SHUTDOWN AND STORAGE:

NOTE:

NEVER stop the air compressor by unplugging it from the power outlet as this may result in damage to the compressor.

1. Turn the switch to the OFF position

2. Disconnect the power cord from the power outlet by grabbing the plug (not the cord). Loop around handle for storage.

3. Turn the pressure regulator knob fully counterclockwise to close airflow from air outlet port. Check the outlet pressure gauge to ensure that

it reads 0 PSI.

4. Remove the air hose and any air accessories.

5. Drain moisture from the air tank by slowly opening the air tank drain valve by turning clockwise. Tilt tank to remove all moisture. Once all

the moisture has drained out, close the fitting securely.

6. Allow the compressor to cool down.

7. Wipe the air compressor clean and store it in a clean, dry, and non-freezing location.

WHEN PERFORMING ANY MAINTENANCE OR SERVICE:

1. The air compressor must be turned off.

2. Disconnect compressor from the power source.

3. Open tank drain to bleed off all air pressure before attempting any maintenance or repair.

4. Allow compressor to fully cool before attempting any maintenance or repair.

Check the air compressor frequently for any visible problems and follow maintenance procedures each time the compressor is used.

All air compressors contain maintenance parts that require periodic replacement. These used parts, including air filters and used lubricating oil,

may contain regulated substances that must be disposed of in accordance with local, state, and federal laws and regulations.

1. Turn compressor off and release pressure from the system. Drain moisture from the air tank by slowly opening the air tank drain valve by

turning clockwise. Tilt tank to remove all moisture. Once all the moisture has drained out, close the fitting securely.

2. Wipe the compressor clean.

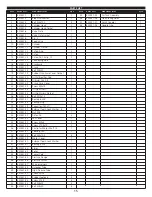

MAINTENANCE CHECKLIST:

Daily:

• Check oil level.

• Drain accumulated liquid from tank.

• Check for oil leaks.

• Check for unusual noise and/or vibrations.

• Check that all fasteners are secure.

• Wipe compressor clean.

+ Apply a solution of soapy water around joints. Look for air bubbles around joints when compressor reaches the pressure cut-out limit and the

pump turns off.

* The pump oil must be changed after the first 20 hours of operation. Thereafter, change oil every 200 hours of operation or every six months,

whichever comes first. In harsh operating conditions, maintenance must be performed more frequently.

OIL CHANGE:

Used lubricating oil may contain regulated substances that must be disposed of in accordance with local, state, and federal laws and regulations.

1. The air compressor must be turned OFF.

2. Allow compressor to fully cool before attempting any maintenance or repair.

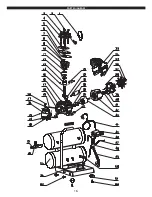

3. Place a suitable oil drain pan below oil drain plug (see Fig. 4).

4. Remove oil fill breather plug to allow air to enter crankcase.

5. Remove oil drain plug.

6. Allow oil to drain completely. Tilt air compressor towards the oil drain to assist draining.

7. Clean and replace oil drain plug.

8. Refill crankcase with SAE 30 weight non-detergent air compressor oil until the oil level

reaches the center of the red circle in the oil level sight glass. Be careful not to overfill.

9. Reinstall the oil fill breather plug.

11

Weekly:

• Inspect and clean air filter.

• Clean breather holes on oil fill plug.

Monthly:

• Check for air leaks.+

• Check safety relief valve.

Six months or 200 operating hours:

*

• Change compressor oil. Use only SAE

30 weight non-detergent air

compressor oil.

• Replace oil more frequently when

used in dusty operating environments.

Fig. 4