6 - MAINTENANCE

6.1 CHECKS AND CONTROLS

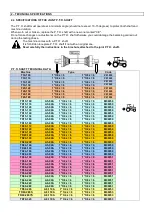

During the first 8 hours of use, it is important to check the tightness of all the bolts since the effort during working

procedures creates a settlement of the whole structure. This control should be done every 50 working hours and the

instructions of the following chart should be followed.

M 8

M 10

M 12

M 14

M16

M18

M20

M 22

M 24

13

17

19

22

24

27

30

32

36

Tightening couple Kgm

3

6

10

14

21

24

40

54

70

Tightening couple Nm

30

59

98

137

205

250

390

530

685

6.2 SIDE TRANSMISSION

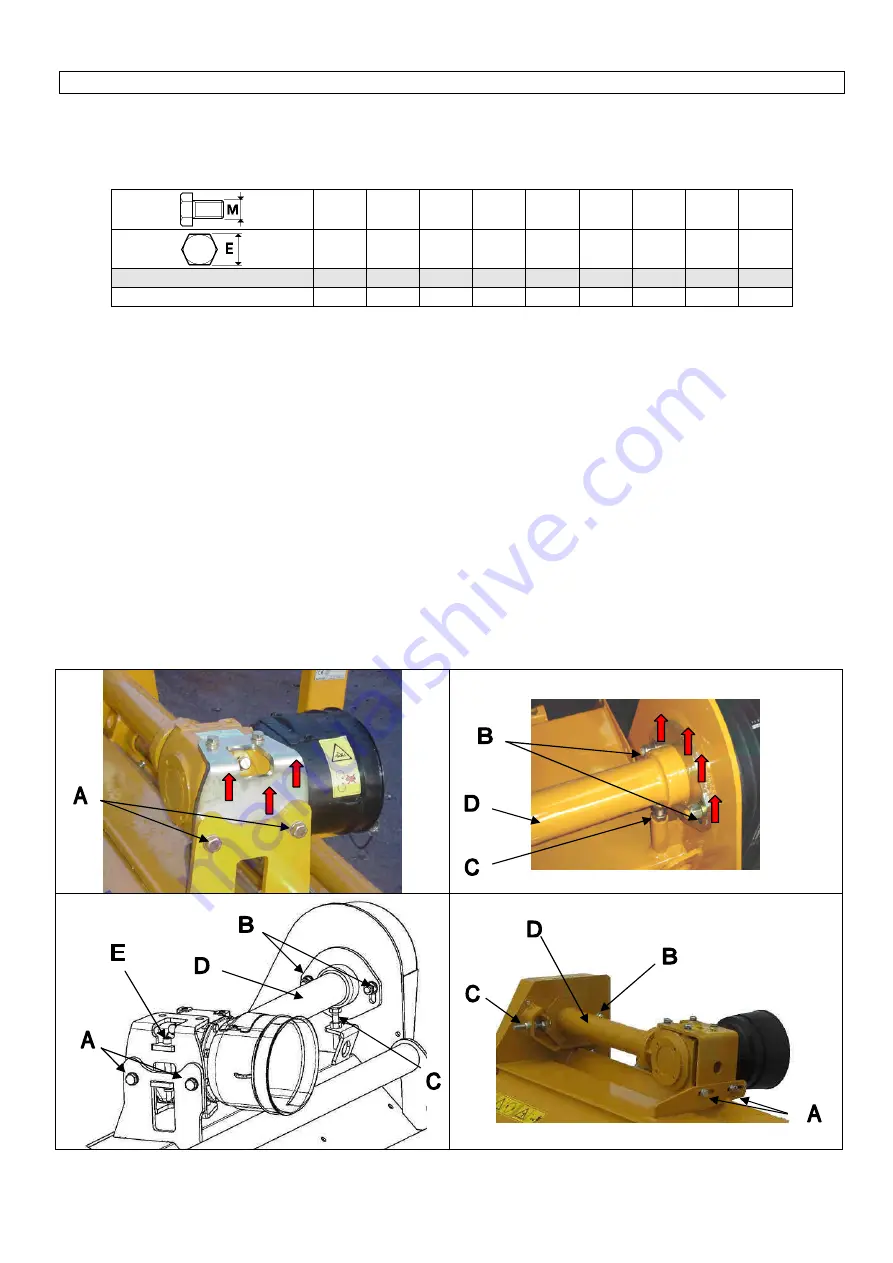

The engine power is transmitted to the rotor by means of belts with an adjustable pulley.

The tension of these belts should be checked periodically to avoid bad functioning or slipping of these transmission

belts

Tension of transmission belts

When checking the tension of the transmission belts the tractor must be turned off :

- remove the bolts which are fixed to protection carter, open the carter pulling it outwards;

- to check the tension, you have to press strongly, with a weight of 6 kg on the belt; in the middle part between the two

pulleys, to make a slight change on the single belt’s shape of about 1 cm.

- loosen the bolts keeping the overdrive/multiplier attached to the structure;

- adjust the two bolts until the belts have the correct tension;

- when belts are in tension, check alignment of pulleys;

- fasten properly all the previously loosened bolts;

- reassemble the carter

Belts must be checked regularly: after the first 2 working hours and subsequently every 8 working hours. This check

must be carried out in case of excessive slipping, and smoke coming out of the protection bonnet.

To guarantee a uniform tension and a correct distribution of forces, it is also necessary to replace all the belts even if

only one of them is damaged.

Summary of Contents for T10 Series

Page 31: ...6 MAINTENANCE ...