Not for

Reproduction

16 ALLMAND.COM

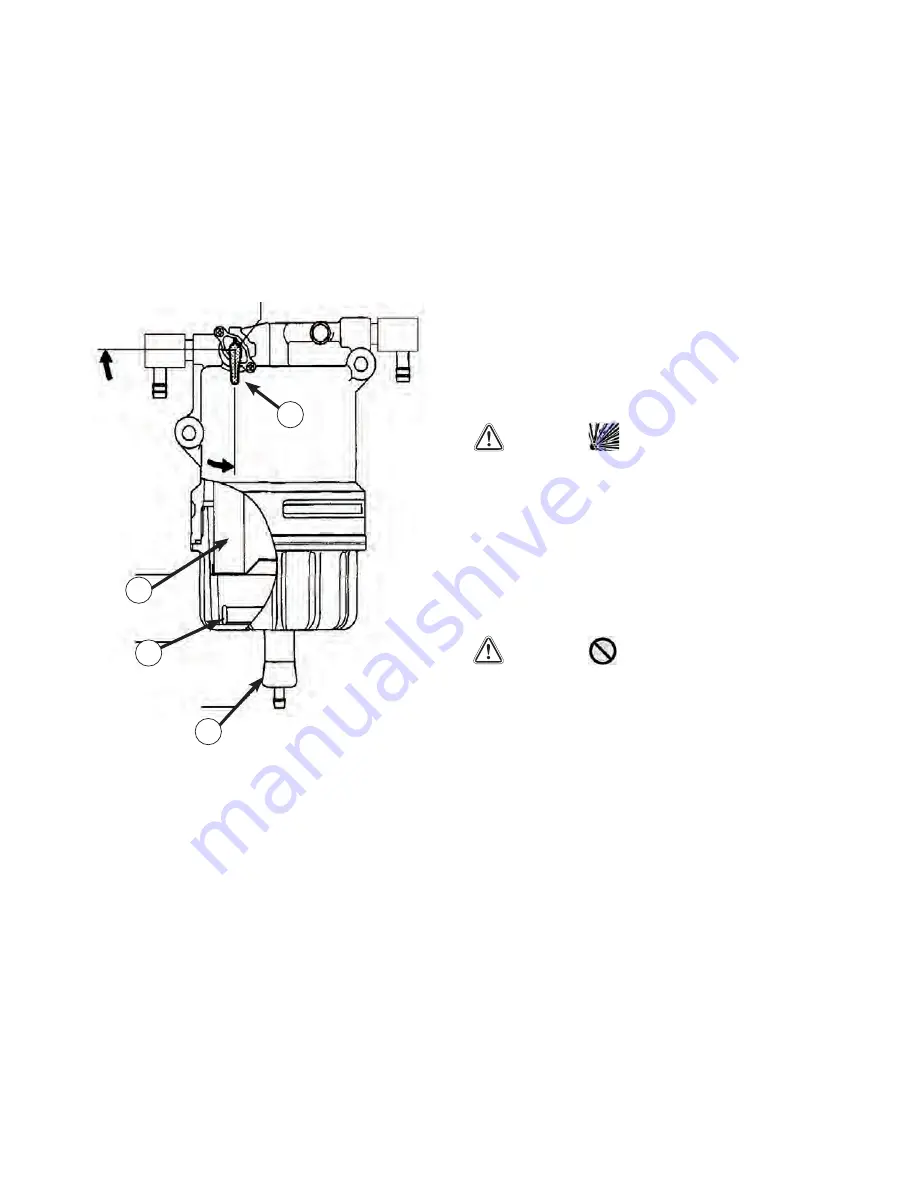

Checking and Draining Pre-Filter for Condensate

1. When red float (

A

) under element (

B

) in Pre- filter

is raised up to upper level, drain water.

2. Turn fuel selector valve (

C

) to OFF position.

3. Loosen the drain valve (

D

) and drain out

condensed water inside.

NOTE:

Make sure to tighten the drain valve

securely, after draining the condensate.

4. Drain the condensate in container and dispose of

condensate according to the local, state and/or

federal regulations.

Checklist Before Starting Engine

Review the unit’s assembly to ensure you have

performed all of the following.

1. Be sure to read

Operator Safety

and

Operation

before operating the comprressor.

2. Make sure compressor is in place and secure.

3. Check that oil has been added to proper level.

4. Check wiring of each part for any loose

connections, damage to insulating sheathed

portion, disconnection, and short circuit.

5. Check piping of each part for any loose

connections, tears, and leaks.

6. Check each hose for tear and leaks.

7. Clean debris from interior of unit. Periodically

check the inside of the unit for debris. Any

flammables such as chips of wood, dead leaves,

and waste paper, especially near the muffler and

exhaust pipe, should be removed.

WARNING

Operation with compressed

air supply port opened is prohibited.

• Do not operate machine with service valves and

relief valve open unless air hoses and/or pipes are

connected. Unregulated, high-pressurized air could

result in serious injury.

• When the machine has to be unavoidably

temporarily operated with its port open, be sure to

mount a silencer to reduce noise and wear personal

protective equipment (PPE) such as earplugs to

prevent hearing damage.

WARNING

• Keep the door closed and locked while running the

unit.

• When the door has to be opened, be careful not to

touch portions that are rotating or very hot. Careless

contact could result in serious injury.

• Pull the handle forward to open the door.

• Be sure to close the door tightly so that it latches

securely.

ON

A

OFF

C

B

D

Summary of Contents for 185 CFM

Page 8: ...N o t f o r R e p r o d u c t i o n 8 ALLMAND COM L B C F A K G E D J H I N M ...

Page 35: ...N o t f o r R e p r o d u c t i o n 35 Data Adjustment Procedure ...

Page 37: ...N o t f o r R e p r o d u c t i o n 37 ...

Page 38: ...N o t f o r R e p r o d u c t i o n 38 ALLMAND COM ...

Page 39: ...N o t f o r R e p r o d u c t i o n 39 Wiring Diagram ...

Page 41: ...N o t f o r R e p r o d u c t i o n 41 Air Piping Compressor Oil Piping ...