RISK OF FALLING

Portable air compressors can fall from a table, workbench, or roof causing damage to the compressor and could result in serious injury or

death to the operator. Always operate air compressor in a stable and secure position to prevent accidental movement of the unit. Never

operate air compressor on a roof or other elevated position. Use additional air hose to reach high locations.

RISK OF PROPERTY DAMAGE WHEN TRANSPORTING COMPRESSOR

Oil can leak or spill and could result in fire or breathing hazard, serious injury or death. Oil leaks will damage carpet, paint, or other surfaces

in vehicles or trailers.

AIR TOOLS AND ACCESSORIES

Do not exceed the pressure rating of any air tools, spray guns, air accessories, or inflatables. Excess pressure can cause them to explode,

resulting in serious injury. Follow the manufacturers recommended pressure settings for all air tools and air accessories.

INSTALLATION AND LOCATION

In order to avoid damaging the air compressor, do not allow the unit to be tilted more than 10º from the normal horizontal position when

operating.

The compressor must be run with the rubber feet resting on a flat and stable horizontal surface.

The air compressor must be used in a clean and well-ventilated area. The compressor requires an unobstructed airflow and must be located a

minimum of 20 inches from any walls or other obstructions that may prevent proper ventilation. DO NOT place air compressor in an area:

• Where there is evidence of oil or gas leaks.

• Where flammable gas vapors or materials may be present.

• Where air temperatures fall below 32ºF or exceed 104ºF.

• Where extremely dirty air or water could be drawn into the air compressor.

SERIOUS INJURY OR DEATH MAY OCCUR IF ELECTRICAL SPARKS FROM MOTOR AND PRESSURE SWITCH COME IN CONTACT

WITH FLAMMABLE VAPORS, COMBUSTIBLE DUST, GASES OR OTHER COMBUSTIBLE MATERIALS. WHEN USING THE

AIR COMPRESSOR FOR SPRAYING PAINT, PLACE THE AIR COMPRESSOR AS FAR AWAY FROM THE WORK AREA AS POSSIBLE,

USING EXTRA LENGTHS OF AIR HOSE TO EXTEND THE WORKING REACH INSTEAD OF EXTENSION CORDS.

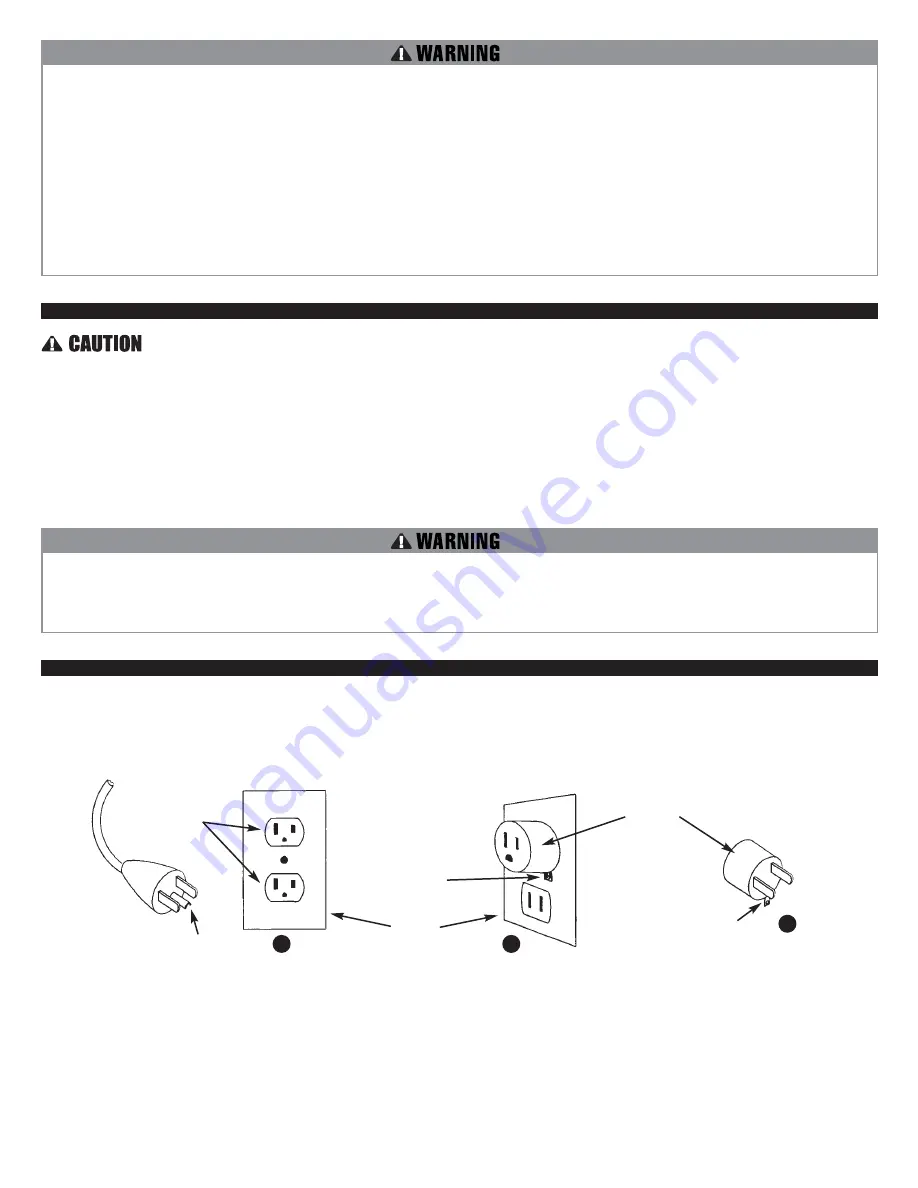

GROUNDING INSTRUCTIONS

This product should be grounded. In the event of an electrical short circuit, grounding reduces the risk of electric shock by providing an escape

wire for the electric current. This product is equipped with a cord having a grounding wire with an appropriate grounding plug. The plug must

be plugged into an outlet that is properly installed and grounded in accordance with all local codes and ordinances.

5

Figure 1 Grounding Method

Grounding Pin

Grounded

Outlet

Cover of

Grounded Outlet Box

Metal Screw

A

B

Tab for Grounding

Screw

C

ADAPTER