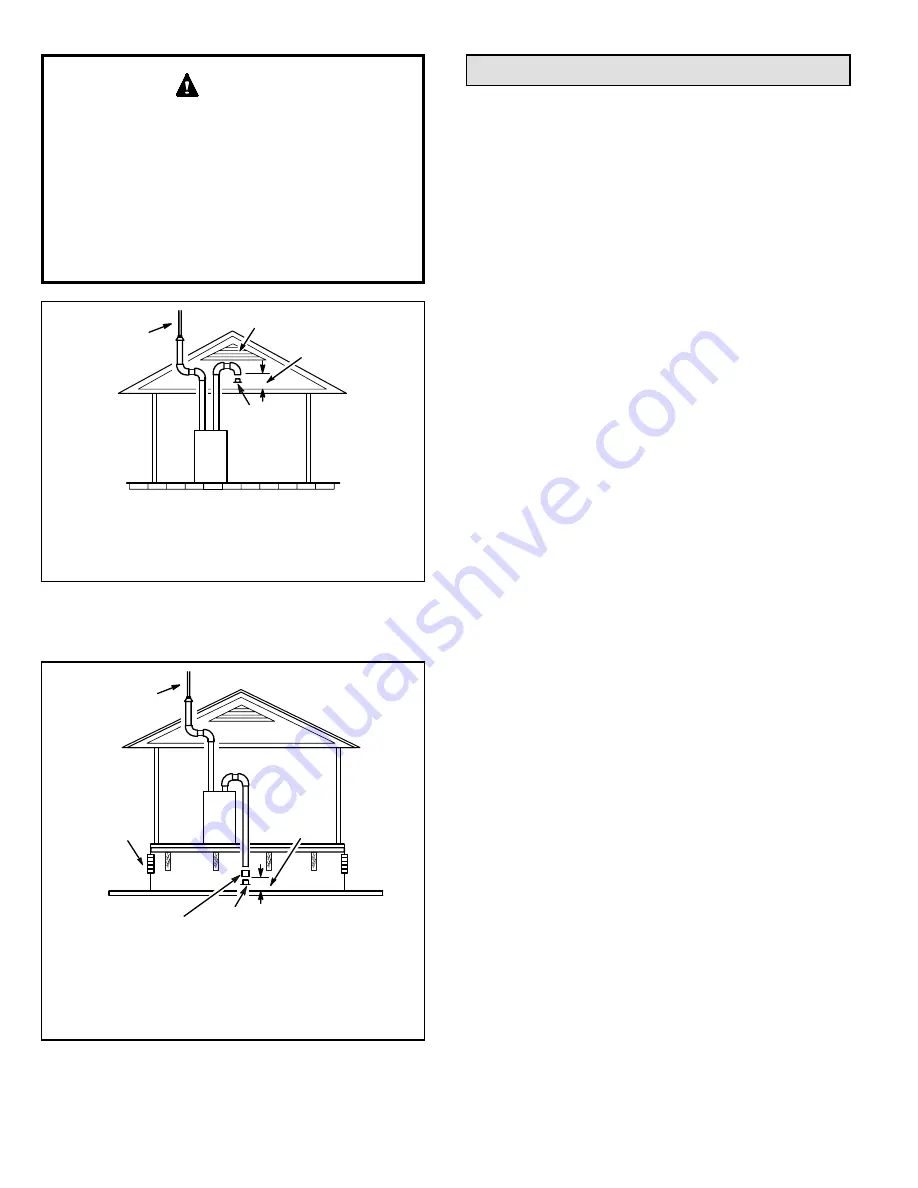

Ventilation Louvers

Inlet Air

(Minimum 12 in.

(305mm) above

Attic Floor)

Roof Terminated

Exhaust Pipe

Furnace

*Intake Debris

Screen

(Provided)

* See Maximum Vent Lengths table

NOTE-The inlet and outlet air openings shall each have a

free area of at least one square inch per 4,000 Btu (645mm

2

per 1.17kW) per hour of the total input rating of all equipment

in the enclosure.

Figure 23.

Equipment in Confined Space

(Inlet Air from Ventilated Attic and Outlet Air to

Outside)

Roof Terminated

Exhaust Pipe

Furnace

Ventilation

Louvers

(Crawl Space)

*Intake Debris Screen Provided

Inlet Air

Minimum

12 in. (305mm)

above Crawl

Space Floor

Coupling or

3 in. to 2 in.

Transition

(Field Provided)

* See Maximum Vent Lengths table

NOTE-The inlet and outlet air openings shall each have a

free area of at least one square inch per 4,000 Btu (645mm

2

per 1.17kW) per hour of the total input rating of all equipment

in the enclosure.

Figure 24.

Equipment in Confined Space

(Inlet Air from Ventilated Crawl Space and Outlet Air

to Outside)