507788-01

Issue 2007

Page 3 of 20

Shipping and Packing List

Package 1 of 1 contains:

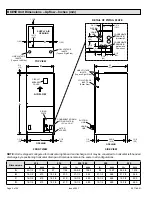

1 – Assembled air handler unit factory-equipped for upflow

or horizontal air discharge application (includes upflow

and horizontal drain pans and pre-installed air filter).

Check the air handler for shipping damage; if found,

immediately contact the last carrier. Check the unit rating

plate to confirm that delivered unit matches order.

General

The BCE5E

series air handler with Omniguard

TM

coil

is designed for indoor installation only. As shipped, the

unit is ready for installation in either upflow or horizontal

right-hand air discharge applications. Horizontal drain

pan may be repositioned in the field to allow installation

in the horizontal left-hand air discharge position. Various

accessories are available and listed in the BCE5E Product

Specification for ordering.

This instruction is intended as a general guide and does

not supersede local or national codes in any way. Consult

authorities having jurisdiction before installation.

NOTE:

Special procedures are required for cleaning

the Omniguard

TM

coil in this unit. See Page 17 in this

instruction for information.

Requirements

Excessive Weight Hazard - Use two or more people

when moving and installing the unit. Failure to do so

can result in back or other type of injury.

WARNING

BCE5E

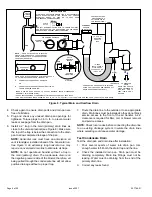

units include a factory-installed check/

expansion valve which will provide optimal refrigerant

control and system performance with outdoor units of

varying capacities. These units must be installed as

a part of a matched system as outlined in the BCE5E

Product Specification.

IMPORTANT

These instructions are intended as a general guide.

Compliance with all local, state, or national codes

pertaining to this type of equipment should be determined

prior to installation. Read this instruction manual, as well

as the instructions supplied in separate equipment, before

starting the installation.

In addition to conforming to manufacturer’s installation

instructions and local municipal building codes, installation

of air handler units (with or without optional electric heat),

MUST conform with National Fire Protection Association

(NFPA) standards: “Standard for Installation of Air

Conditioning and Ventilation Systems” (NFPA No. 90A)

and “Standard for Installation of Residence Type Warm Air

Heating and Air Conditioning Systems” (NFPA No. 90B).

All models are designed for indoor installation only. The

installation of the air handler, field wiring, duct system, etc.

must conform to the requirements of the National Electrical

Code, ANSI/NFPA No. 70 (latest edition) in the United

States, and any state laws, and local ordinances (including

plumbing or waste water codes).

Local authorities having jurisdiction should be consulted

before installation is made. Such applicable regulations

or requirements take precedence over the general

instructions in this manual.

Install the conditioned air plenum, ducts and air filters

(provided) in accordance with NFPA 90B Standard for

the Installation of Warm Air Heating and Air-Conditioning

Systems (latest edition).

The air handler is shipped from the factory completely

assembled. The unit is provided with flanges for the

connection of the duct system.

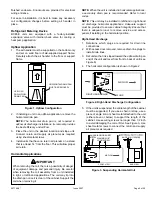

Do not remove the cabinet knockouts until it has been

determined which knockouts will need to be removed for

the installation.

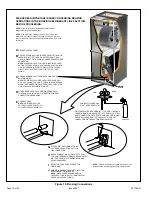

Select the air discharge position which best suits the site

conditions. Consider required clearances, space, routing

requirements for refrigerant line, condensate disposal,

filters, duct system, wiring, and accessibility for service.

Refer to the rating plate on the air handler for specific

information.

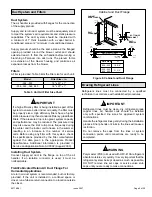

Danger of explosion. Keep flammable

materials and vapors, such as gasoline,

away from air handler. Place air handler so

that heating elements are at least 18 inches

(46 cm) above the floor for a garage

installation. Failure to follow these

instructions can result in death, explosion,

or fire.

WARNING