___________________________________________________________________

Alpha ESS Co., Ltd.

Page 63

Your Smart Energy

Routine Maintenance

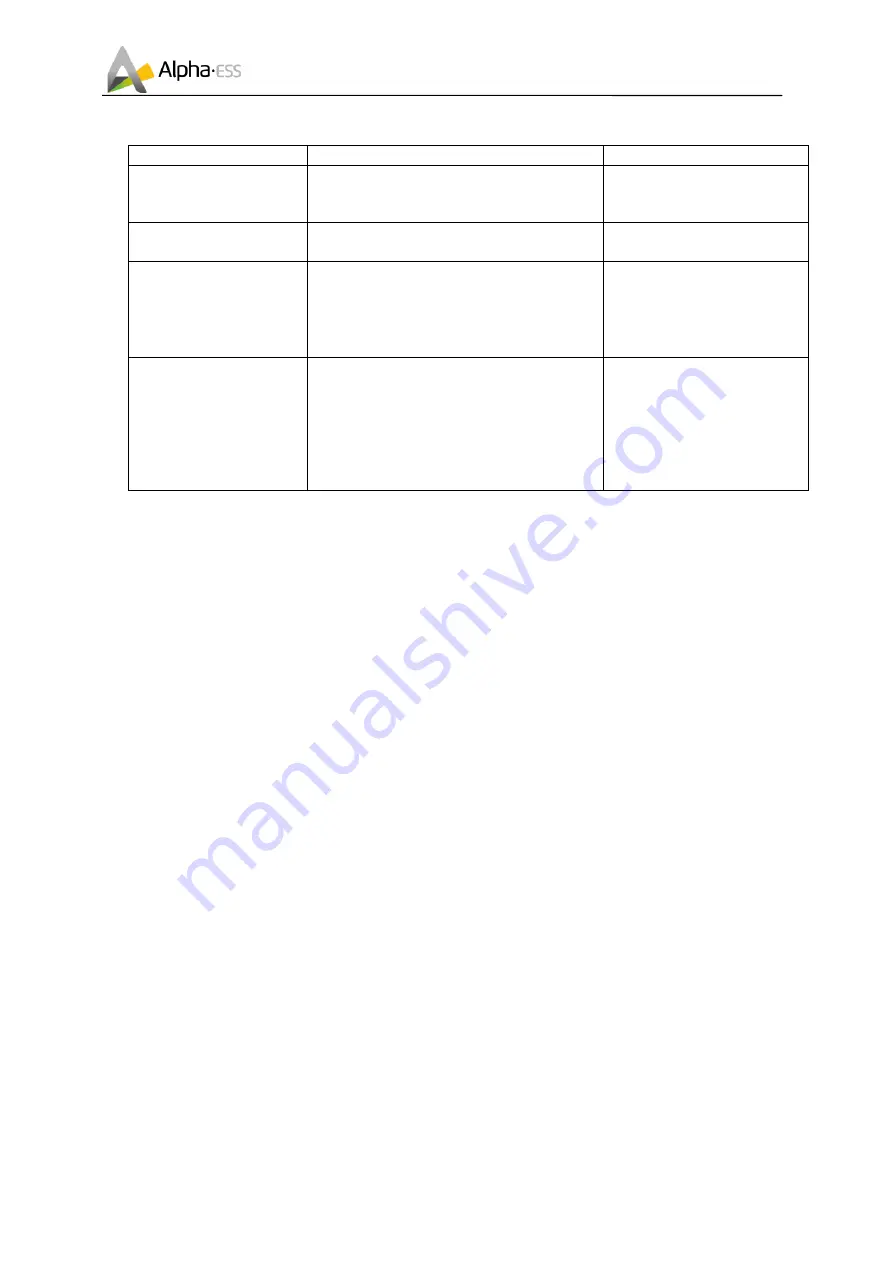

Check Item

Acceptance Criteria

Maintenance Interval

Product

cleanliness

The heatsink at the back of SMILE-

B3-PLUS are free from obstacles or

dust.

Once every 6 to 12

months

Product visible

damage

The SMILE-B3-PLUS are not

damaged or deformed.

Once every 6 months

Product running

status

1. SMILE-B3-PLUS operate with no

abnormal sound.

2. All parameters of SMILE-B3-PLUS

are correctly set. Perform this check

when SMILE-B3-PLUS is running.

Once every 6 months

Electrical

connections

1. Cables are securely connected.

2. Cables are intact, and in particular,

the cable jackets touching the metallic

surface are not scratched.

3. Unused cable glands are blocked

by rubber sealing which are secured

by pressure caps.

Perform the first mainte-

nance 6 months after the

initial commissioning.

From then on, perform

the maintenance once

every 6 to 12 months.

6.1.1

Operating Environment

(Every half year)

Carefully observe whether the battery system equipment is ineffective or damaged;

When the system is running, listen to any part of the system for abnormal noise;

Check whether the voltage, temperature and other parameters of the battery and other equipment

parameters are normal during system operation;

6.1.2

Equipment Cleaning

(Every six months to one year, depending on the site environment and dust content, etc.)

Ensure that the ground is clean and tidy, keep the maintenance access route unblocked, and ensure

that the warning and guiding signs are clear and intact.

Monitor the temperature of the battery module and clean the battery module if necessary.

6.1.3

Cable, Terminal and Equipment Inspection

(Every six months to one year)

➢

Check if the cable connections are loose.

➢

Check whether the cables are aged / damaged.

➢

Check whether the cable tie of the cable has fallen off.

➢

Check if the cable terminal screws are loose and the terminal position has any signs of

overheating.

➢

Check whether the management system of the system equipment, monitoring system and

other related equipment are invalid or damaged.

➢

Check that the grounding of the equipment is good and the grounding resistance is less than

10 ohms.

6.2

Notes