14

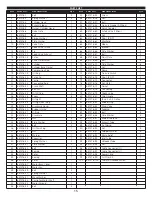

TROUBLESHOOTING GUIDE

Problem Encountered

Possible Cause

Possible Solution

Air continues to leak at

motor/pressure switch release

valve while motor is running:

Defective motor/pressure switch.

Replace.

Check valve stuck in open position.

Replace check valve.

DANGER —

Do not disassemble the

check valve with tank pressurized. Open tank petcock valve

to allow air to escape from tank prior to servicing.

Air leaks from safety relief

valve:

Possible defective safety relief valve.

Operate safety relief valve manually by pulling on ring. If it

still leaks, it should be replaced.

Excessive tank pressure.

Defective motor/pressure switch. Replace.

Air leaks at pump:

Blown gaskets.

Replace blown gaskets and torque head bolts to 20 ft./lbs.

CAUTION —

Replace head gasket with a new one each time

the head is removed to ensure proper sealing.

Air leaks at fittings:

Fittings are not tight enough.

Tighten fittings where air can be heard escaping. Check

fittings with soapy water solution. DO NOT OVERTIGHTEN.

Air leaks in air tank:

Defective or rusted air tank.

Air tank must be replaced. DO NOT ATTEMPT TO REPAIR

AIR TANK!

Air blowing from inlet filter:

Damaged inlet (reed) valve.

Contact Consumer Helpline at 1-800-423-3598.

Insufficient pressure at air tool

or air accessory:

Pressure regulator knob is not turned

to high enough pressure.

Adjust pressure regulator knob to proper setting.

Defective motor/pressure regulator

switch.

Replace.

Restricted air intake filter.

Clean or replace the filter element.

Air leaks.

Check for leaks by applying soap solution to all fittings and

connections. Bubbles will appear at leakage points. Tighen or

replace leaking fittings or connections as needed.

Hose or hose connections are too

small or long.

Replace with larger hose or connectors.

Air compressor is not large enough for

air requirement.

Check the accessory air requirement. If it is higher than the

CFM or pressure supply of the air compressor, you need a

larger air compressor.

Air compressor not making

enough air:

Restricted air intake filter.

Clean or replace the filter element.

Leaking (reed) valve.

Drain air tank and measure pump up time. Compare to

specifications. If lower, remove pump head and inspect valve

plate, valve seats, and valve reeds. Clean or replace as needed.

Restricted pilot valve.

Clean or replace.

Low compression.

Low pressure may be due to worn piston rings and cylinder

walls. Inspect for excessive wear and replace worn parts as

needed.

Excessive oil consumption:

Restricted air intake filter.

Clean or replace air filter element.

Air compressor on unlevel surface.

Do not incline the air compressor more than 10 degrees in

any direction while running.

Crankcase overfilled with oil.

Drain oil. Refill to proper level with 30 weight non-detergent

air compressor oil

Plugged oil dipstick vent.

Clean and check breather for proper ventilation.

Oil leaks.

Repair.

Worn piston rings or scored cylinder.

Replace worn or damaged parts as needed.

Improper oil viscosity.

Drain oil. Refill to proper level with 30 weight non-detergent

air compressor oil.

Oil has milky appearance:

Water in oil due to condensation.

Change oil and move air compressor to a less humid

environment.

Moisture in discharge air:

Condensation in air tank caused by

high level of atmospheric humidity or

air compressor is not running long

enough.

Drain tank after every use. Drain air tank more often in

humid weather and use an air line filter.