20

ENGLISH

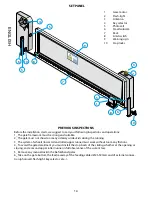

MAINTENANCE

DANGER:

For any kind of maintenance, disconnect the power supply.

The reduction grease is supplied with permanent lubrication grease and therefore does not require main-

tenance.

For the correct maintenance of the system where the reduction gear is operative, proceed as follows:

Clean and clear from debris periodically the rail and its wheels.

In the event of malfunction, the system must not be used.

Contact specialized personnel.

DISPOSAL

Dispose of materials in compliance with current standards

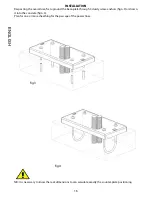

GENERAL WARNINGS

Attach labels that warn against crushing in a highly visible place or near the fixed controls;

•

Permanently attach the labels concerning manual release and place them near the manoeuvre

device;

•

Markings must be visible even after the device has been installed. If markings are hidden after

installation, this must be indicated in the instructions.

•

The movement motors must be provided with a label that instructs to keep children away from

the moving door, or place the appropriate symbol (ISO 3864, see symbol)

FINAL RECOMMENDATIONS

Keep the remote control out of the reach of children and do not let them play with the control devices.

•

Supply the system with security systems such as photocells, sensitive frame, torque limiter. When

the system is in proximity of a public street it is necessary to install at least two of the aforementioned

devices (choose among three types or even of the same type).

•

Realize the system in compliance with current standards.

•

Always keep the supply cables separate from the control cables.

•

Carry out grounding.

•

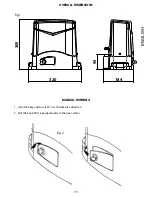

It is absolutely necessary for the door to be provided with check stops prior to installation of the

reduction gear.

•

In order to unlock it is necessary for the gate, once it is closed, not to push on the stop bead.

•

Control over the thrust force must be given by a torque limiter in the system.

•

All maintenance, repair and adjustment must be carried out by qualified personnel.

•

Motors with pressure-sensitive systems must be equipped with a label that says

ATTENTION: RISK OF CRUSHING.