43

MAINTENANCE

Keep the lights in proper working order.

Check that all lights operate properly.

Check the trailer lights and harness for

damage or wear and replace as needed.

Ensure the harness is secured into the

trailer and does not hang down onto the

ground.

Check the taillight housing assemblies for

leaks. Use silicone or rubber sealant to seal

the lens or harness or replace the housing

assembly. Dielectric grease will help protect

the sockets and prevent their corrosion.

When replacing bulbs, ensure the proper

bulb is used and use a small amount of Di-

electric grease in the sockets to prevent cor-

rosion.

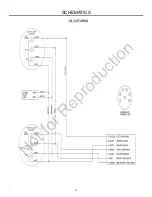

For trailer light wiring schematic information,

See

Tail lamp

wiring schematic on page 50.

LONG TERM STORAGE

Proper maintenance is required when the light

tower and trailer will be stored or removed from

operation for long periods of time.

Refer to the

Engine Operator’s Manual

and the

Generator Operator’s Manual

for all engine and

generator long term storage procedures.

1. Lower the light tower to the full DOWN

position.

2. Make any repairs necessary to ensure the

equipment is fully functional upon

returning the unit back into commission.

3. Clean and wash the frame and body panels.

Apply an anticorrosion coating to all

Surfaces where applicable.

4. Clean any oil or liquid spills inside the

engine compartment.

5. Clean all electrical wiring and components

by hand using a non-corrosive cleaner.

6. Clean the light tower and light fixture

assemblies.

7. Disconnect and remove battery.

8. Use suitable cover to protect the light tower

and trailer.

9. Properly support the trailer axle on jack

stands or other suitable supports to allow

the tires to remain off the ground during

storage.

Always replace bearings and races as a set.

Never mix bearings and races. Bearing part

numbers are sometimes found on the

bearing races; always use the correct

bearing set.

Do not over or under tighten the bearing nut.

Wheel bearings should only be tightened by

hand (spin the wheel while tightening). Back

off the nut to insert the cotter pin. The wheel

should spin freely but without play.

Pack some grease in the inner hub area and

dust cap and ensure the dust cap fits tightly.

Trailer Lighting

Not

for

Reproduction

Summary of Contents for MAXI-LITE AS3000

Page 46: ...46 MAINTENANCE RECORD DATE SERVICE DESCRIPTION SERVICED BY N o t f o r R e p r o d u c t i o n...

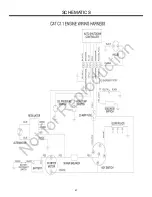

Page 47: ...47 SCHEMATICS N o t f o r R e p r o d u c t i o n...

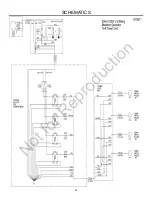

Page 48: ...48 SCHEMATICS N o t f o r R e p r o d u c t i o n...

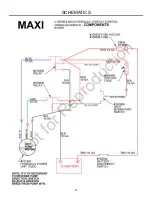

Page 49: ...49 SCHEMATICS N o t f o r R e p r o d u c t i o n...

Page 50: ...50 SCHEMATICS N o t f o r R e p r o d u c t i o n...

Page 51: ...51 SCHEMATICS N o t f o r R e p r o d u c t i o n...

Page 52: ...52 WARRANTY N o t f o r R e p r o d u c t i o n...

Page 53: ...53 WARRANTY N o t f o r R e p r o d u c t i o n...