10

C:

INSTALLING THE OPERATOR

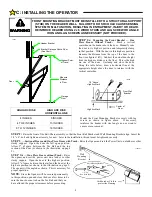

Step 8: Connecting Door Arm to Trolley

(THIS IS FOR SECTIONAL DOORS ONLY - FOR ONE

PIECE DOORS PROCEED TO STEP 10)

The door arm assembly consists of the door arm tube section and door arm

rod which are packaged separately. To assemble, screw the door arm rod into

the the door arm tube in a clockwise direction approximately ten turns.

Connect the door arm assembly into the trolley with the open end of the rod

hook facing the power head unit (away from the door). Extend the manual

release cord (connected to the trolley) and thread through the warning tag and

red pull knob handle. Adjust so the knob is 6 feet above the floor and secure

with a double overhand knot in the end of the release cord.

Release the trolley (leave door arm attached) with the manual release cord

and pull trolley toward the door.

110053-2

Trolley

(Close Limit Position)

Cushion

Arm

Assembly

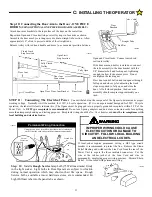

Step 9: Connecting the Door Arm to the Door

Type 1: Door Mounted Bracket

Visually align the door arm connecting hole with the middle hole of

the door bracket by rotating the tube section in the appropriate

direction.

Release the trolley (leave door arm attached) with the manual release

cord and pull trolley toward the power head unit. Now rotate the door

arm tube section two turns counterclockwise (increasing the exposed

length of the door rod) to provide a cushion when the door is closed or

encounters an obstruction. Align connecting hole in the door arm to

middle hole in the door bracket; insert 3/8” diameter bolt and tighten

locking nut, allowing for free pivot of the arm.

Note: Do not

overtighten locking nut as this will cause binding between the door

arm and door bracket.

110054-2

Type 2: Strut Mounted Bracket

Visually align the door arm connecting hole with the connecting

pin of the strut by rotating the tube section in the appropriate

direction.

Release the trolley (leave door arm attached) with the manual

release cord and pull trolley toward the power head unit. Now

rotate the door arm tube section two turns counterclockwise

(increasing the exposed length of the door rod) to provide a cushion

when the door is closed or encounters an obstruction. Align

connecting hole in the door arm with the strut mounted connecting

bracket. Insert connecting pin through the hole in the door arm.

Secure the connecting pin to the strut bracket according to the

manufacturer’s instructions.

Note: Door Bracket Mount or Strut Mount - If rod

bottoms in cushion tube, cut rod to allow for proper

function of this assembly.

Alternate Strut

Connecting Bracket

Cut to Fit

110054-2