27

Subject to change without notice | 83031200dUK | ait-deutschland GmbH

-F1

0

-F1

3

A1

A2

-K1

3

-F

14

A1

A2

-K

14

-F

11

A1

A2

M

ZI

P

M

Z

UP

ZIP

ZW

2

M

X

52

-X8

N

5

ZW2/SST

A6

ZW

1

Z

W1

K

13

1

0

-X

5

4

X1

/X5

F

10

5

5

F

11

L1

A1

5

3~N/PE/400V/50Hz

PE

TB1

HUP

BU

P

TA

11

-X

12

A2

H

UP

X

8

PE

-X1

MZ1

N

PE

Z

W

2/S

S

T

Z

W2

4

R

FV

MI

S

7

A1

L

M

-X0

2

N

A3

V

B

O

Z

UP

-X

3

-X2

Air

water

outside

X7

T

BW

1

MA1

E

V

U

HUP

3

7

A

4

GND

2

9

3~PE/400V/50Hz

FP1

BUP

N

T

er

m

in

als

Z

W1

N

am

e

MOT

1

2

TBW

8

3

PE

6

A2

GND

A4

X

0-

X

4

VBO

ZUP

8

3

1

B

UP

A3

A6

1

1

ZW

2

X

12

Z

IP

In

fo

rm

at

io

n

o

n f

us

es

c

an

b

e f

ou

nd

in

th

e t

ec

hn

ic

a

l d

at

a

-X

52

F1

4

-X7

Z

W1

K

14

A5

A5

3~N/PE/400V/50Hz

RFV

F1

3

L1

TB1

L1

ZW1

-X4

RFV

F

P1

N

M

OT

2

T

B1

1~N/PE/230V/50Hz

E

VU

GND

T

RL

B10 A

9

M

A

1/M

IS

TA

GND

P

EX

TA

Le

g

e

n

d:

ASD

TBW

TRL

PE

GND

GND

1

04

12

PEX

6

EVU

MZ

1/MI

S

U

K

83

1164

F

unc

tion

C

ont

rol

ler

boar

d;

A

ttent

ion:

I

-m

ax

=

6

A

/23

0V

A

C

H

eat

pu

m

p

S

ub-

di

str

ibu

tion

uni

t i

nt

er

n

al

ins

tal

lat

ion

T

er

m

in

al

s i

n

sw

itc

h

box

w

al

l r

egul

at

or

H

ot

w

a

ter

o

r buf

fe

r s

tor

age

tank

H

ot

w

a

ter

o

r buf

fe

r s

tor

age

tank

3-

pol

. C

u

t out

c

om

pr

es

sor

; A

ttent

ion:

R

ight

-hand

rot

. fi

el

d i

s m

andat

or

y!

C

ut

ou

t c

ont

rol

ler

uni

t

C

ut

o

ut

a

ux

ilia

ry

heat

ing

1

C

ut

ou

t

a

ux

ili

a

ry

heat

ing

2

C

ont

ac

tor

el

e

ctr

ic

he

at

in

g

el

e

m

ent

b

uf

fe

r t

ank

C

ont

ac

tor

el

e

ctr

ic

he

at

in

g

el

e

m

ent

h

ot

w

at

er

or

bu

ffer

tank

H

ot

w

a

te

r c

irc

ul

ati

ng

pum

p/

sw

itc

hi

ng

v

al

ve

E

ne

rgy

s

uppl

ier

c

ont

ac

t; c

los

e

d on

rel

eas

e;

br

idg

e i

f n

o

bl

oc

king

int

e

rv

al

P

ump

for

m

ix

in

g

ci

rcu

it

1

H

eat

ing

c

irc

ui

t c

irc

ul

at

ing

pum

p

C

har

ge/

di

sc

har

ge/

cool

ing

m

ix

e

r 1

o

pen

C

har

ge/

di

sc

har

ge/

cool

ing

m

ix

e

r 1

c

los

e

d

O

ver

loa

d pr

ot

ec

tion;

in

ter

nal

ly

w

ire

d

N

o f

unc

tion

A

cc

es

sor

ies

: R

em

ot

e

cont

rol

E

xter

nal

s

ens

or

S

en

sor

m

ix

ing

c

irc

ui

t 1

Ho

t

w

a

ter

gaug

e/

ther

m

os

tat

E

xter

nal

ret

ur

n s

ens

or

V

en

tilat

or

; i

nt

er

na

lly

w

ired

T

er

m

in

al

stri

ps

on

con

trol

le

r boar

d (

see

s

tic

ker

)

P

lugs

on

c

on

trol

ler

boar

d (

see

s

tic

ke

r)

T

er

m

in

al

s

trip

in

s

w

itc

h

box

w

al

l r

egu

lat

or

; N

/P

E

di

str

ibut

ion

for

ex

te

rnal

2

30V

de

vic

es

D

is

tribut

ion

box

in

h

eat

pum

p

;

pow

er

sup

pl

y

out

put

co

m

pr

es

sor

P

lug

on

s

w

itc

h b

ox

hea

t pum

p

(c

ont

rol

line

)

P

lu

g

on

sw

itc

h

b

ox

hea

t

pum

p

(g

au

ge

lin

e)

Auxiliary

circulation

pump

C

irculation

pump

C

ont

rol

s

ignal

of

add

itional

heat

g

en

er

at

or

1

C

ont

rol

s

ignal

of

add

itional

heat

g

en

er

at

or

2

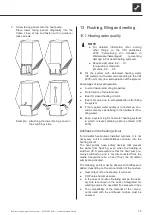

T

er

m

inal

di

agr

am

LW

250A

/ 310A

8311

64

A

chi

m

P

fle

g

er

0

4.12

.20

09

-

P

EP

0

20

/2

00

9

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

/1

1

0

4.1

2.

20

0

9

1

0X

449;

A

chi

m

P

fleg

er

10X

547;

B

la

tt-N

r.

Z

us

ta

nd

Ä

nde

ru

n

g

B

ea

rb.

D

at

u

m

N

am

e

B

l v

o

n A

n

z

D

at

u

m

LW 300A

Terminal diagram