12

ENGLISH

INDEX

IMPORTANT REMARKS 12

MODELS AND FEATURES

13

TECHNICAL DATA 13

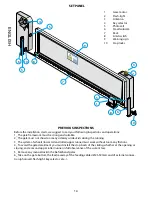

SET PANEL 14

PREVIOUS INSPECTIONS 14

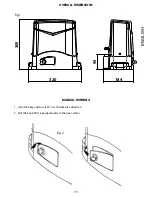

OVERALL DIMENSIONS 15

MANUAL RUNNING 15

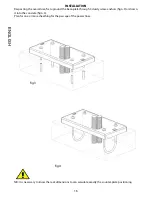

INSTALLATION 16

FIXING 17

RACK ASSEMBLING 18

LIMIT SWITCH FIXING 19

MAINTENANCE

20

DISPOSAL

20

INDEX

IMPORTANT REMARKS

For any installation problems please contact

Allmatic S.r.l. TEL. (+39) 0437 751175

has the right to modify the product without previous notice; it also declines any responsibility to damage or injury to

people or things caused by improper use or wrong installation.

Please read this instruction manual very carefully before installing and programming your control unit.

• This instruction manual is only for qualified technicians, who specialize in installations and automations.

• The contents of this instruction manual do not concern the end user.

• Every programming and/or every maintenance service should be done only by qualified technicians.

AUTOMATION MUST BE IMPLEMENTED IN COMPLIANCE WITH THE EUROPEAN REGULATIONS IN FORCE:

EN 60204-1

(Machinery safety. electrical equipment of machines, part 1: general rules)

EN 12445

(Safe use of automated locking devices, test methods)

EN 12453

(Safe use of automated locking devices, requirements)

• The installer must provide for a device (es. magnetotermical switch) ensuring the omnipolar sectioning of the

equipment from the power supply.

The standards require a separation of the contacts of at least 3 mm in each pole (EN 60335-1).

• The plastic case has an IP55 insulation; to connect flexible or rigid pipes, use pipefittings having the same insulation

level.

• Installation requires mechanical and electrical skills, therefore it shall be carried out by qualified personnel only, who

can issue the Compliance Certificate concerning the whole installation (Machine Directive 2006/42/CEE, Annex IIA).

• The automated vehicular gates shall comply with the following rules: EN 13241-1, EN 12453, EN 12445 as well as any

local rule in force.

• Also the automation upstream electric system shall comply with the laws and rules in force and be car-

ried out workmanlike.

• The door thrust force adjustment shall be measured by means of a proper tool and adjusted according to

the max. limits, which EN 12453 allows.

• We recommend to make use of an emergency button, to be installed by the automation (connected to

the control unit STOP input) so that the gate may be immediately stopped

in case of danger.

• The appliance is not to be used by children or persons with reduced physical, sensory or mental capabili-

ties, or lack of experience and knowledge, unless they have been given supervision or instruction.

• Children being supervised do not play with the appliance.