English -

11

6-1624982 - rev.3 - 03/11/2021

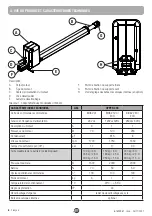

6. INSTALLATION

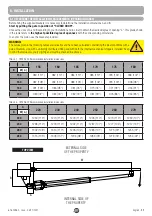

6.1 DETERMINE THE INSTALLATION MEASUREMENTS (OPENING INWARDS)

Before fixing the supplied brackets it is necessary to determine the installation dimensions A and B.

Start by putting the gate in position of "CLOSED DOOR".

Choose the sizes of A and B according to your installation and in order to obtain the desired degree of opening "α". This grade shown

in the table refers to

the highest possible degree of openness

with the corresponding dimensions.

To anchor the piston use the brackets provided.

TABLE 7 - HYPER 400 Recommended installation dimensions

A

155

160

165

170

175

180

B

W ( α )

150

980 (110°)

982 (110°)

984 (110°)

985 (110°)

973 (104°)

968 (102°)

160

987 (108°)

992 (110°)

983 (105°)

978 (102°)

973 (100°)

968 (98°)

180

991 (100°)

986 (98°)

981 (96°)

976 (94°)

971 (93°)

966 (91°)

200

989 (92°)

984 (90°)

982 (90°)

981 (90°)

976 (88°)

964 (85°)

TABLE 8 - HYPER 600 Recommended installation dimensions

A

220

230

240

250

260

270

B

W ( α )

220

1269 (110°)

1270 (110°)

1273 (110°)

1278 (110°)

1279 (110°)

1269 (107°)

240

1288 (110°)

1290 (110°)

1292 (110°)

1287 (107°)

1277 (104°)

1267 (101°)

260

1302 (108°)

1310 (110°)

1295 (104°)

1285 (101°)

1275 (99°)

1265 (97°)

280

1313 (105°)

1303 (101°)

1293 (98°)

1283 (96°)

1273 (94°)

1263 (92°)

A

B

W

TOP VIEW

INTERNAL SIDE OF

THE PROPERTY

EXTERNAL SIDE

OF THE PROPERTY

WARNING!

The values given in the following tables are indicative and have been calculated considering the ideal conditions with a

gate of medium size, with a uniformly distributed filling and with both the internal mechanical stoppers installed. Keep

in mind that values may vary slightly and must be checked in advance.