507787-01

Issue 2007

Page 8 of 22

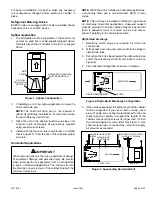

2.

Install properly sized, field-provided connection fittings

and connect primary drain line to the main drain pan

connection.

NOTE:

When installing drain line connection fittings

to the drain pan, hand tighten the fitting and use a

thread sealant. Over-tightening the fittings can split

connections on the drain pan.

3.

If the secondary drain line is to be used, remove the

plug or the knockout and route the drain line so that

water draining from the outlet will be easily noticed

by the homeowner. Refer to local codes for drain trap

requirements on the secondary drain line.

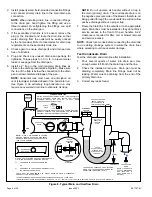

4.

Check again to ensure drain ports and drain pan are

free of all debris.

5.

Plug and check any unused drain pan openings for

tightness. Torque plugs to 30 in. lb. to prevent water

leaks or seepage from the drain pan.

6.

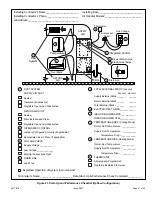

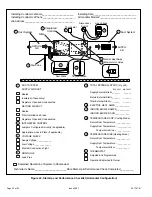

Install a 2” trap in the main (primary) drain lines as

close to the unit as practical (see Figure 8). Make sure

the top of the trap is below the connection to the drain

pan to allow complete drainage of the pan.

NOTE:

Horizontal runs must have an anti-siphon air

vent (standpipe) installed ahead of the horizontal run.

See Figure 8. An extremely long horizontal run may

require an oversized drain line to eliminate air traps.

NOTE:

Do not operate air handler without a trap in

the main (primary) drain. The condensate drain is on

the negative pressure side of the blower; therefore, air

being pulled through the condensate line will not allow

positive drainage without a proper trap.

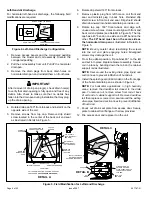

7. Route the drain line to the outside or to an appropriate

drain. Drain lines must be installed so they do not block

service access to the front of the air handler. A 24”

clearance is required for filter, coil, or blower removal

and service access.

NOTE:

Check local codes before connecting the drain line

to an existing drainage system. Insulate the drain lines

where sweating could cause water damage.

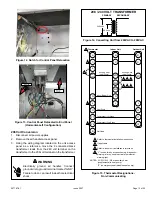

Test Condensate Drain

Test the drain pan and drain line after installation:

1.

Pour several quarts of water into drain pan. Use

enough water to fill both the drain trap and the line.

2.

Check the installed drain pan. Drain pan must be

draining completely. Drain line fittings must not be

leaking. Water must be draining from the end of the

primary drain line.

3.

Correct any leaks found.

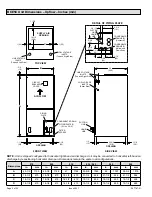

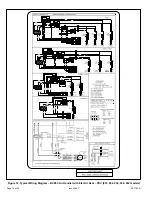

ABOVE

FINISHED

SPACE?

OVERFLOW DRAIN LINE

ALWAYS RUN AN OVERFLOW DRAIN LINE. IF NOT POSSIBLE TO

ROUTE OVERFLOW DRAIN LINE, INSTALL LOW VOLTAGE

OVERFLOW SWITCH KIT. WIRE KIT TO SHUT DOWN

COMPRESSOR PER INSTRUCTIONS.

NO

YES

PART #

X3169

CLEAN OUT

VENT

PRESS IN

(DO NOT GLUE)

VENT MUST EXTEND

ABOVE HEIGHT OF

COIL DRAIN PAN BY

TWO INCHES (51MM)

1” X 3/4” X 3/4”

REDUCING

TEE WITH

PLUG

1

P-TRAP

49P66, J-TRAP #

91P90 OR ANY

PVC SCH 40 P- OR

J-TRAP 3/4”

OVERFLOW

DRAIN

AIR HANDLER DRAIN PAN

WHEN A COIL IS LOCATED ABOVE A FINISHED SPACE, A

3/4” (19.1MM) SECONDARY DRAIN LINE MUST BE:

CONNECTED TO SECONDARY DRAIN PAN

OR

CONNECTED TO THE OVERFLOW DRAIN OUTLET OF

THE AIR HANDLER DRAIN PAN.

TRAPS MUST BE DEEP ENOUGH TO OFFSET MAXIMUM STATIC DIFFERENCES —

GENERALLY, TWO INCHES (51MM).

DRAIN LINE SHOULD

SLOPE A MINIMUM OF

ONE INCH PER 10

FEET (25MM PER 3

METERS)

NOTE

— WHEN A AIR HANDLER IS LOCATED

ABOVE A FINISHED SPACE THE SECONDARY

DRAIN PAN MUST HAVE A LARGER FOOTPRINT

THAN THE AIR HANDLER.

MAIN

DRAIN

TO APPROVED

DRAIN

FOR NEGATIVE PRESSURE COILS (BLOWER

AFTER COIL) TRAPS ARE REQUIRED ON ALL

DRAIN LINES CONNECTED TO COIL.

COMPACT OVERFLOW SWITCH WITH 3/4” FEMALE SLIP INLET

AND MALE ADAPTER, TWO PART DESIGN FOR USE WHERE

OBSTRUCTIONS PREVENT DIRECT THREADING

SECONDARY

DRAIN PAN

2”

(51MM)

TRAP DEPTH

1

P-TRAP 49P66 REQUIRES A LARGER INSTALLATION SPACE THAN THE J-TRAP 91P90.

2

PIPE NIPPLE PROVIDED IN BAG ASSEMBLY - SCH 80, 3/4” I. D. X 5” - 34K7401 (1): CUT THE PIPE IN HALF AND USE IT TO ROUTE THE MA IN DRAIN.

MAIN

DRAIN

PROVIDED

PIPE NIPPLE

2

CUT TO

REQUIRED

LENGTH

SIDE VIEW

Figure 8.

Typical Main and Overflow Drain