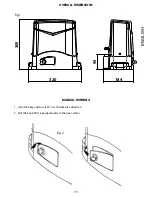

2mm

89mm

89mm

25mm

90mm

18

ENGLISH

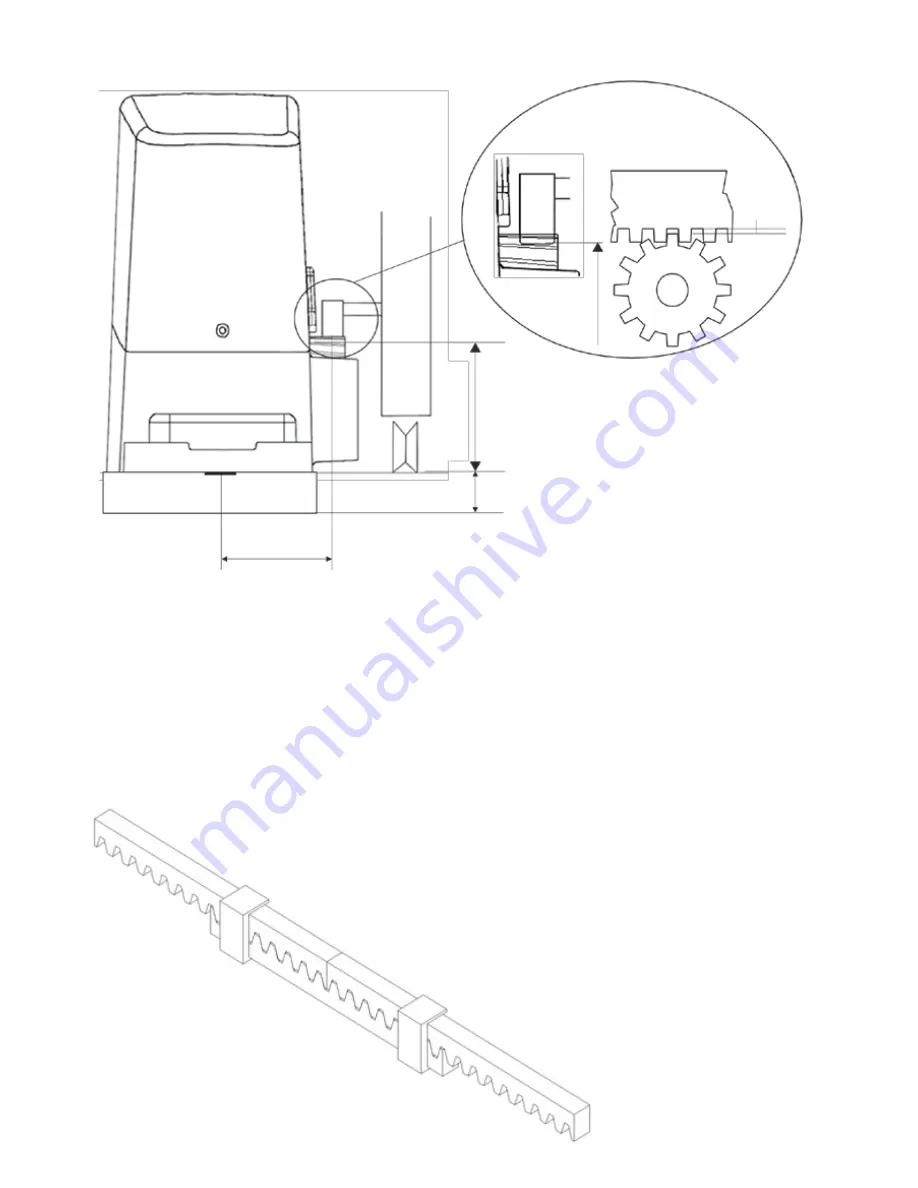

RACK ASSEMBLING

Release the gear-motor as indicated by the fig.1/2 and open entirely the gate. Put a rack element on the

pinion gear and fasten it to the gate with screw and spacing bars.

Move the gate manually bringing the pinion gear into line with the last spacing bar.

Fasten the rack element for good.

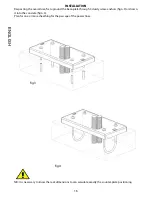

For a correct positioning of the other elements and to assure

their straightness, it is necessary to employ a rack

element using it as support and reference (fig.9).

It is besides necessary to assure an aperture of 2 mm between

rack and pinion gear, so that the gate weight doesn’t rest on the

gear-motor pinion gear (as shown in the fig.8).

fig.8

fig.9