Page 10 of 16

506941-01

Issue 1148

Continuous Blower

With the proper thermostat and sub-base, continuous blower

operation is possible by closing the R to G circuit.

Heating Sequence of Operation

The following sequence describes the operation of the gas

heat section.

1. A call for heat from the room thermostat starts the

combustion air blower and the circulating air blower.

Cooling System Performance

This equipment is a self contained, factory optimized

refrigerant system, and should require no adjustments

when properly installed. If however, unit performance is

questioned, perform the following checks.

Insure unit is installed per manufacturer’s instructions and

that line voltage and air fl ows are correct. Refer to Table 2

for proper superheat or subcooling values. Check superheat

settings by measuring presure at the suction line service

port. For TXV systems, measure pressure at the liquid

service port. Take line temperature within 2 inches of service

port connection to its main tube. If unit superheat/subcooling

varies by more than table allowance, check internal seals,

service panels and duct work for air leaks, as well as

restrictions and blower speed settings. If unit performance

remains quetionable, remove charge, evacuate to 500

Microns, and weigh in refrigerant to name plate charge. It is

critical that the exact charge is re-installed. Failure to comply

will compromise system performance. If unit performance

is still questionable, check for refrigerant related problems

such as, blocked coil or circuits, malfunctioning metering

devices or other system components.

7. After reassembly of all parts is complete and all wires are

reconnected, open the main manual gas shutoff valve;

check for and correct any gas leaks. Turn electrical

power on, initiate a call for heat, and check for proper

burner operation.

8. Install burner access panel.

Heat Anticipator

The heat anticipator setting is 0.75 amp.

It is important

that the anticipator setpoint be correct. Too high of a setting

will result in longer heat cycles and a greater temperature

swing in the conditioned space. Reducing the value below

the correct setpoint will give shorter “ON” cycles and

may result in the lowering of the temperature within the

conditioned space.

OPERATION

Cooling System

The cooling system is a complete factory package utilizing

an air-cooled condenser and is factory-charged with HFC-

R-410A. The compressor is hermetically sealed and base

mounted with rubber-insulated hold-down bolts.

Cooling Sequence of Operation

When the thermostat calls for cooling, R is closed to G and

Y (see the wiring diagram found on page 13). This action

completes the low voltage control circuit, energizing the

compressor, condenser fan motor, and blower motor.

Unit compressors have internal protection. In the event there

is an abnormal rise in the temperature of the compressor,

the protector will open and cause the compressor to stop.

Blower Delay – Cooling

In cooling mode, the circulating air blower operation is

delayed for fi ve (5) seconds after the compressor starts.

The blower continues to operate for 60 seconds after the

compressor is de-energized. The feature is a function of

the blower motor itself and cannot be changed.

NOTE:

There is no blower OFF delay when there is only

a call for G (fan only).

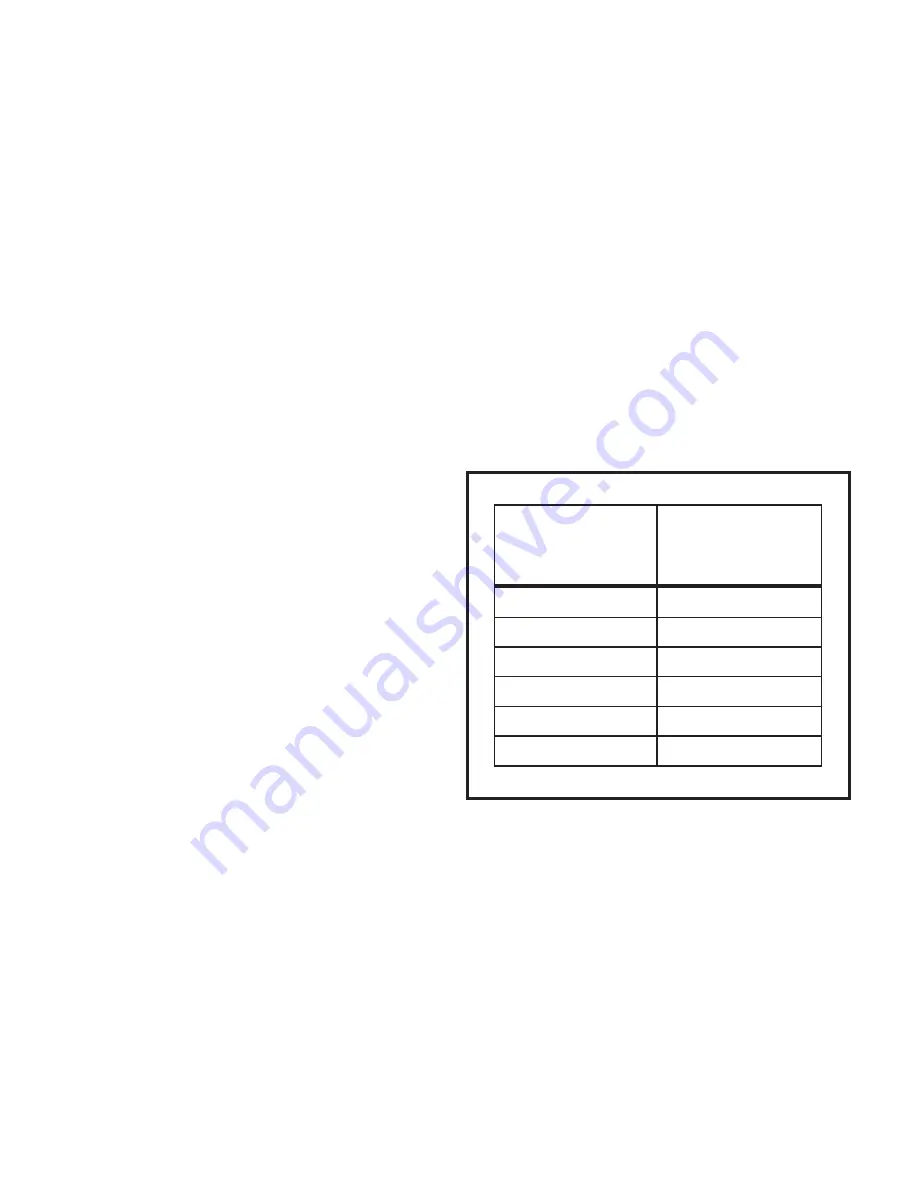

Suction Superheat

Table 2

* This letter will vary according to furnace series.

Outdoor

Unit Model

Suction Superheat

+/- 3° @ ARI

Conditions 82° OD

80° IDDB/67° IDWB

RGE13(*)24

21°

RGE13(*)30

19°

RGE13(*)36

17°

RGE13(*)42

20°

RGE13(*)48

15°

RGE13(*)60

15°