MANUALE PREPARATORE A DENTI CA - CB - CC

Old Cod.Q00A00155

New Cod. MANT2010/00751 R.0

GENERAL INFORMATION

- 2

Copyright ©2009 della Alpego spa ® -Tutti i diritti sono riservati. È espressamente vietata la ristampa o l’uso non autorizzato per iscritto da parte di Alpego spa

5.11. STORAGE ........................................................................................................................................................ 30

6. MAINTENACE .......................................................................................................................................................... 31

6.1. INSPECTIONS AND CHECK-UP ...................................................................................................................... 31

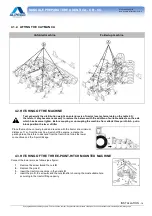

6.2. REPLACEMENT OF THE WORKING TOOLS .................................................................................................. 31

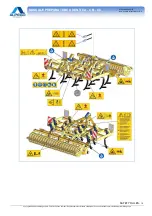

6.2.1. PLAN FOR THE ASSEMBLY OF THE CONVEYING TOOLS.................................................................... 32

6.3. LUBRIFICATION ................................................................................................................................................ 33

6.1. LUBRIFICATION CHART .................................................................................................................................. 33

6.2. LUBRICANT TO BE USED ................................................................................................................................ 34

7. OPTIONS .................................................................................................................................................................. 34